11

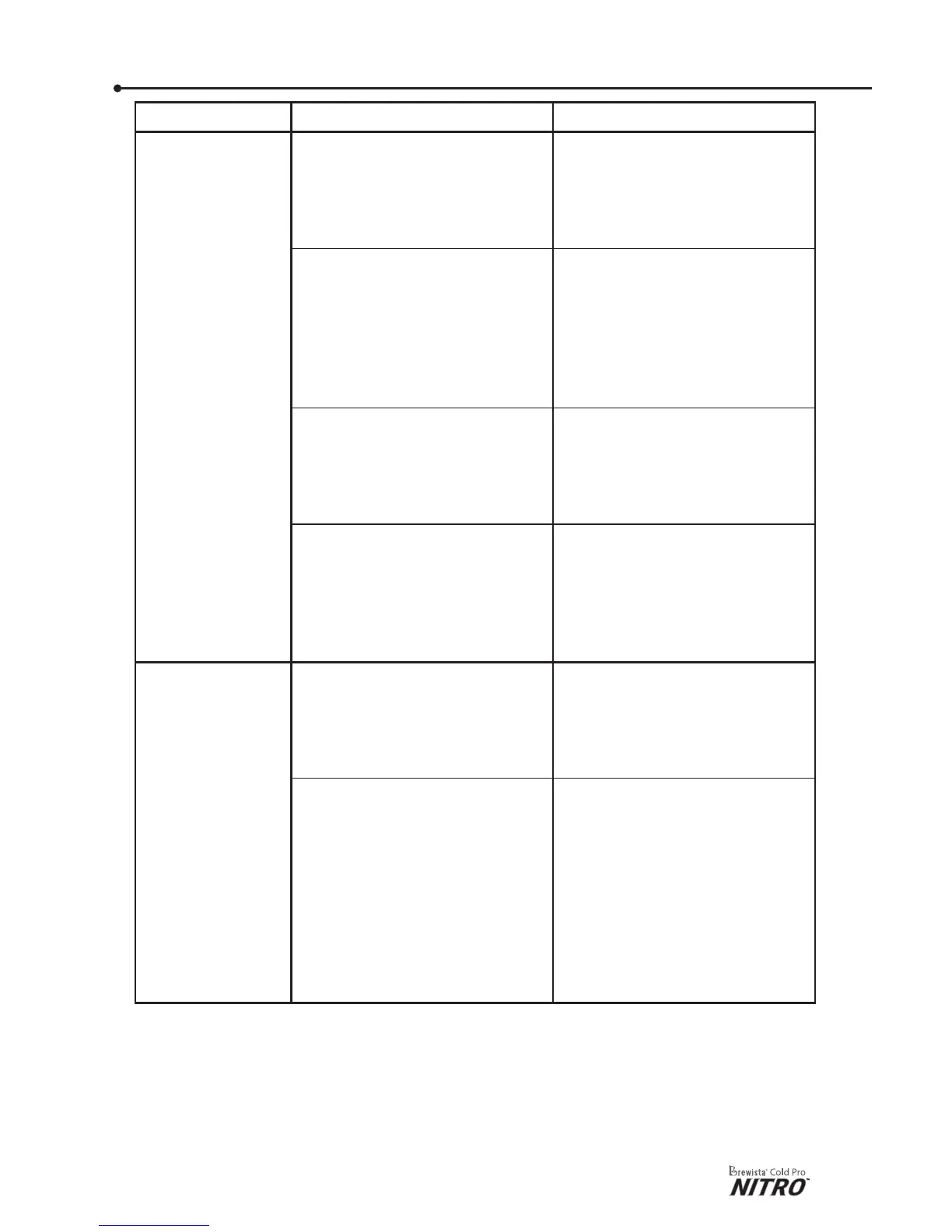

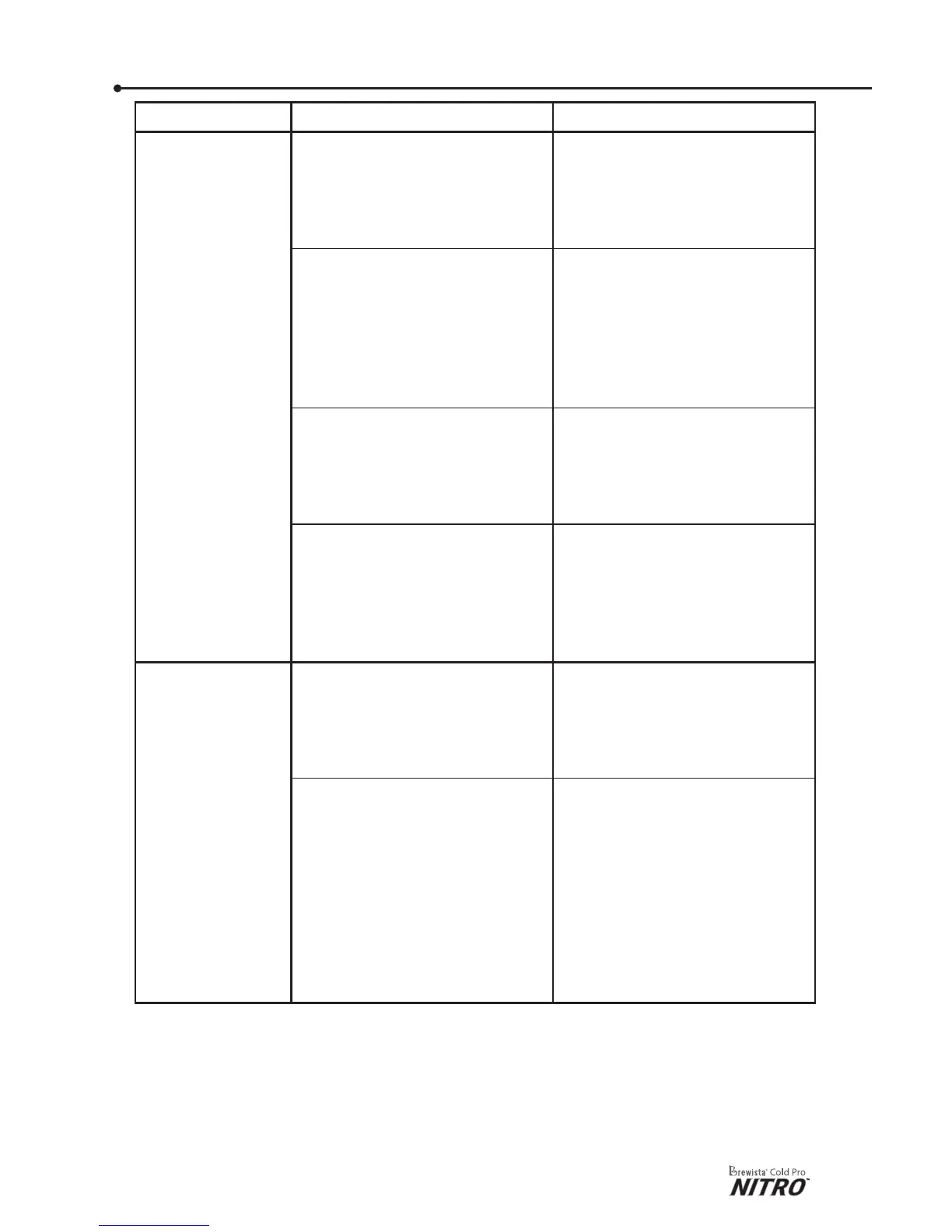

Troubleshoong your Cold Pro Nitro™ System

Problem Cause Soluon

Not enough or too

much foam

The gas needle valve is not set up

properly.

Follow instrucons in the

“Changing the Gas Level” secon

on page 7. The needle valve has

a default setup of 1 mm with a

tolerance of +/- 0.25

The owrate of the coee and

the gas have to be adjusted to

coordinate together. If a change

of owrate occurs through

change of the owrate disc (9 or

10), the gas owrate has to be

re-adjusted.

Follow instrucons in the

“Changing the Gas Level” secon

on page 7. The needle valve has

a default setup of 1 mm with a

tolerance of +/- 0.25

A change in the foaming behavior

can also be aected through

a owrate reducon due to

clogging of the lter adapter (19)

or the tap jet-nozzle (3).

Check all lters or strainers

and remove any parcles in it.

Unscrew the tap nozzle (3) and

check for parcles lodged in the

strainer (8).

If there is too much foam sud-

denly, the dispenser might suck

air in via the product intake line

(11).

Check if all connecons

between the dispenser and

coee container are sealed

well. Somemes the push-in

connecon system causes air

leaks that need to be removed.

Dispensed coee

is not cold enough

No electrical power or

temperature control (5) is turned

o.

Check the dispenser’s electrical

connecon.For maximum

cooling, turn the temperature

control (5) clockwise to the 7

o’clock posion.

The temperature can be adjusted

on the temperature control (5)

on the front panel. The target

dispense temperature at max

setup is 41° F (5° C) (+/- 1.8° F

or 1° C) to 62° F (17° C). In case

of heavy tapping operaon or a

warm coee input temperature,

this temperature might not be

achieved.

If the cooling capacity of the

device is not strong enough, you

will need to increase the cooling

capacity.

Possible soluons for this are

described a the top of page 8.

Loading...

Loading...