For English ¿Habla español? Parlez-vous français?

See page 2 Ver página 38 Voir page 74

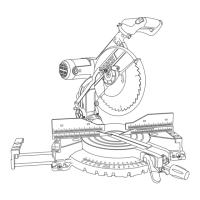

4212L

Operating/Safety Instructions

Instrucciones de funcionamiento y seguridad

Consignes de fonctionnement/sécurité

IMPORTANT: IMPORTANTE: IMPORTANT :

Read Before Using Leer antes de usar Lire avant usage

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free

for Consumer Information

& Service Locations

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

Pour renseignement des

consommateurs et centres

de service, appelez au

numéro gratuit :

BM 2610924645 08-04 E 9/2/04 10:48 AM Page 1