17

Heating

When the thermostat initiates a call for First Stage Heating by

closing its W1 contacts, a 24-v signal is conveyed to the CTB’s

TSTAT terminal strip at W1. An internal path passes this signal to

connector DDC/TSTAT pin 5. A harness wire carries this signal to

Fan Speed Relay board pin J1-2. Relay K1 is energized. The relay

board’s output to VFD at pin J2-3 is energized, providing a

24VDC signal to VFD terminal 15. The VFD starts the indoor fan

motor, runs at 60 Hz for full/high speed operation.

When space temperature rises to satisfy the thermostat W1 de-

mand, contact W1 opens de-energizing terminal W1. Relay K1 is

de-energized. The relay board output at J2-3 to the VFD is re-

moved.

524J, 548J/549J/551J/558J SERIES

Indoor fan motor ramps down to stop.

580J/581J SERIES

The IGC’s fan-off delay sequence will energize relay K3 for

45-seconds, causing the VFD to operate the indoor fan motor

at 40 Hz (low speed) for 45-seconds, then indoor fan motor

will ramp down to stop.

Operating Fan for Test and Balance

During the Test and Balance procedure, it is necessary to operate

the supply fan in High Speed without concurrent operation of the

Cooling or Heating systems. Use the following procedure to force

the fan speed to High.

UNITS WITHOUT ACCESSORY KEYPAD

1. Set the space thermostat to SYSTEM OFF and FAN in

AUTO.

2. Disconnect unit power. Lock-out/tag out.

3. Open the fan access panel and locate the VFD (see

Fig. 6-23 for your specific unit).

4. Locate and connect the WHT and YEL wires extending

from the VFD. The two wires are bundled together using

the label shown in Fig. 24.

Fig. 24 — High Speed Test Label

5. Locate pressure ports or pitot tubes in the return duct and

supply duct to measure external static pressure. See

Fig. 25 for typical locations.

6. Restore unit power.

7. Set the space thermostat to FAN CONT.

8. Check the motor speed with stroboscope or similar tool.

Motor shaft speed must be in 1725 to 1760 rpm (28.8 to

29.3 r/s) range for High Speed.

9. Replace the fan access panel.

10. Perform test and balance procedure.

11. Adjust the supply fan speed according to base unit instruc-

tions to deliver the project selection cfm value. Ensure the

selection cfm value is not lower that the “Min cfm Per Fan

Motor Type” for this unit-size as found in Tables 2-9 on

page 4.

To restore the unit to ready-to-start condition, disconnect the

unit power and lock-out/tag-out, set the space thermostat to

FAN AUTO, remove the test pressure ports from the external duct

locations, and disconnect the WHT and YEL wires. Replace the

supply fan access panel. Restore unit power.

UNIT WITH ACCESSORY VFD KEYPAD

1. Set the space thermostat to SYSTEM OFF and FAN in

AUTO.

2. Disconnect unit power. Lock-out/tag-out.

3. Open the fan access panel (see Fig. 6-23 for specific unit).

4. Locate pressure ports or pitot tubes in the return duct and

supply duct to measure external static pressure. See

Fig. 25 for typical locations.

5. Restore unit power.

6. Set the space thermostat to FAN CONT.

7. At the VFD keypad, tap the HAND key and then tap the

UP arrow button to increase the motor speed until 60.0 is

displayed on the display screen.

8. Check the motor speed with stroboscope or similar tool.

Motor shaft speed must be in 1725 to 1760 rpm (28.8 to

29.3 r/s) range for High Speed.

9. Replace the fan access panel.

10. Perform Test and Balance procedure.

11. Adjust the supply fan speed according to base unit instruc-

tions to deliver the project selection cfm value. Ensure the

selection cfm value is not lower that the “Min cfm Per Fan

Motor Type” for this unit-size as found in Tables 2-9 on

page 4.

To restore the unit to ready-to-start condition, tap the DOWN ar-

row button to reduce motor speed until the 40.0 is displayed on the

display screen and then tap the AUTO key. Disconnect the unit

power and lock-out/tag-out, set the space thermostat to FAN

AUTO. Remove the test pressure ports from the external duct

locations. Restore unit power.

