36

Thermostats

A single stage heating and cooling thermostat can be used with the

furnace. The furnace control board CPU will control the furnace

and outdoor unit staging. A two stage heating and cooling

thermostat can also be used to control the staging. For two stage

thermostat control of the furnace staging, turn SW1-LHT ON at the

furnace control board. For two stage thermostat control of a 2-stage

outdoor unit, remove the ACRDJ jumper from the furnace control

board. Refer to typical thermostat wiring diagrams and the

Sequence of Operation section for additional details. Consult the

thermostat installation instructions for specific information about

configuring the thermostat. See Fig. 36 and 37.

Accessories (See Fig. 34 and 36.)

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used) using

1/4--in. female quick connect terminals to the two male

1/4--in. quick--connect terminals on the control board

marked EAC--1 and EAC--2. The terminals are rated for

115VAC, 1.0 amps maximum and are energized during

blower motor operation.

2. Humidifier (HUM)

The HUM terminal is a 24 VAC output, energized when the gas

valve relay is operating during a call for heat.

Connect an accessory 24 VAC, 0.5 amp. maximum humidifier (if

used) to the ¼--in. male quick--connect HUM terminal and

COM--24V screw terminal on the control board thermostat strip.

NOTE: If the humidifier has its own 24 VAC power supply, an

isolation relay may be required. Connect the 24 VAC coil of the

isolation relay to the HUM and COM/24V screw terminal on the

control board thermostat strip. See Fig. 34.

Alternate Power Supplies

This furnace is designed to operate on utility generated power

which has a smooth sinusoidal waveform. If the furnace is to be

operated on a generator or other alternate power supply, the

alternate power supply must produce a smooth sinusoidal

waveform for compatibility with the furnace electronics. The

alternate power supply must generate the same voltage, phase, and

frequency (Hz) as shown in Table 11 or the furnace rating plate.

Power from an alternate power supply that is non-sinusoidal may

damage the furnace electronics or cause erratic operation.

Contact the alternate power supply manufacturer for specifications

and details.

