Climate 5000 8736862495(2015/07)

Unit installation | 11

3.5 Installation and connection of steam

coil pipe

Working pressure of steam coil shall not be ex-

cessive, wherein the steam inlet and outlet pipe is

connected through pipe thread or flange, and the

connection type of steam inlet pipe is up-in and

down-out(→Fig. 13-1, 2).

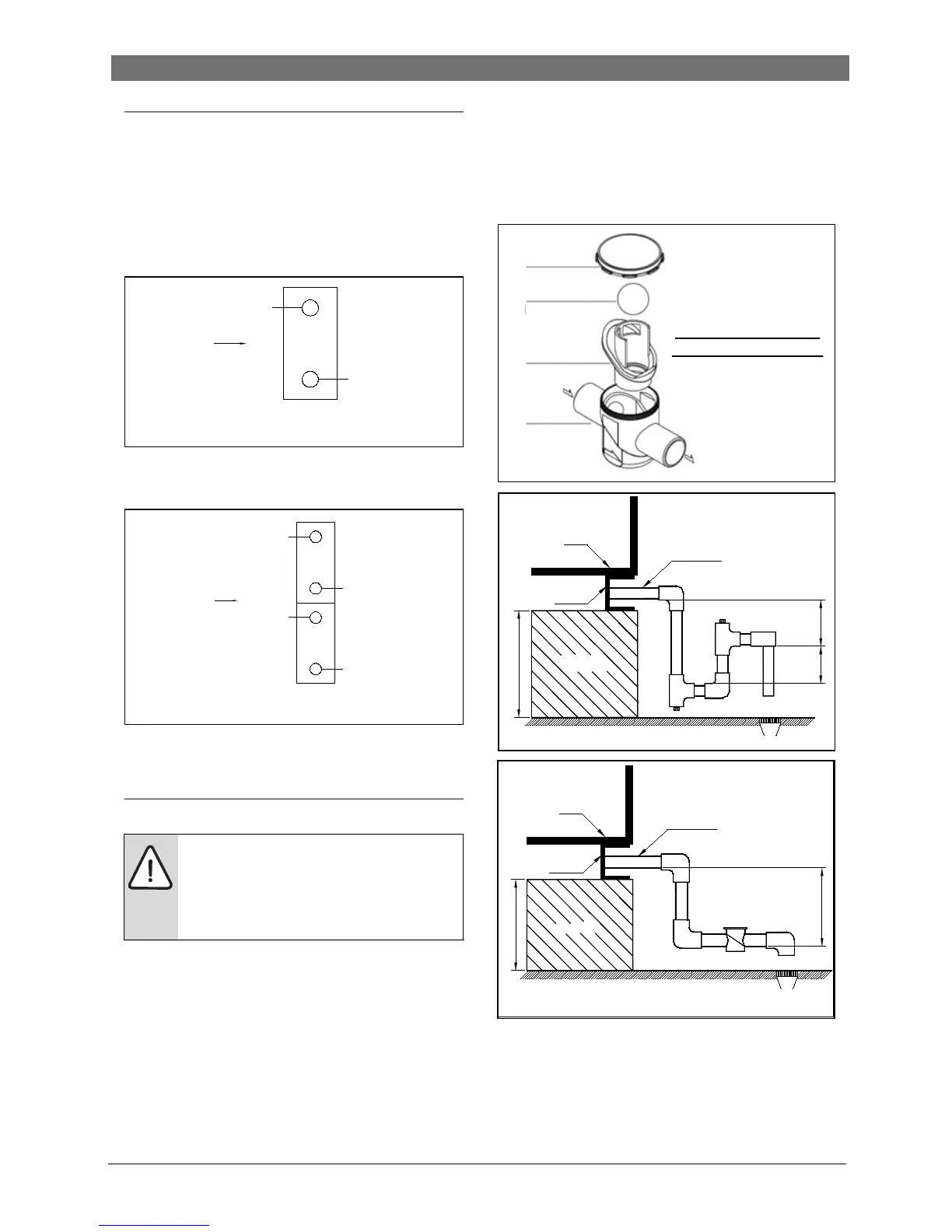

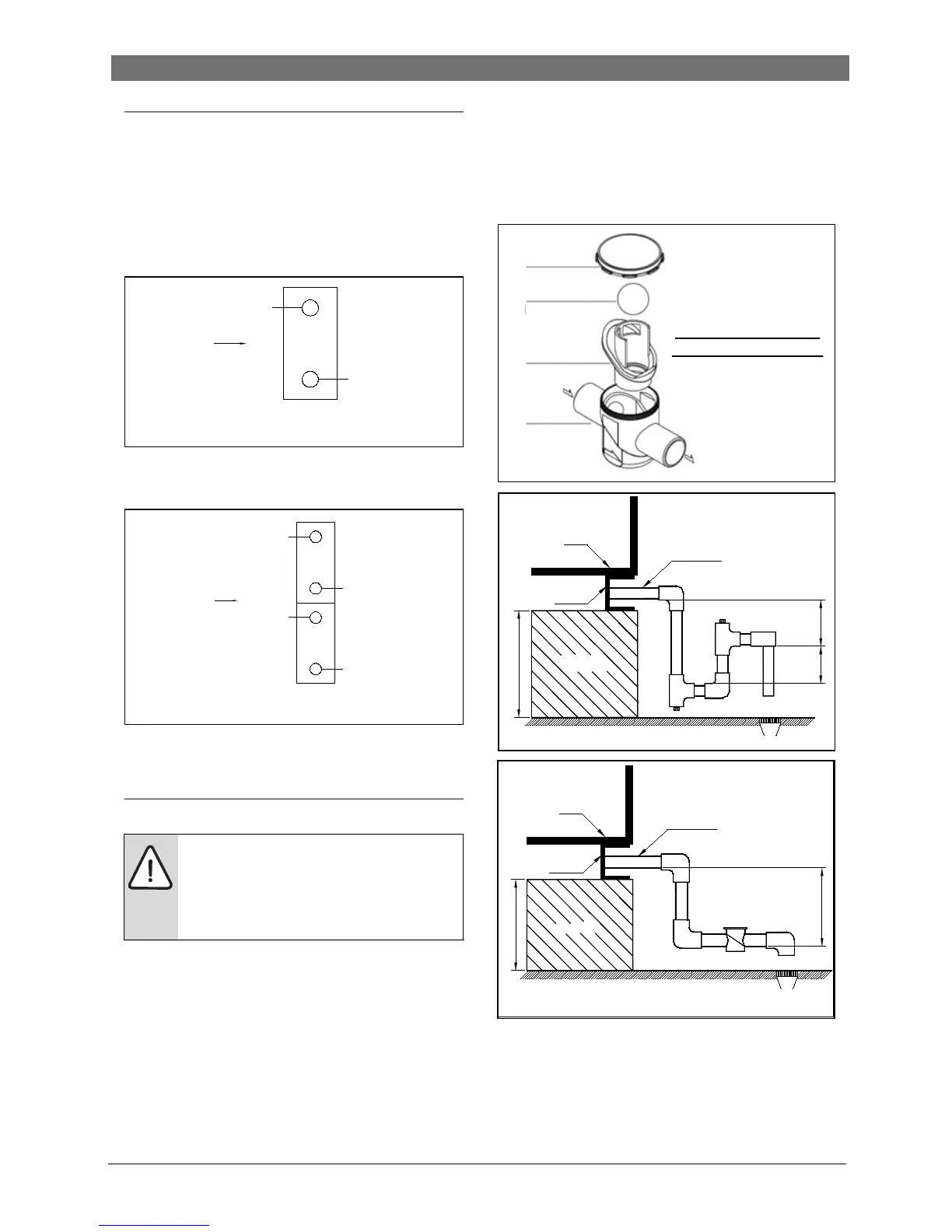

Fig. 13-1 Schematic diagram of inlet and outlet

pipe installation of steam coil( single layer stream

heater)

Fig. 13-2 Schematic diagram of inlet and outlet

pipe installation of steam coil( double layer stream

heater)

3.6 Installation of siphon

For each of condensate pipes and overflow pipes,

one siphon must be applied. Several condersate

pipes sharing one siphon is not allowed. For the

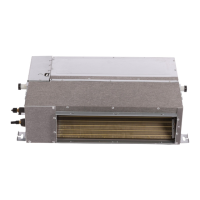

installation of siphon please refer to Fig. 14

(siphon provided by the buyer or floating ball

siphon purchased from Bosch (optional).

When the MAHU is operating, U siphon will fails

when the unit is running dry. Due to the condition,

we recommend to use floating ball siphon (a self-

filling siphon for drainage of heat exchangers,

humidifiers, and other wet regions at a pressure

lower than ambient pressure, it contains a floating

ball which prevents the intake of air so that the

first accumulating condensate produced can fill

the siphon) for the alternative U siphon for the

problem mentioned below.

Fig. 14 Schematic diagram of floating ball siphon

installation

• Characteristics of floating ball siphon

- Avoid odor flooding and insects entering.

- Maintenance port is equipped for the conve-

Loading...

Loading...