30 BRIGGSandSTRATTON.COM

Inspection

1. Clean gummy or dirty fuel tanks with Briggs & Stratton

Carburetor Cleaner #100041 or #100042, or equivalent.

2. Inspect fuel tank for:

• Corrosion

• Leaks

• Broken mounting brackets

3. Check fuel cap and filler neck for:

• Proper seals

• Vents

• Functional quantity gauge (if equipped)

4. Check fuel filter for blockage of any kind.

5. Check fuel shut off valve for proper operation.

Clean or replace parts as required. Fuel filter replacement

is recommended annually or any time the fuel system is

serviced.

Installation

1. Install tank support to tank. Slip fuel hose under

governor link and spark plug wire through hole in

support as tank is installed. Torque screws to values

listed in Engine Specifications.

2. Assemble shut-off valve and fuel filter, if equipped, to

fuel hose.

3. Install hose assembly to tank fitting and carburetor

fitting with new clamps.

4. Install control panel/trim plate. Torque screws to

values listed in Engine Specifications.

5. Add small amount of fuel to tank, open shut off valve,

and check for leaks. Repair as necessary.

6. Install air cleaner assembly.

7. Start engine and check for leaks. Repair as necessary.

Carburetor Service

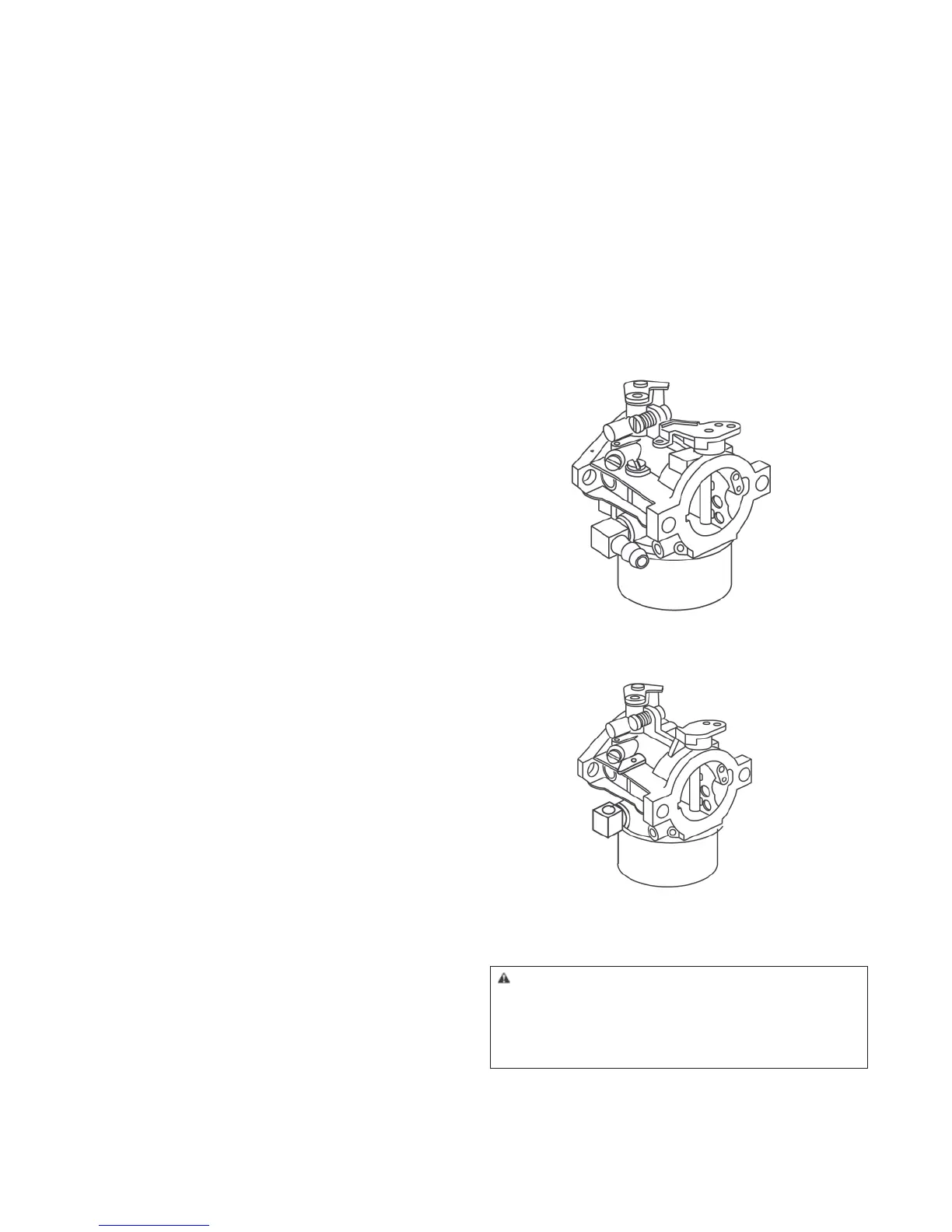

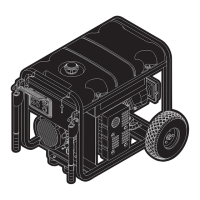

LMT Carburetor

Two versions of this carburetor have been used (Figures 25

and 26).

These carburetors have a fi xed high speed main jet with a

screw for idle mixture and idle speed adjustment. The letters

LMT are cast into the body of the carburetor while the iden-

tifi cation numbers are stamped into the carburetor mounting

fl ange next to the idle mixture screw or above the fuel inlet.

Figure 25

Figure 26

WARNING Before servicing the carburetor or other fuel

system components, drain all fuel from the tank and turn

OFF the fuel valve (if equipped).

DO NOT attempt to stop the fuel flow by plugging the fuel

hose.

Loading...

Loading...