1 689 989 112 2020-06-24| Robert Bosch GmbH

| BEA 060 | 25 | en

5. Maintenance

! Work on electrical equipment is only to be

performed by persons with sufficient knowledge

and experience of electrical systems!

5.1 Cleaning

! Do not use abrasive cleaning agents and coarse

workshop cloths!

¶ The housing and the LCD are only to be cleaned

using a soft cloth and neutral cleaning agents.

5.2 Calibration

For applications demanding mandatory calibration,

regular calibration is essential. (depending on the

regulations of the respective country).

5.3 Service intervals

i Routine maintenance ensures constant readiness

for operation.

The following maintenance intervals are to be

observed unless otherwise specified by the approval

authorities.

5.3.1 Half-yearly maintenance

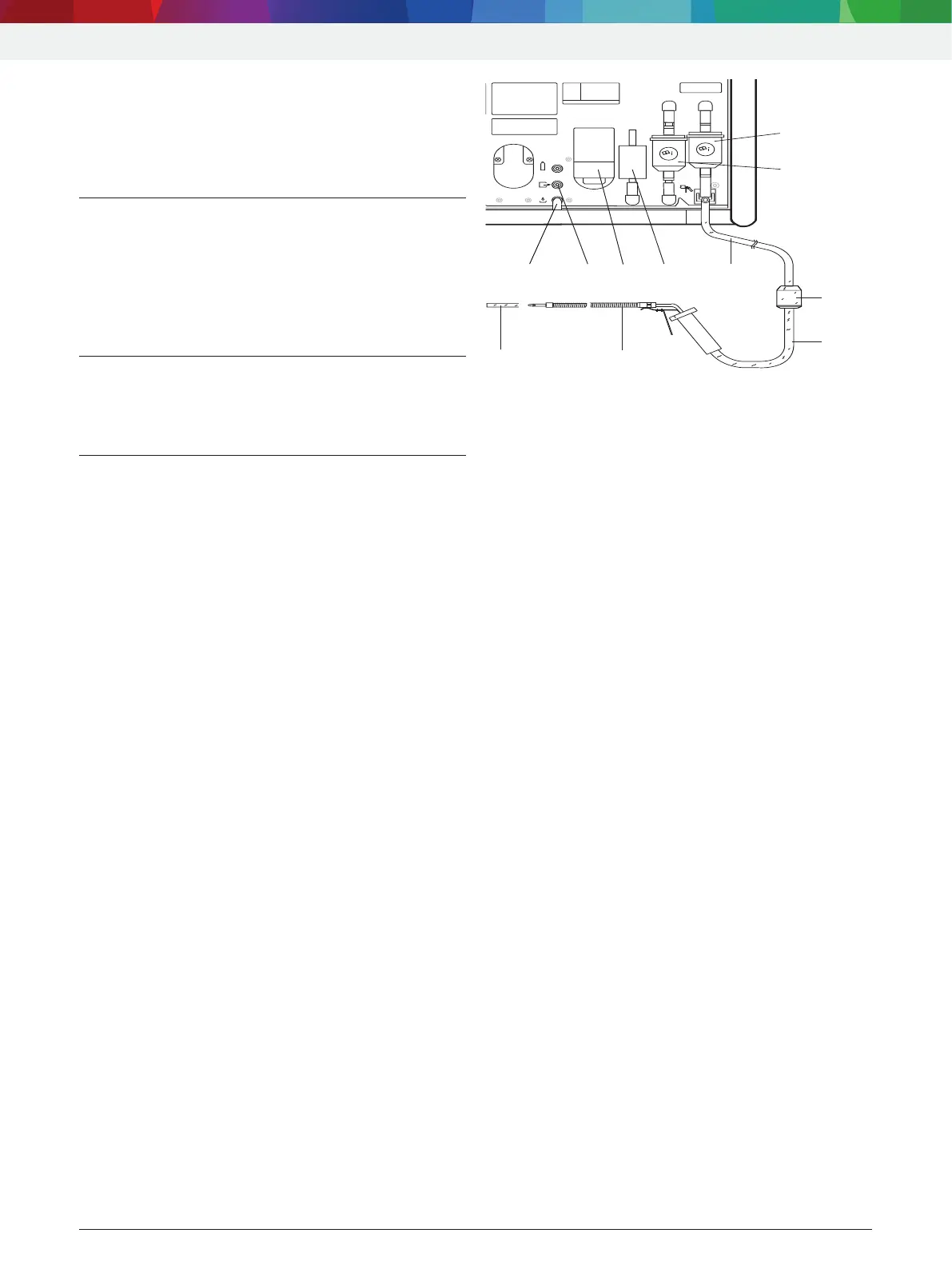

¶ Replacement of coarse filter GF1 (fig. 3, pos. 8) in

sampling hose.

¶ Replacement of coarse filter GF2 (fig. 3, pos. 1),

refer to Section 5.4.4.

¶ Check whether both PVC hoses are connected to

the gas outlets (fig. 4, pos. 6 and 7).

¶ Visual inspection of sampling probe (fig. 3, pos.10).

¶ Sampling probe leak test (refer to Section 5.4.1).

5.3.2 Annual maintenance

This work is to be performed by a qualified

maintenance service. It includes the half-yearly

maintenance and the following additional items:

¶ Checking of BEA 060 measurement accuracy with

atest gas.

¶ Replacement of activated charcoal filter (fig. 3,

pos. 4) in zero gas path.

¶ Replacement of coarse filter GF3 (refer to

Section5.4.4)

Compliance with the specifications of the relevant

authorities must be ensured.

O2

N0

AF I

GF 3 GF 2

BEA 060

459907_4Ko.eps

11

10

9

8

3

7

5

4

2

1

6

11-16V

20 W

Fig. 3: BEA 060

1 Coarse filter GF2

2 Coarse filter GF3

3 8 m hose

4 Activated charcoal filter AF1

5 O

2

sensor

6 Measurement gas outlet (transparent PVC hose)

7 Gas outlet and condensate outlet (transparent PVC hose)

8 Coarse filter GF1

9 30 cm Viton hose (black)

10 Exhaust gas sampling probe

11 Plastic hose for leak test

Loading...

Loading...