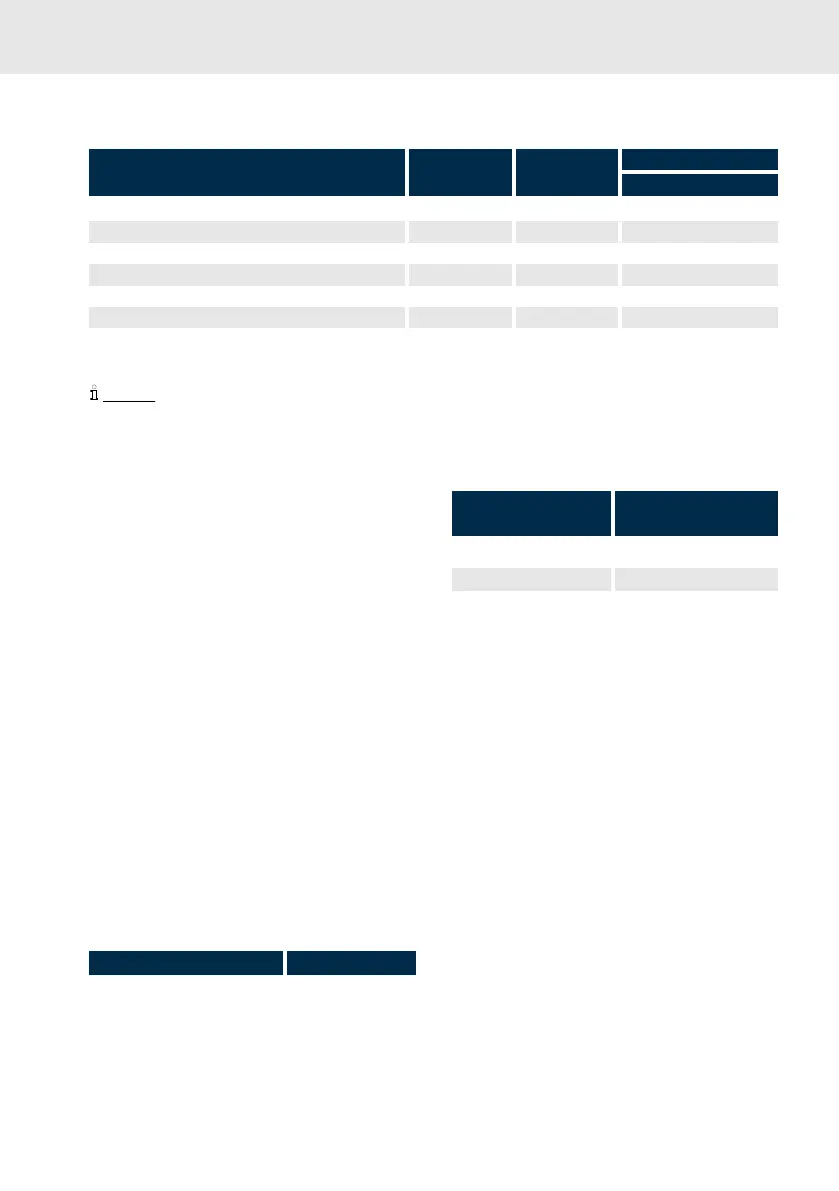

Table 7: Technical data of encoder

Designation

Symbol Unit

Encoder

IM

Encoder interface - - ctrlX SENSE

motor

Functional encoder resolution (singleturn) - 18 bit

Distinguishable rotations U

turn

- 65,536

Maximum system accuracy of encoder

1)

∢ '' ± 360

Encoder voltage supply VCC

Encoder

V 8...12

Encoder max. current consumption I

Encoder

mA 130

1) The installation mechanics can sporadically influence the accuracy of the overall system.

Remark: These motors are suited for applica-

tions with STO safety function within the electric

drive system with ctrlX DRIVE according to

EN IEC 61800-5-2.

5.2.6 Degree of protection

The protection type according to EN 60034-5 is

determined by the abbreviation IP (International

Protection) and two code numbers for the degree

of protection. The first code number stands for

the degree of protection against contact and

ingress of foreign bodies. The second code

number stands for the degree of protection

against ingress of water.

