All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their

application.

Series 6A Installation, Operation & Maintenance – Field Connections

6A O & M : 10

Natural Gas as an Actuator Medium

The S6A can also be operated with natural gas as an actuator

medium. When operating the positioner with natural gas, you

must follow and adhere to the following safety notes:

1. Only the “EEx ia” version of the positioner and optional

modules with the “EEx ia” type of protection may be

operated with natural gas. Positioners with other types of

protection, i.e. flameproof enclosures for zones 1 and 2 are

not permitted.

2. Do not operate the positioner with natural gas in closed

spaces.

3. Natural gas is continuously blown off in the servo-drive

depending on the model. Special care must therefore be

taken during maintenance activities near the positioner.

Always ensure that the immediate surroundings of the

positioner are adequately ventilated.

4. The mechanical limit switch module may not be used when

operating the positioner with natural gas.

5. Depressurize the devices operated with natural gas

adequately during maintenance activities. Open the cover in

an explosion-free atmosphere and depressurize the device

for at least two minutes.

Normally you operate the positioner with compressed air.

Natural gas has been approved as an actuator medium for

intrinsically safe positioners with the “EEx ia” type of protection.

Only use natural gas which is clean, dry and free from additives.

The positioner releases the used natural gas through the

exhaust air outlet E (see Figure 2). The exhaust air outlet E is

equipped with an attenuator. As an alternative to this standard

configuration, the exhaust air outlet can be replaced with a G¼

screwed fitting. You have to dismantle the attenuator for this

purpose. Natural gas escapes parallel to the exhaust air outlet

E, from the enclosure vent at the bottom side of the device, and

from the control air outlet near the pneumatic connections.

This escaping natural gas cannot be collected and carried off.

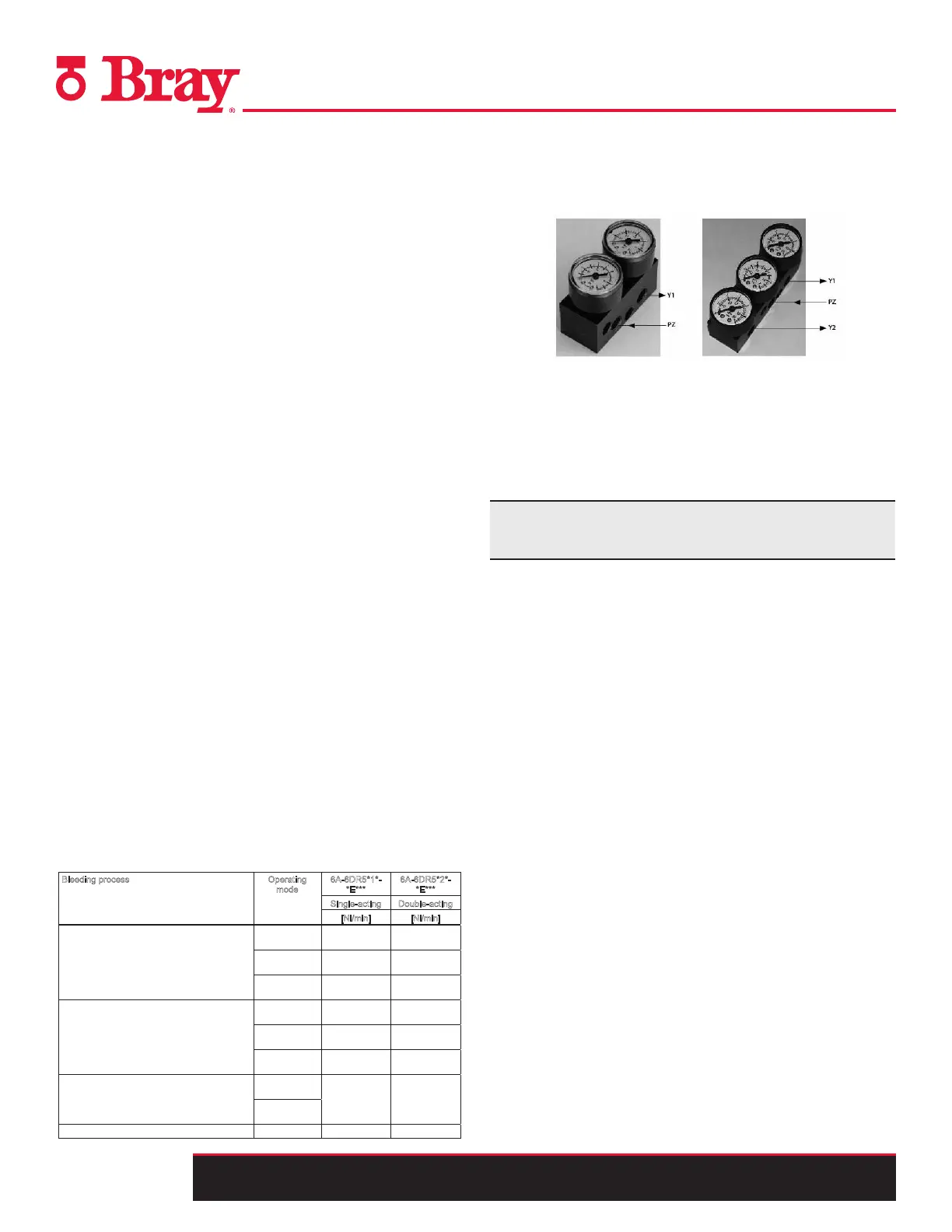

When using natural gas as an actuator medium refer to Figure

5 for maximum bleed off values.

6A-6DR5*1*-

*E***

6

A-6DR5*2*-

*E***

Single-acting Double-acting

Bleeding process Operating

m

ode

[

Nl/min] [Nl/min]

Operation,

typical

0.14 0.14

Operation,

max.

0.60 0.60

Bleed the enclosure volume through the bottom

side of the device. Purge air switch is at "IN":

Error case,

max.

60.0 60,0

Operation,

typical

1.0 2.0

Operation,

max.

8.9 9.9

Bleed through the control air outlet near the

pneumatic connections:

Error case,

max.

66.2 91.0

Operation,

max.

Bleed through the exhaust air outlet E

Error case,

max.

358.2

1)

339

1),

32.1 62.1 ]l[ .xaM emuloV

Figure 5. Maximim bleed off values

Optional Accessories

1. Pressure Gauges – used to measure and indicate supply

and actuating pressures

2. Filter – used to clean the supply medium

3. Non Contacting/External Position Detection System –

used for harsh environments

4. SIMATIC PDM Operation Software – used for online

diagnostics of the S6A

Contact your Bray representative for specific requirements

for your intended application.

Loading...

Loading...