987MB: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

55

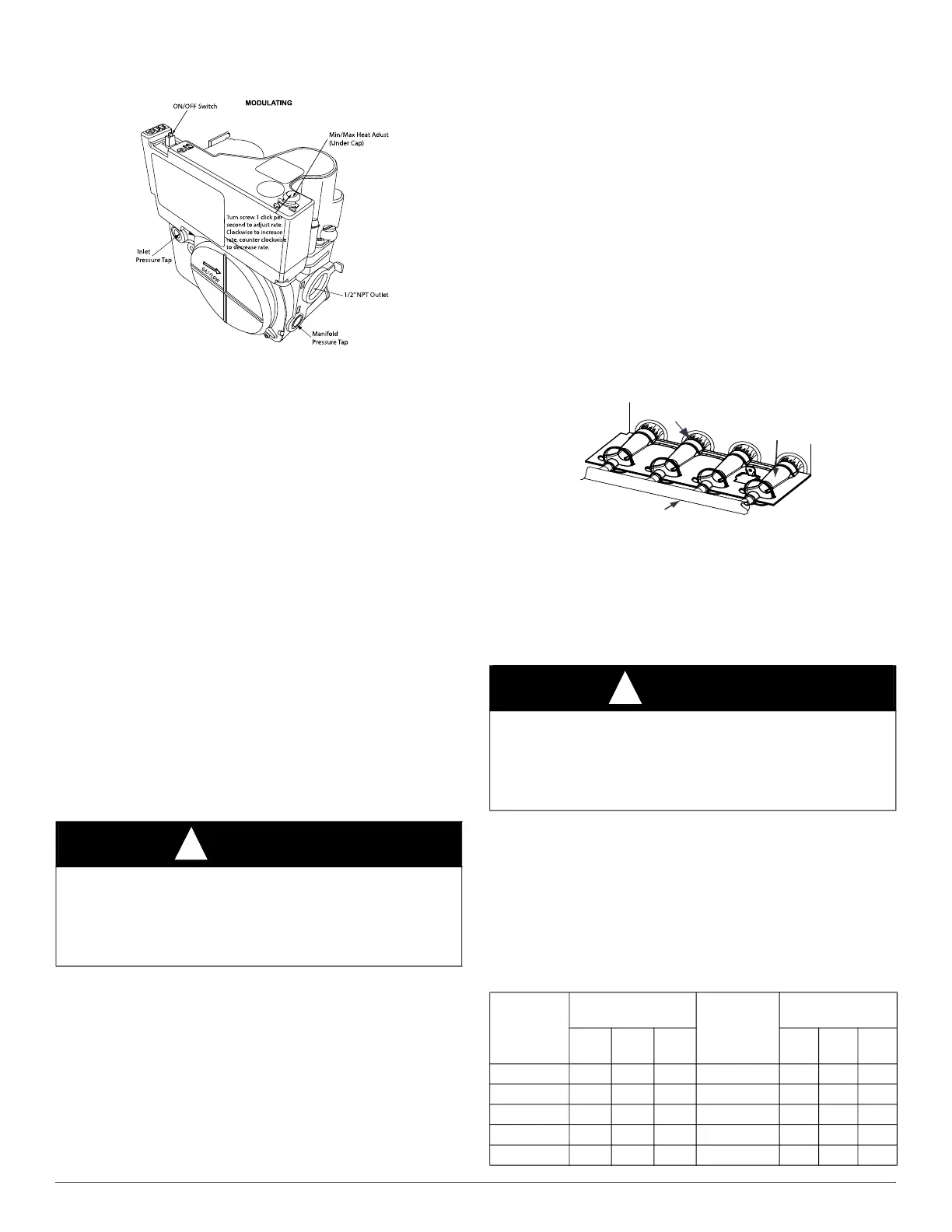

than one click per second until you obtain the required manifold

pressure, see Fig. 64.

A10496

Fig. 64 – Gas Valve without Tower Pressure Ports

10. Main burner flame should be clear blue, almost transparent.

11. After adjusting the Maximum Heat manifold pressure, remove

jumpers across thermostat connections to terminate the call for

heat.

