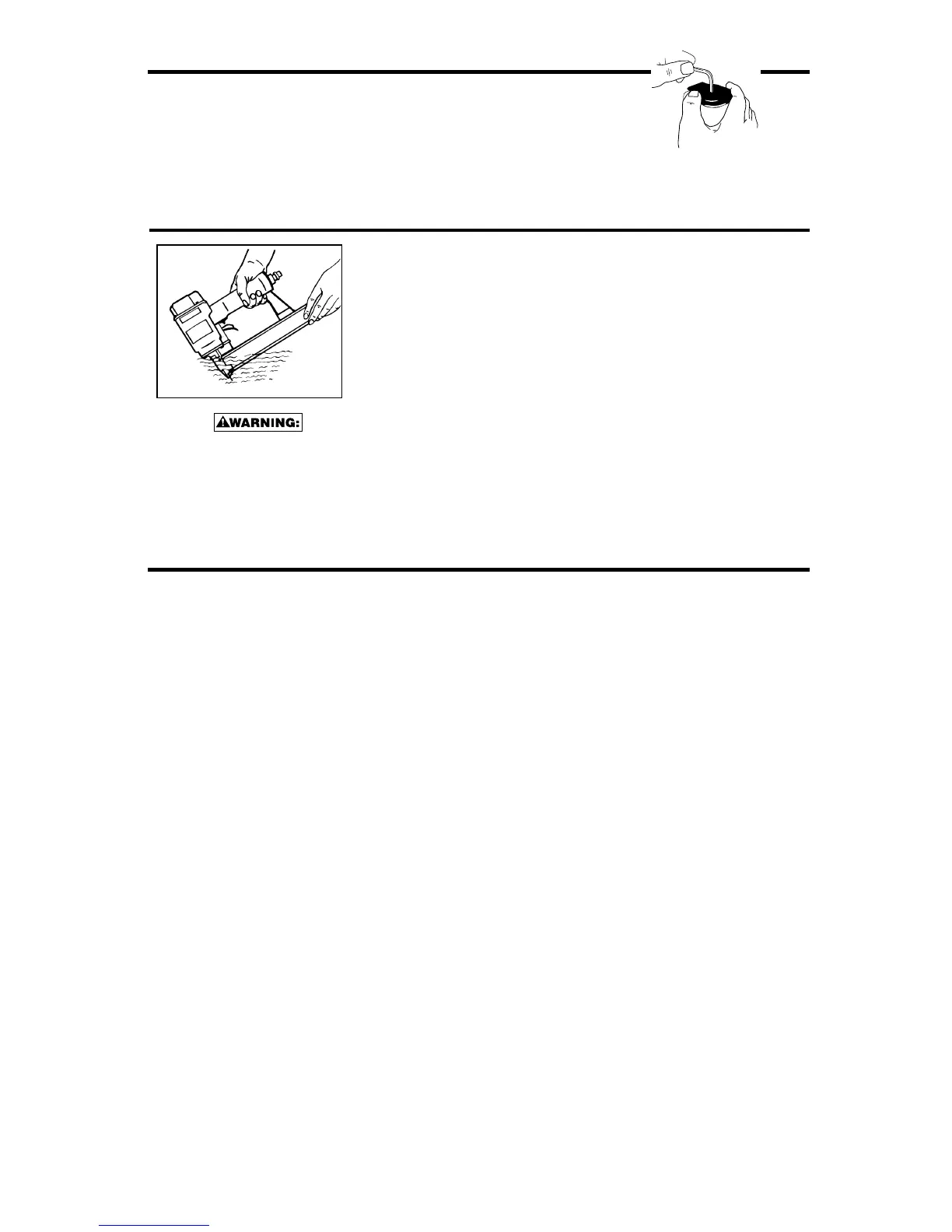

DIRECTIONAL EXHAUST DEFLECTOR

ACCESSORIES AVAILABLE

Loosen screw as shown. Adjust to desired exhaust

direction and tighten screw.

BC602 1 pint General Purpose Air-Tool Lubricant.

BC603 1 pint “Winter Formula” Air-Tool Lubricant.

BC604 1 quart General Purpose Air-Tool Lubricant.

100679 O-Ring lube 1 lb. can

851487 4mm Hex Wrench, long pattern for M5 screws

ORK1 Kit, O-Ring

BK6 Kit, Bumper

BK7 Kit, Bumper (T40/T50)

851325 Loctite #271, 0.5cc packet

N80K2 Remote Fire Kit

102475 Kit, Frame Protector

CLEANING T40S2 STAPLERS USED WITH ASPHALT SHINGLES

Tar and dirt may build up on the nose and contact arm. This can pre-

vent correct operation. Remove any buildup with kerosene, #2 fuel oil

or diesel fuel. Do not immerse the stapler into these solvents beyond

the bottom of the frame to avoid getting the solvent into the drive cylinder.

As an aid in cleaning or to help remove a jam if necessary, the nose

may be opened by inserting a screwdriver into the drive channel and

prying to pop open the door.

Dry off the stapler before use. Any oil film left after cleanup will acceler-

ate the tar buildup, and the stapler will require more frequent re-cleaning.

Do not use gasoline or similar highly flammable liquids to clean the tool.

Vapor in the tool could be ignited by a spark causing the tool to explode.

NOTE: Solvents sprayed on nose to clean and free up the trip may have

the opposite effect! The solvent may soften the tar on the shingles and

cause tar buildup to be accelerated. Dry operation is better, as noted

above.

-12-

Loading...

Loading...