3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a refrig-

erant leak.

c. Leak test all refrigerant tubing connections using elec-

tronic leak detector, halide torch, or liquid-soap solution.

If a refrigerant leak is detected, see the Check for

Refrigerant Leaks section.

d. Inspect all field- and factory-wiring connections. Be sure

that connections are completed and tight.

e. Ensure wires do not contact refrigerant tubing or sharp

sheet metal edges.

f. Inspect coil fins. If damaged during shipping and han-

dling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

CAUTION: Do not purge gas supply into the combus-

tion chamber. Do not use a match or other open flame to

check for gas leaks. Failure to follow this warning could

result in an explosion causing serious injury or death.

a. Make sure gas line is free of air. Before lighting the unit

for the first time, perform the following with the gas

valve in the ‘‘OFF’’ position:

If the gas supply pipe was not purged before

connecting the unit, it will be full of air. It is

recommended that the ground joint union be

loosened, and the supply line be allowed to

purge until the odor of gas is detected. Never

purge gas lines into a combustion chamber.

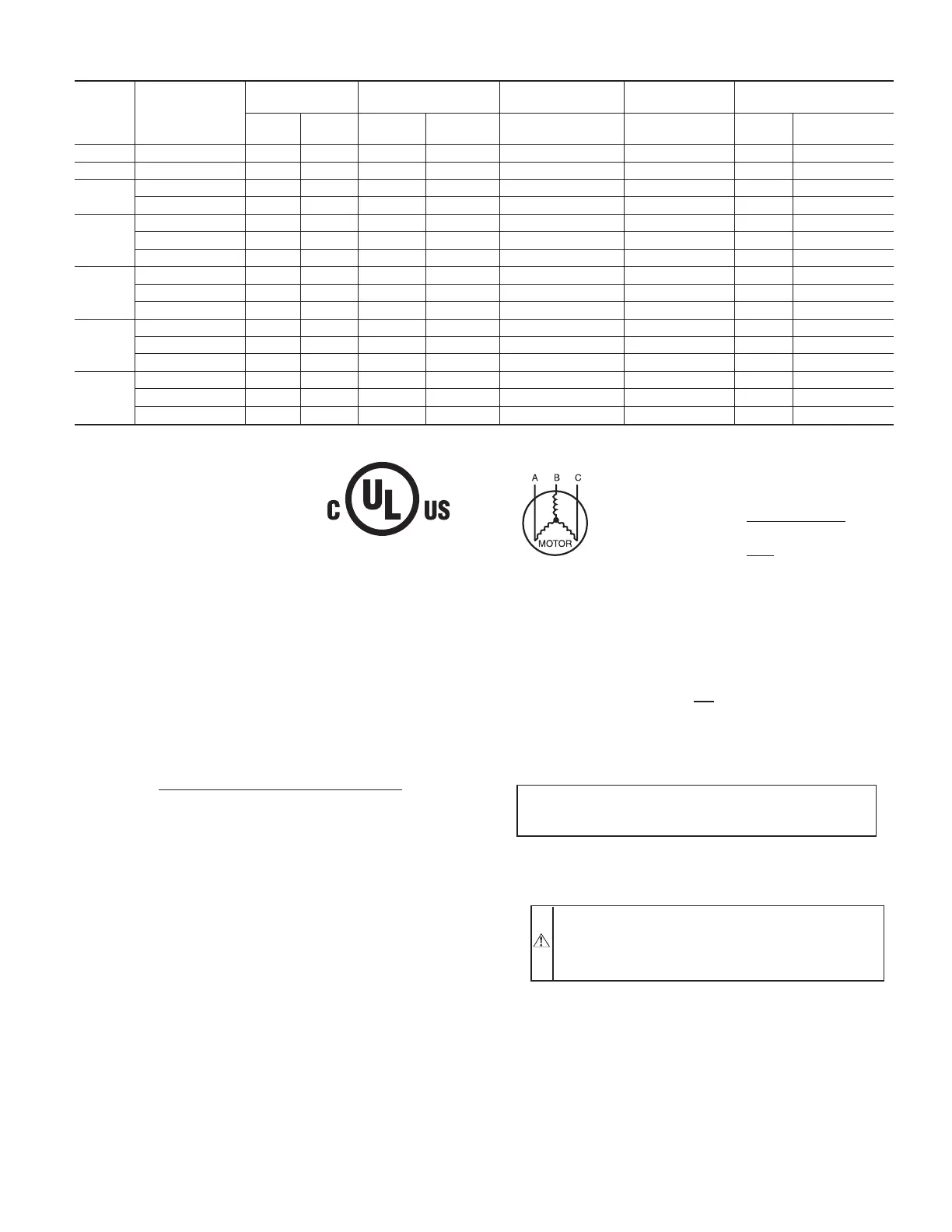

TABLE 4—ELECTRICAL DATA—UNIT 582A

UNIT

SIZE

582A

V-PH-HZ

VOLTAGE

RANGE

COMPRESSOR

OUTDOOR FAN

MOTOR

INDOOR FAN

MOTOR

POWER SUPPLY

Min Max RLA LRA FLA FLA MCA

Max Fuse or

Ckt Bkr

018 208/230–1–60 187 253 9.0 45.0 0.8 1.8 13.9 20

024 208/230–1–60 187 253 12.8 61.0 0.8 2.0 18.8 30

030

208/230–1–60 187 253 14.4 73.0 0.8 2.0 20.8 30

208/230–3–60 187 253 12.6 68.0 0.8 2.0 13.2 20

036

208/230–1–60 187 253 13.0 81.0 1.6 3.6 24.0 35

208/230–3–60 187 253 9.0 78.0 1.6 3.6 16.5 25

460–3–60 414 506 4.5 40.0 0.9 1.9 8.4 15

042

208/230–1–60 187 253 18.6 105.0 1.6 3.8 27.5 45

208/230–3–60 187 253 10.7 85.0 1.6 3.8 18.8 25

460–3–60 414 506 5.3 42.0 0.9 2.0 9.5 15

048

208/230–1–60 197 253 25.3 131.0 1.6 3.8 37.0 60

208/230–3–60 187 253 13.5 108.0 1.6 3.8 22.3 35

460–3–60 414 506 6.7 47.5 0.9 2.0 11.3 15

060

208/230–1–60 187 253 28.9 147.0 1.6 6.2 43.9 60

208/230–3–60 187 253 18.6 125.0 1.6 6.2 31.1 45

460–3–60 414 506 8.5 66.5 0.9 3.2 14.7 20

Table 4—Legend

C99024

452=5v

457=7v

455=2v

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. Canadian units may be

fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%.

Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

max voltage deviation from average voltage

= 100 x

average voltage

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

452 + 464 + 455

Average Voltage =

3

1371

=

3

= 457

Determine maximum deviation from average voltage.

(AB) 457

(BC) 464

(AC) 457

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

7

% Voltage Imbalance = 100 x

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

®

CKT BKR

—

Circuit Breaker

—13—

Loading...

Loading...