Standard motors (specification according to type

plate)

• IP65 with shaft sealing ring

5.2.7

Output shaft, balancing and

extension elements

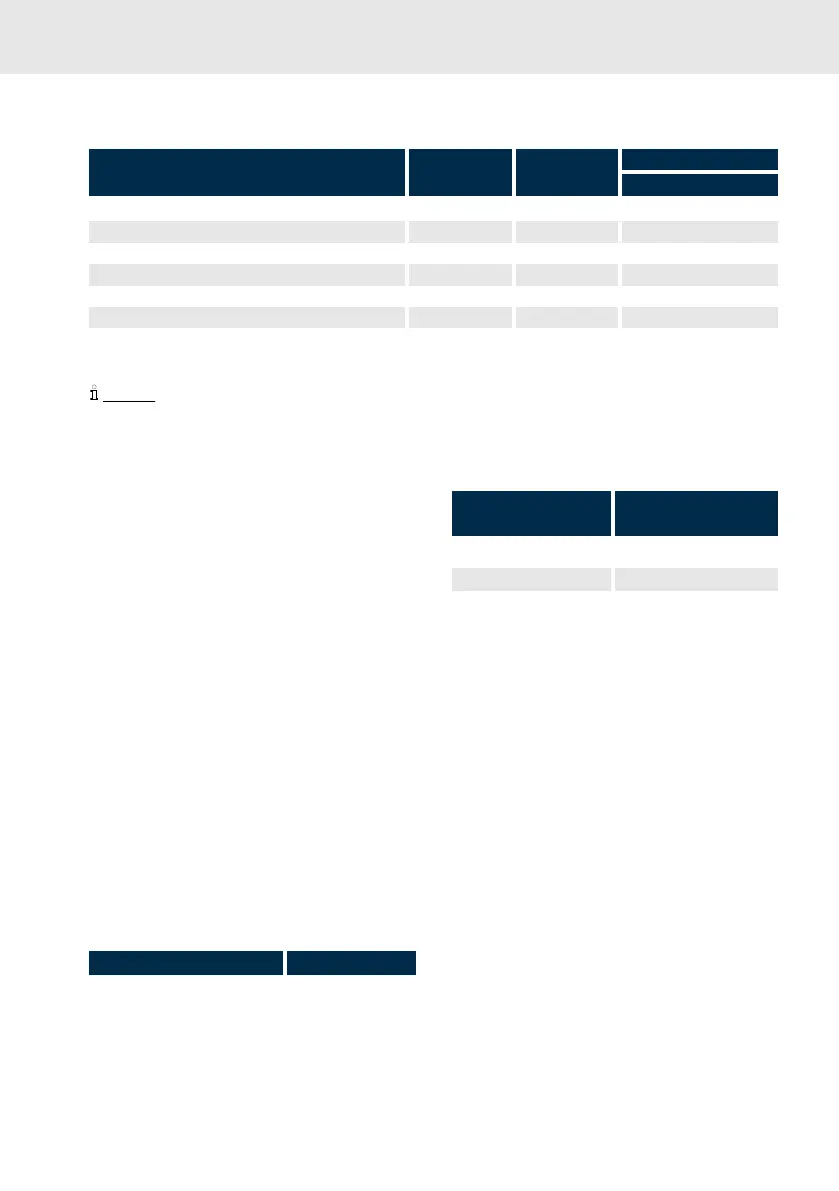

Shaft end

Options according to type code

Shaft Type

Smooth, with shaft sealing

ring

G

Smooth shaft

Cylindrical shaft end according to DIN 748-3 with

frontal centering hole with "DS" thread according

to DIN 332-2.

Type Centering hole DIN 332

Part 2

MS2S03 DS M3

MS2S04 DS M5

MS2S05 DS M6

The standard design for a non-positive shaft-hub

connection without play and excellent smooth

running. Use clamping sets, pressure sleeves or

clamping elements for coupling the machine ele-

ments to be driven.

The shaft sealing ring affects the degree of pro-

tection. We recommend regular visual inspec-

tions on shaft sealing rings. Depending on oper-

ating conditions, signs of wear may appear after

5,000 operating hours. If necessary, replace the

shaft sealing rings.

Attachment of drive elements

The mode of balancing of drive elements must be

adjusted to the motor. Observe the notes about

mounting drive elements.

Loading...

Loading...