67

Checklist

1. Put away tools and instruments. Clean up debris.

2. Verify that the jumper is removed from the TEST/TWIN

terminal. Verify that there is nothing plugged into the PLT

connector. (Note: If there is a jumper connector plugged

into PLT, remove it and discard.) See Fig. 36.

3. Verify that Heating Operating Mode switch SW-1 is set

properly. See Fig. 36.

4. Verify that the Blower/Heat Off Delay SW-2 and SW-3

switches are set as desired. See Fig. 36.

5. Verify that the blower (lower door in upflow position) and

control (“Main” or upper door in upflow position) doors are

properly installed.

6. Verify that the Status LED glows. If not, check that the

power supply is energized and that the blower door is

secure. See Fig. 60 to interpret diagnostic codes.

7. Cycle test furnace with room thermostat to be sure that it

operates properly with the room thermostat. Check all

modes including Heat, Cool and Fan.

8. Check operation of accessories per manufacturer’s

instructions.

9. Review Owner’s Manual with owner.

10. Attach entire literature packet to furnace.

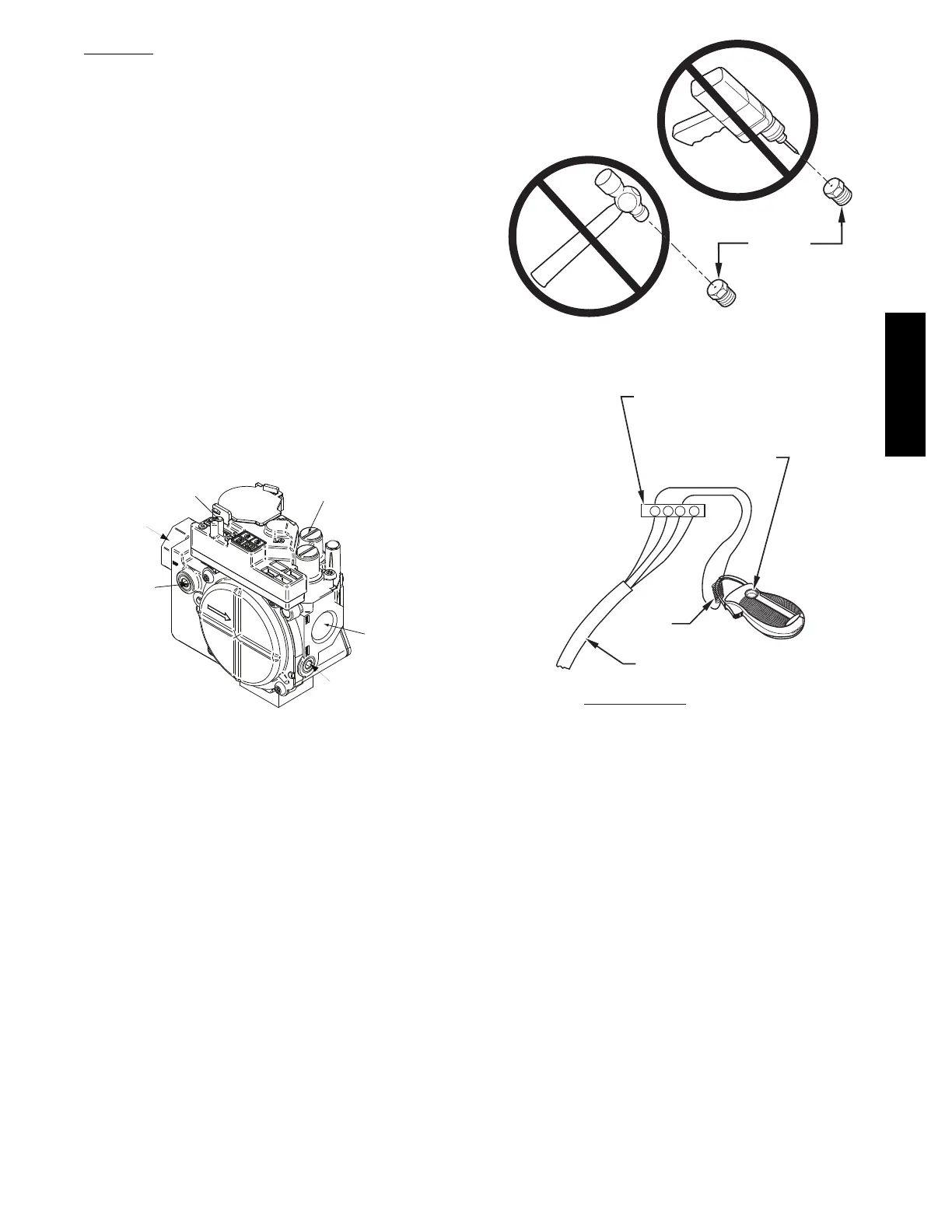

ON/OFF Switch

Regulator Seal Cap

Regulator Adjustment

Regulator Seal Cap

under Cap

1/2” NPT Outlet

1/8” NPT Manifold

Pressure Tap

1/8” NPT Inlet

Pressure Tap

1/2” NPT Inlet

TWO-STAGE

A11152

Fig. 57 -- Gas Valve

BURNER

ORIFICE

A93059

Fig. 58 -- Orifice Hole

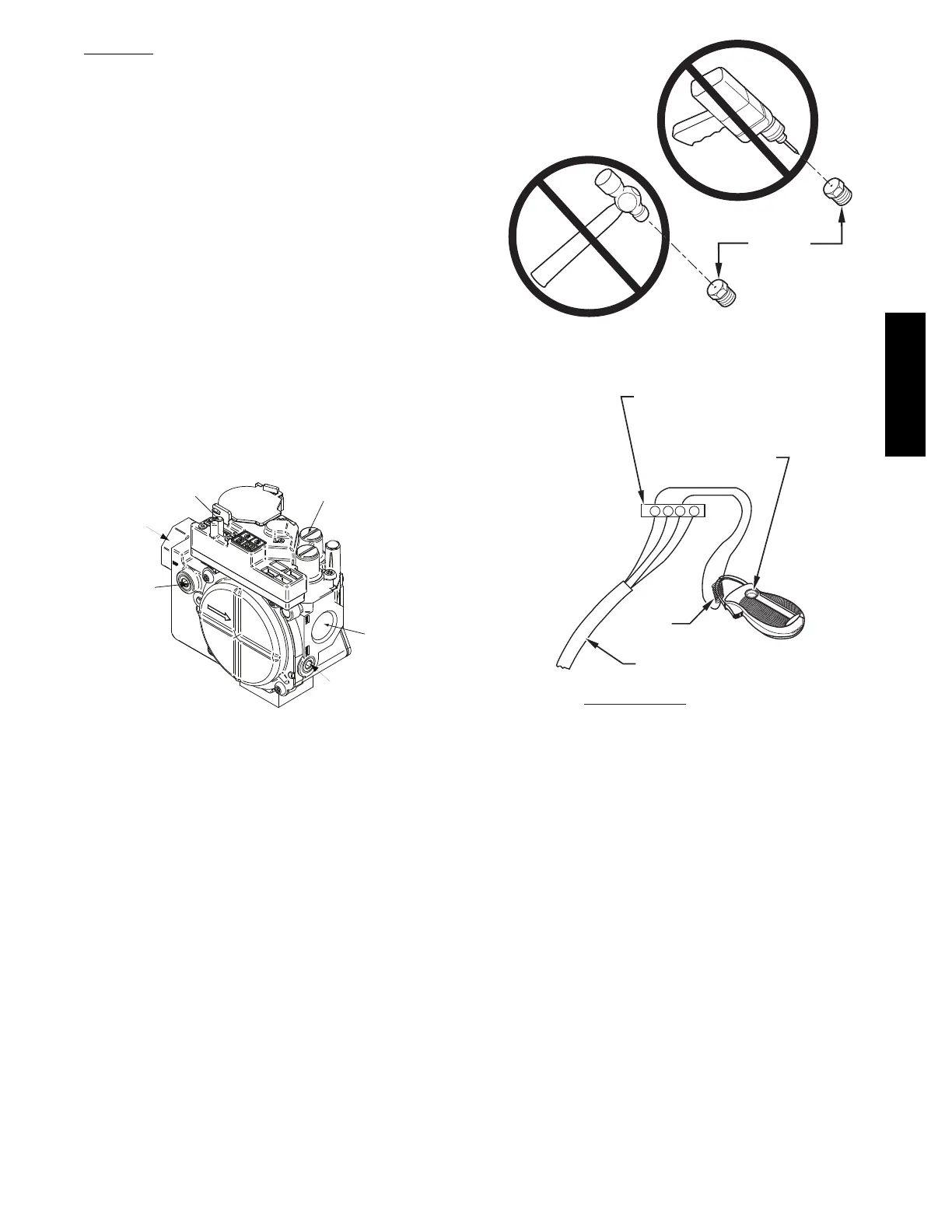

R Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

=

0.5 AMPS FOR THERMOSTAT

ANTICIPATOR SETTING

FROM UNIT 24-V

CONTROL TERMINALS

A96316

Fig. 59 -- Amp. Draw Check with Ammeter

925TA

Loading...

Loading...