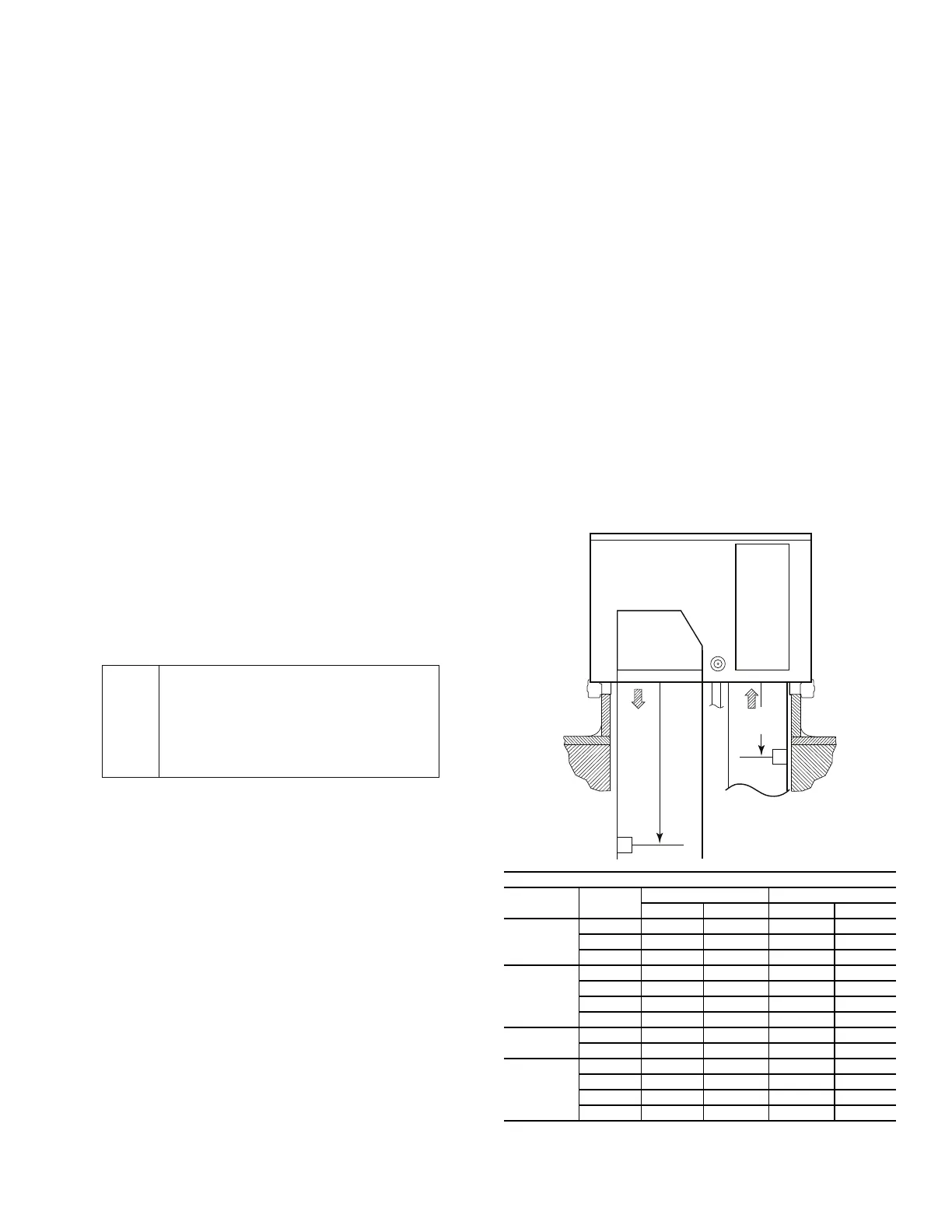

Fig. 25 — Measuring External Static Pressure — Distance

Below Unit Base

***

IMPORTANT

***

CONNECT WHITE & YELLOW WIRES

FOR HIGH SPEED BLOWER TEST

DISCONNECT FOR NORMAL OPERATION

48TM504557

SUPPLY

AIR

RETURN

AIR

A

B

AHRI PRESSURE LOCATIONS

MODEL SIZES

SUPPLY AIR [A] RETURN AIR [B]

in. mm in. mm

581J/551J

07-12 43.5 1100 12 310

14 64.5 1640 14 350

17-28 83 2110 19 490

580J/558J

07 32 830 10 260

08-14 43.5 1100 12 310

16 64.5 1640 14 350

17-30 83 2110 19 490

549J

07-09 43.5 1100 12 310

12 44.5 1130 13 330

548J

07 32 830 10 260

08-12 43.5 1100 12 310

14 44.5 1130 14 350

17-24 83 2110 19 490

Loading...

Loading...