Installation

53

Climate 5000L • Climate 5000i U/L – 6721841492 (2022/03)

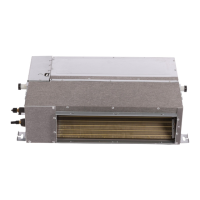

3.5.2 Connecting condensate pipe to the indoor unit

Depending on the type of installation, the condensate pipe must either

be connected to the integrated condensate pump or the condensation

catch pan.

▶ Use PVC pipes with 32 mm inside diameter and 5-7 mm wall

thickness.

▶ Insulate drain pipe to prevent condensate formation.

▶ Connect drain pipe to indoor unit and secure connection with a hose

clip.

▶ Install drain pipe on slope ( Fig. 25). With a condensate pump

installed, the outlet of the drain pipe may be higher than the indoor

unit if the dimensions and wiring diagram are observed.

NOTICE

Danger due to water damage!

If the pipes are routed incorrectly, water may be discharged, or may flow

back into the indoor unit and cause the water level switch to malfunction.

▶ To prevent the pipes from sagging, install a support every 1–1.5 m.

▶ Route a drain pipe to the sewer via a siphon.

3.5.3 Testing the condensate pipe

Testing the condensate pipe ensures that all connections are tight.

▶ Test the condensate pipe before closing the cover.

if the condensate pump can only be tested once the electrical connection

has been established.

▶ Fill the condensation catch pan or water injection pipe with roughly

2l of water.

▶ Switch on cooling mode. The drainage pump can be heard.

▶ Make sure that the condensate drains away properly.

▶ Check tightness of all connections.

3.5.4 Checking tightness and filling the system

Checking tightness

Observe the national and local regulations when carrying out the

tightness test.

▶ Remove the caps of the valves of a connection pair

( Fig. 14 and 15, [1], [2] and [3]).

▶ Connect the Schrader opener [6] and pressure gauge [4] to the

service socket [1].

▶ Open Schrader valve [1].

▶ Leave valves [2] and [3] closed and fill the pipes with nitrogen until

the pressure is 10% above the maximum operating pressure

( Page 60).

▶ Check whether the pressure is still the same after 10 minutes.

▶ Discharge the nitrogen until the maximum operating pressure is

reached.

▶ Check whether the pressure is still the same after at least 1 hour.

▶ Discharge nitrogen.

Filling the system

NOTICE

Malfunction due to incorrect refrigerant

The outdoor unit is filled with refrigerant R32 at the factory.

▶ If refrigerant needs to be topped up, only use the same refrigerant.

Do not mix refrigerant types.

▶ Evacuate and dry the pipes with a vacuum pump ( Fig. 14 and 15,

[5]) for at least 30 minutes at roughly −1 bar (approx. 500 microns).

▶ Open valve [3] on liquid side.

▶ Use a pressure gauge to [4] check whether the flow is unobstructed.

▶ Open valve [2] on gas side.

The refrigerant is distributed round the connected pipes.

▶ Afterwards, check the pressure ratios.

▶ Close Schrader valve [1] on the service socket side.

▶ Remove the vacuum pump, pressure gauge and Schrader opener.

▶ Reattach the valve caps.

▶ Reattach the cover for pipe connections to the outdoor unit.

3.6 Electrical connection

3.6.1 General notes

WARNING

Risk to life from electric shock!

Touching live electrical parts can cause an electric shock.

▶ Before working on electrical parts, disconnect all phases of the

power supply (fuse/circuit breaker) and lock the isolator switch to

prevent unintentional reconnection.

▶ Work on the electrical system must only be carried out by an

authorised electrician.

▶ An authorised electrician must determine the correct conductor

cross-section and circuit breaker. The maximum current

consumption of the technical data ( see chapter 9, page 60) is

decisive for this purpose.

▶ Observe safety measures according to national and international

regulations.

▶ If you identify a safety risk in the mains voltage, or if a short circuit

occurs during installation, inform the operator in writing and do not

install the appliances, until the problem has been resolved.

▶ All electrical connections must be made in accordance with the

electrical connection diagram.

▶ Only use a special tool to cut cable insulation.

▶ Connect the cable to the existing mounting clips / cable glands using

suitable cable ties (scope of delivery).

▶ Do not connect any additional consumers to the mains power supply

of the device.

▶ Do not mix up live and PEN conductor. This can lead to malfunctions.

▶ If the mains power supply is fixed, install an overvoltage protector

and isolator which is designed for 1.5 times the maximum power

input of the appliance.

▶ For devices with a fixed mains power supply in which the leakage

current is potentially higher than 10 mA, we recommend installing a

residual current device (RCD) with a maximum rated residual

operating current of 30 mA.

Loading...

Loading...