Troubleshooting

7-7

Digital Compact

2002 BRANSON Ultrasonics Digital Compact Version 22.08.2002

7.2.5 Conditioning of the Mating Surfaces of the Acoustic Stack

To achieve optimum operation of the components of a welding system

it is necessary that the mating surfaces of the acoustic stack are plane,

have proper contact and are free of frictional corrosion.

Improper contact of the mating surfaces results in power output losses,

difficulties when tuning, generation of additional heat and noise, and

increasing danger of damage to the converter.

When cleaning the acoustic stack, please proceed as follows:

CAUTION!

Take greatest care when conditioning. In case of improper condi-

tioning the components can be damaged. If in doubt, send the

components to BRANSON Ultrasonics.

1. Disassemble the acoustic stack and clean the mating surfaces

using a dry cloth or paper towel.

2. Inspect all mating surfaces. In case you detect fretting corrosion or

a hard dark deposit on one of the mating surfaces, please proceed

as follows:

3. If necessary, remove the horn stud from the component.

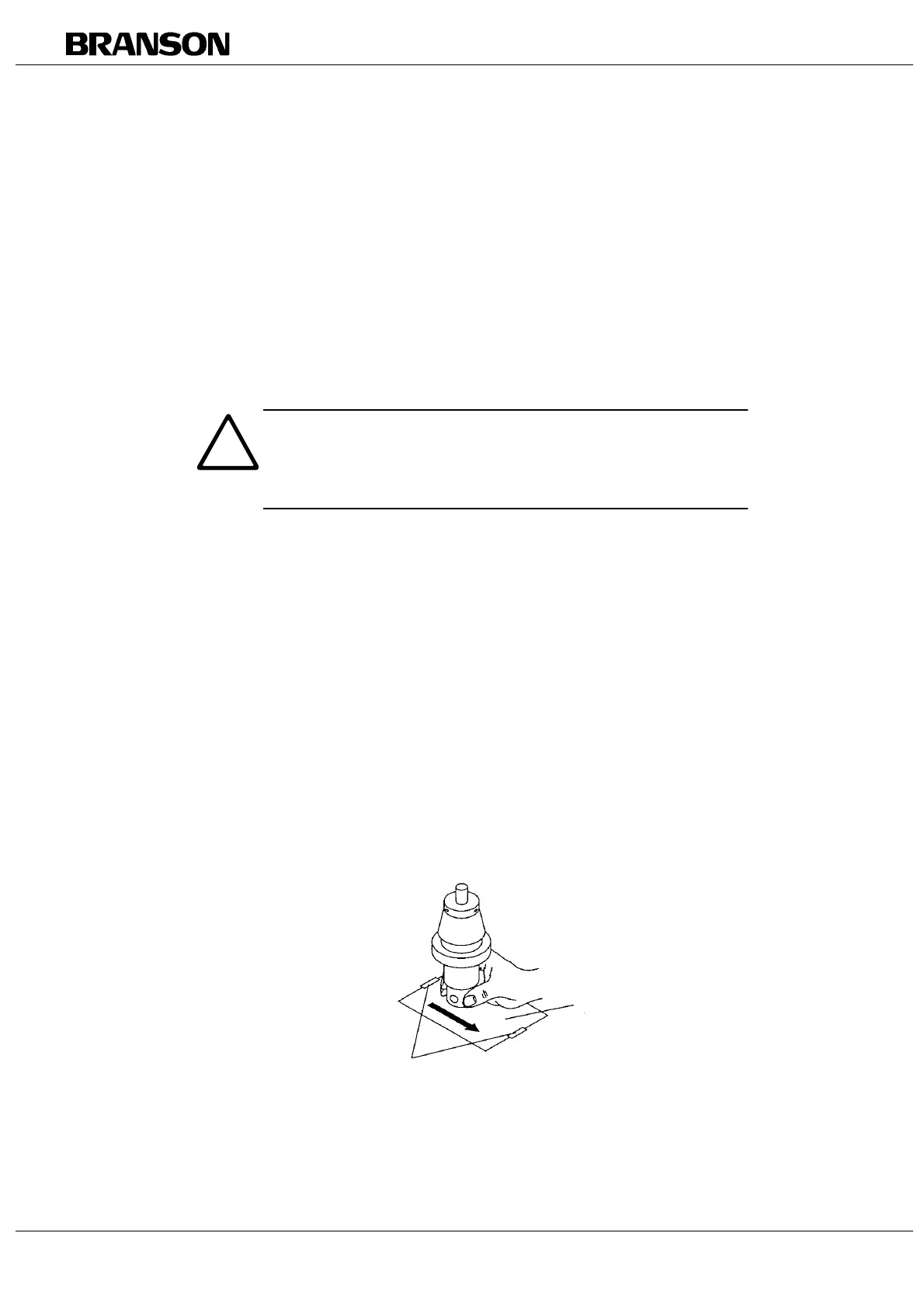

4. Use adhesive tape to fix a proper piece of emery cloth grade 400

(or finer) on a plane and clean surface (e. g. glass plate).

5. Place the component’s mating surface on the emery cloth. Hold the

component at the bottom with the thumb over the blind hole and

move the component carefully lengthways to lap it on the emery.

There is no need to apply downward pressure, the weight of the

component is sufficient.

Fig. 7-2 Cleaning the mating surfaces using emery cloth

!

Emery cloth

Adhesive tape

Loading...

Loading...