WARNING: Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

16. Replace main furnace door.

VI. SERVICING HOT SURFACE IGNITOR

The ignitor does NOT require annual inspection. Check ignitor

resistance before removal.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect ignitor wire connection.

4. Check ignitor resistance.

a. Using an ohm meter, check resistance across both ignitor

leads in connector.

b. Cold reading should be between 45 ohms and 90 ohms.

c. If ohm reading is higher than 110 ohms, ignitor is

cracked and must be replaced.

5. Remove ignitor.

a. While spreading ignitor bracket legs outward, use hand

to GENTLY guide ignitor out of burner box.

CAUTION: The ignitor is fragile. DO NOT allow it to

hit the side of the burner box opening while removing or

replacing it.

b. Inspect ignitor for a white area indicating a crack may be

present. If found, replace ignitor.

NOTE: A small crack cannot be seen on a new ignitor. After a

period of operation, a white area will be visible around the crack.

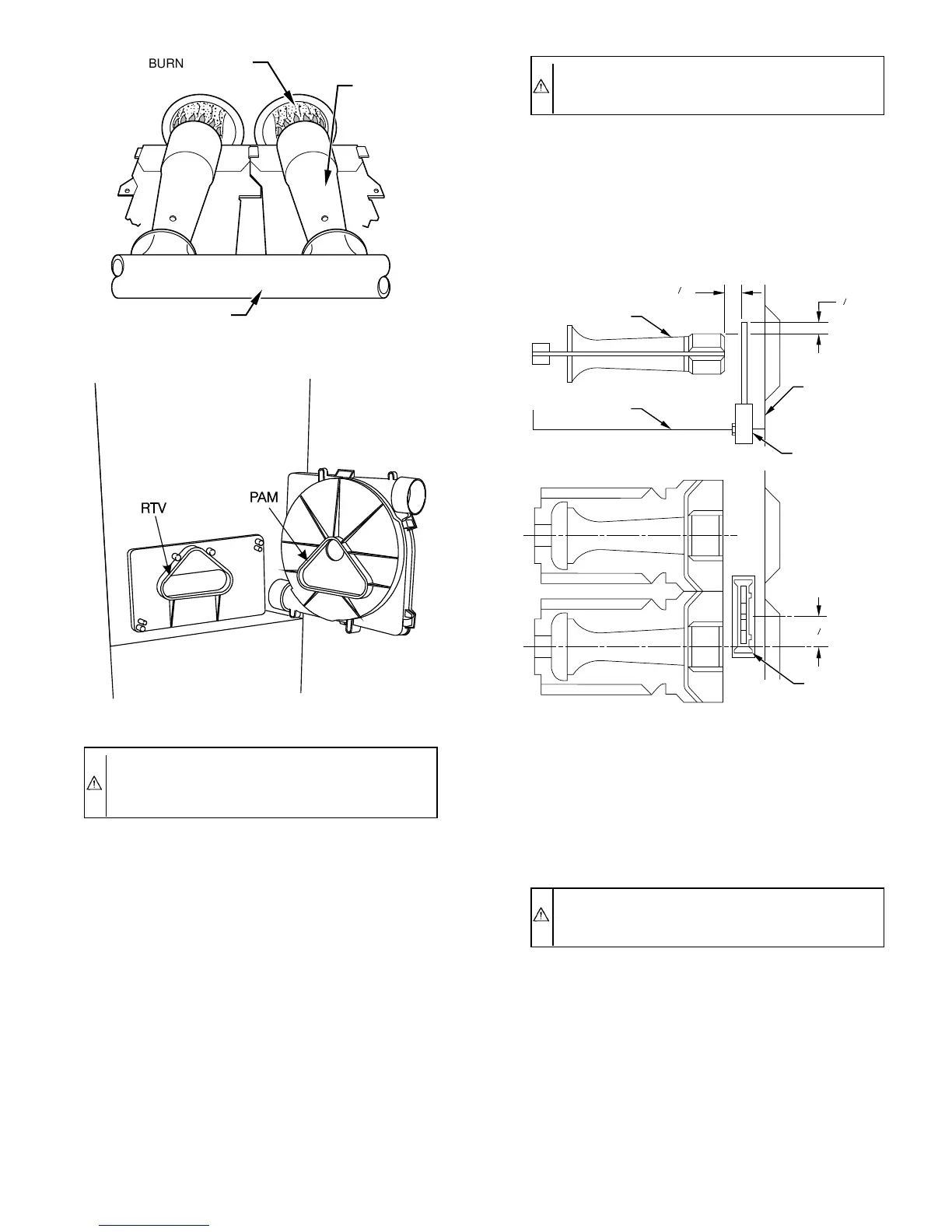

6. After inspecting or replacing ignitor, install it into burner

box by gently pushing ignitor into bracket until bracket legs

fully secure ignitor. (See Fig 11.)

