All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their

application.

Series 6A Installation, Operation & Maintenance – Troubleshooting

6A O & M : 28

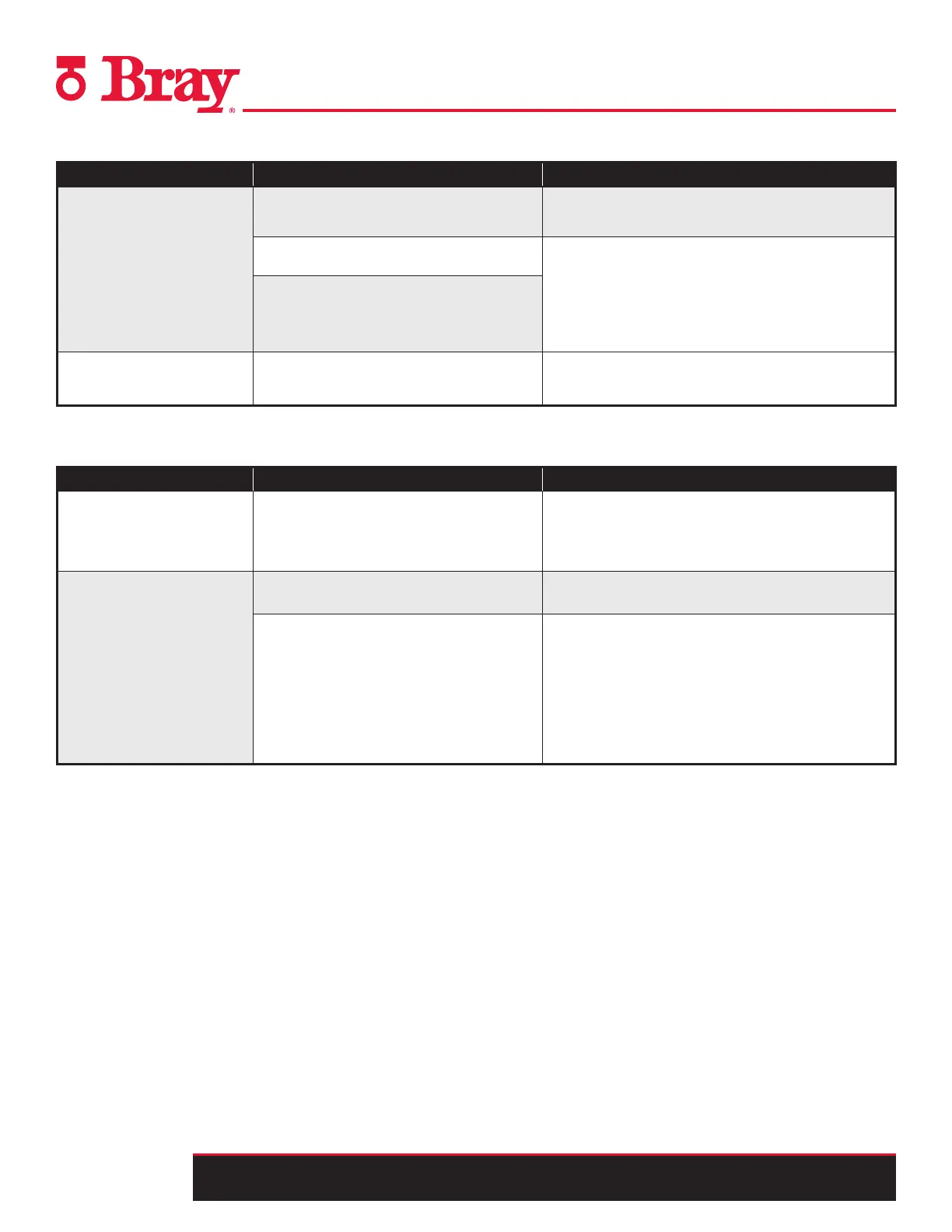

Fault profile (symptoms) Possible cause(s) Remedial measures

In stationary automatic mode

(constant setpoint) and in man-

ual mode, both piezo valves

continually switch alternately,

and the actuator oscillates

around a mean value.