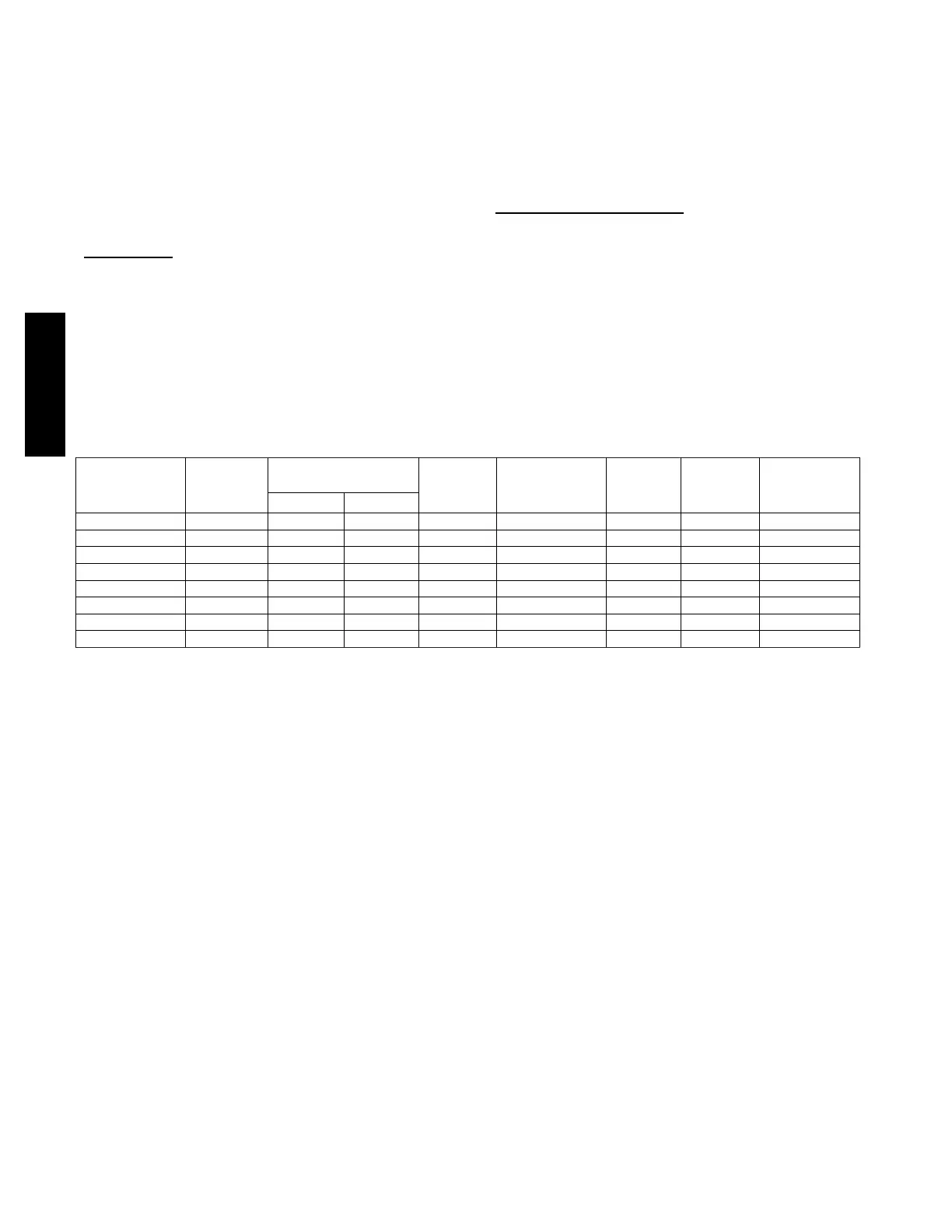

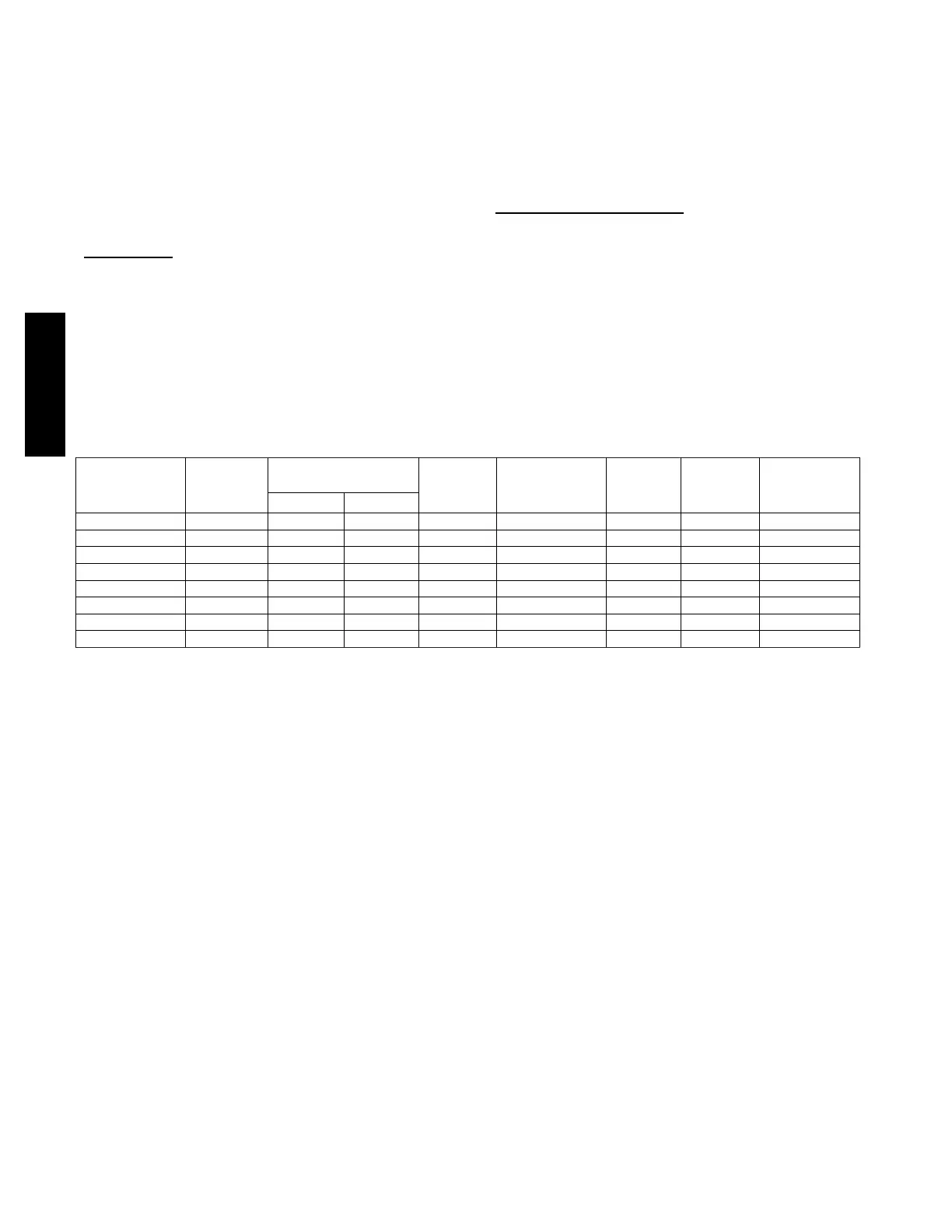

Table 11 – Electrical Data

UNIT SIZE

V O LT S ---

H E R T Z ---

PHASE

OPERATING VOLTAGE

RANGE*

MAXIMUM

UNIT

AMPS

UNIT

AMPACITY#

MINIMUM

WIRE

SIZE

AWG

MAXIMUM

WIRE

LENGTH

FT (M)}

MAXIMUM

FUSE OR CKT

BKR

AMPS{

Maximum* Minimum*

30040 1 1 5 --- 6 0 --- 1 127 104 7.5 10.3 14 36 (11.0) 15

36040 1 1 5 --- 6 0 --- 1 127 104 7.5 10.3 14 36 (11.0) 15

36060 1 1 5 --- 6 0 --- 1 127 104 7.6 10.4 14 35 (10.7) 15

42060 1 1 5 --- 6 0 --- 1 127 104 10.7 14.3 14 26 (7.9) 15

48080 1 1 5 --- 6 0 --- 1 127 104 10.1 13.5 14 27 (8.2) 15

60080 1 1 5 --- 6 0 --- 1 127 104 13.1 17.3 12 33 (10.1) 20

60100 1 1 5 --- 6 0 --- 1 127 104 13.5 17.7 12 32 (9.8) 20

66120 1 1 5 --- 6 0 --- 1 127 104 12.0 15.9 12 36 (11.0) 20

* Permissible limits of the voltage range at which the unit operates satisfactorily.

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier,

etc.) ful l load amps.

{Time---delay type is recommended.

}Length shown is as measured one way along wire path between furnace and service panel for maximum 2 percent voltage drop.

925TA

Loading...

Loading...