7. Connect ignitor wire connection.

8. Turn on gas and electrical supplies to furnace.

9. Check furnace operation through 2 heat operating cycles.

10. Replace main furnace door.

VII. ELECTRICAL CONTROLS AND WIRING

CAUTION: There may be more than 1 electrical supply

to the unit. Check accessories and cooling unit for

additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 12 for field wiring information

and to Fig. 17 for unit wiring information.

NOTE: If the polarity is not correct, the STATUS LED on the

control center will flash rapidly and prevent the furnace from

operating. The control system also requires an earth ground for

proper operation of the control center and flame sensing.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the control center. (See Fig. 13.) Any direct shorts of the 24-v

wiring during installation, service, or maintenance will cause this

fuse to blow. If fuse replacement is required, use ONLY a fuse of

identical size.

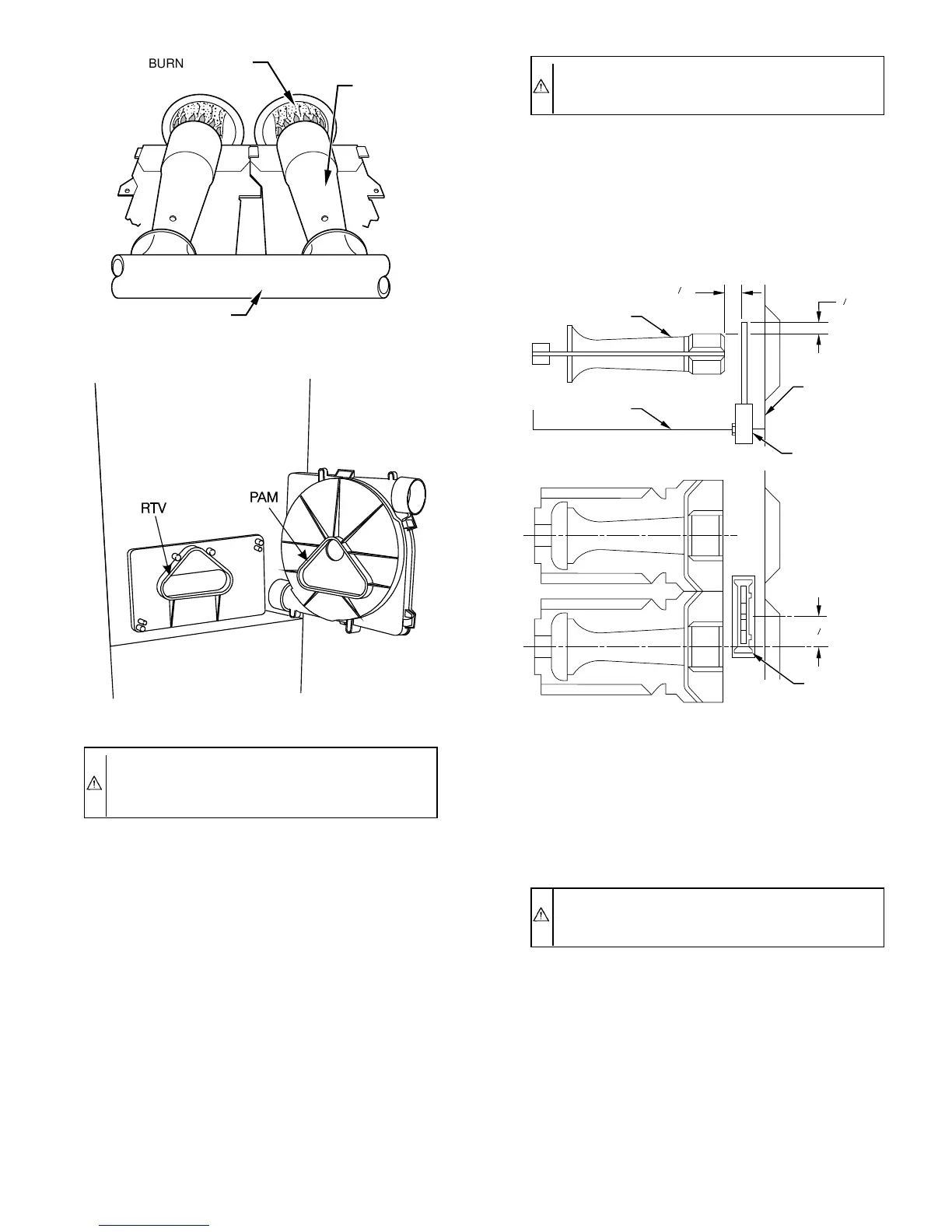

Fig. 9—Burner Flame

A89020

BURNER FLAME

BURNER

MANIFOLD

Fig. 10—Gasket on Collector Box

A93081

Fig. 11—Hot Surface Ignitor Location and Burner

Assembly

A93260

BURNER

IGNITOR

13

32

"

11

32

"

7

8

"

C

L

C

L

IGNITOR

ASSEMBLY

IGNITOR

ASSEMBLY

CELL

PANEL

BURNER

BURNER BOX

—7—

Loading...

Loading...