Sticking friction of the packing gland from the

control valve or actuator too large

Reduce friction or increase dead zone of positioner

(parameter ”dEbA”) until the oscillation stops

Looseness (play) in the positioner/actuator/

control valve system

Part-turn actuator: Check for firm seating of set screw on

coupling wheel

Linear actuator: Check for firm seating of lever on

positioner shaft

Correct any other play between the actuator and the

control valve

Actuator is too fast

Positioner doesn’t move con-

trol valve to the stop (at 20

mA)

Supply pressure too low. Load on the feeding

controller or system output is too low

Increase supply pressure, insert ballast converter

Select 3/4-wire mode

Remedial Measures Table 4

Remedial Measures Table 5

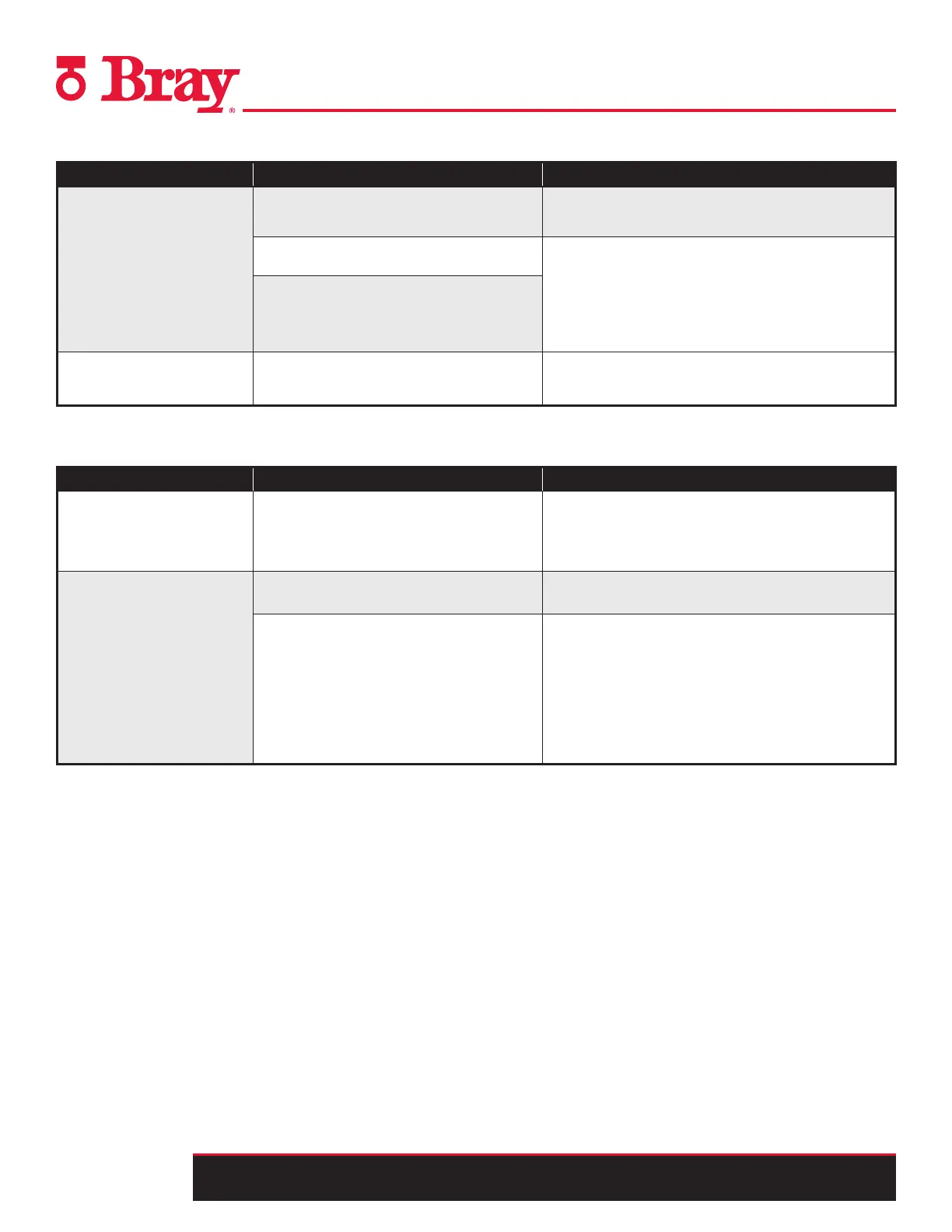

Fault profile (symptoms) Possible cause(s) Remedial measures

Zero point displaces sporad-

ically (> 3%).

Impact or shock loads result in accel-

erations so high that the friction clutch

moves, e.g. due to ”vapor shocks” in

vapor lines

Rectify the causes for shock loads

Re-initialize the positioner

The device function has

completely failed: no view

even on the digital display.

Electrical auxiliary power supply is not

adequate

Check the electrical auxiliary power supply

In case of very high continuous loads due

to vibrations (oscillations):

Screws of the electrical connecting termi-

nals may be loose

Electrical connecting terminals and/or

electronic components may be knocked

out

Tighten the screws firmly x

Repair

1)

For prevention: install the positioner on the damping pads

Loading...

Loading...