12. Wait for blower off-delay to finish then reset 115-v power to

furnace.

Adjust Manifold Pressure - Minimum Heat

To adjust manifold pressure to obtain input rate for Minimum Heat:

1. Turn SW1-2 ON and SW4-2 must be OFF.

2. Jumper R and W/W1 thermostat connections on control to start

furnace.

3. After the main burners ignite and the blower starts, confirm

Minimum Heat manifold pressure is correct, based on the manifold

pressure tables in the installation instructions.

4. To adjust the Minimum Heat manifold pressure, slowly turn

adjusting screw counterclockwise to decrease manifold pressure or

clockwise to increase manifold pressure. Turn adjustment no more

than one click per second until you obtain the required manifold

pressure, see Fig. 64.

5. After adjusting the manifold pressure, remove jumpers across

thermostat connections to terminate the call for heat. Wait until the

blower off delay is completed.

6. Move setup switch SW1-2 to the OFF position.

Clocking The Meter

Verify natural gas input rate by clocking meter.

NOTE: Contact your HVAC distributor or gas supplier for metric gas

meter Tables, if required.

1. Turn off all other gas appliances and pilots served by the meter.

2. Move setup switches SW1-2 to ON position and SW4-2 to OFF.

This keeps furnace locked in low--heat operation when only W/W1

is energized or high heat operation when R to W/W1 and W2 are

jumpered.

3. Jumper R to W/W1 and W2. Run furnace for 3 minutes in

maximum heat operation.

4. Measure time (in sec) for gas meter to complete one revolution and

note reading. The 2 or 5 cubic feet dial provides a more accurate

measurement of gas flow.

5. Refer to Table 17 for cubic ft. of gas per hr. Multiply gas rate cu

ft./hr by heating value (BTUh/cu ft.) to obtain input rate.

6. If clocked rate does not match required input from Step 5, increase

manifold pressure to increase input or decrease manifold pressure

to decrease input. Repeat steps 3 through 5 until correct maximum

heat input is achieved. See Fig. 59.

NOTE: Setup switches SW1-2 must be ON and SW4-2 must be OFF.

This keeps furnace locked in minimum heat operation when R to W/W1

is energized. Repeat items 3 through 6 for minimum heat operation until

minimum heat input is achieved.

7. Remove jumpers across thermostat connections to terminate the

call for heat. Wait until the blower off delay is completed then reset

115-v power to furnace.

8. Restore furnace to normal operating condition.

A11461

Fig. 65 – Burner Flame

9. Remove jumpers across thermostat connections to terminate the

call for heat. Wait until the blower off delay is completed.

10. Disconnect 115 VAC power to furnace.

11. Turn gas valve ON/OFF switch to OFF.

12. Remove water column manometer or similar device from manifold

pressure tap.

13. Tighten set screw on manifold tower pressure tap with 3/32-in hex

wrench, or if 1/8-in. NPT plug was removed, apply pipe dope

sparingly to end of plug and reinstall in the gas valve.

14. Turn gas valve ON/OFF switch to ON.

15. Move setup SW1-2 on furnace control to position required for

attached thermostat (OFF for single-stage thermostats, ON for

two-stage thermostats).

16. Check for gas leaks and verify furnace operation.

.

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Manifold pressure tap set screw must be tightened and ⅛-in. NPT pipe

plug must be installed to prevent gas leaks.

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Manifold pressure tap set screw must be tightened or ⅛-in. NPT pipe

plug must be installed to prevent gas leaks.

Table 17 – Gas Rate (CU ft./hr)

SECONDS

FOR 1 REV

SIZE OF TEST DIAL

SECONDS

FOR 1 REV

SIZE OF TEST

DIAL

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

10

360 720 1800 50 72 144 360

11

327 655 1636 51 71 141 355

12

300 600 1500 52 69 138 346

13

277 555 1385 53 68 136 340

14

257 514 1286 54 67 133 333

Burner Flame

Burner

Manifold

Loading...

Loading...