Residential Air Conditioners and Heat Pumps Using R-22 and Puron® Refrigerant: Application Guideline and Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

32

12. Sweat inlet of TXV, marked “IN” to liquid line. Avoid excessive

heat which could damage valve.

13. Install vapor elbow with equalizer adapter to vapor line of line set

and vapor connection to indoor coil. Adapter has a 1/4-in. male

connector for attaching equalizer tube.

14. Connect equalizer tube of TXV to 1/4-in. equalizer fitting on vapor

line adapter. Use backup wrench to prevent damage to equalizer

fitting.

15. Proceed with remainder of unit installation.

Replacing TXV on Indoor Coil (post-2006)

1. Pump system down to 2 psig and recover refrigerant.

2. Remove coil access panel and fitting panel from front of cabinet.

3. Remove TXV support clamp using a 5/16-in. nut driver. Save the

clamp (N coils only).

4. Remove TXV using a backup wrench on connections to prevent

damage to tubing.

5. Remove equalizer tube from suction line of coil.

Note: Some coils may have a mechanical connection. If coil has a

braze connection, use file or tubing cutter to cut brazed equalizer

line approximately 2 inches above suction tube.

6. Remove bulb from vapor tube inside cabinet.

7. Install the new TXV using a wrench and backup wrench to avoid

damage to tubing or valve to attach TXV to distributor.

8. Reinstall TXV support clamp (removed in item 3). (N coils only.)

9. Attach equalizer tube to suction line. If coil has mechanical

connection, then use wrench and back up wrench to attach. If coil

has brazed connection, use file or tubing cutters to remove

mechanical flare nut from equalizer line. Then use coupling to

braze the equalizer line to stub (previous equalizer line) in suction

line.

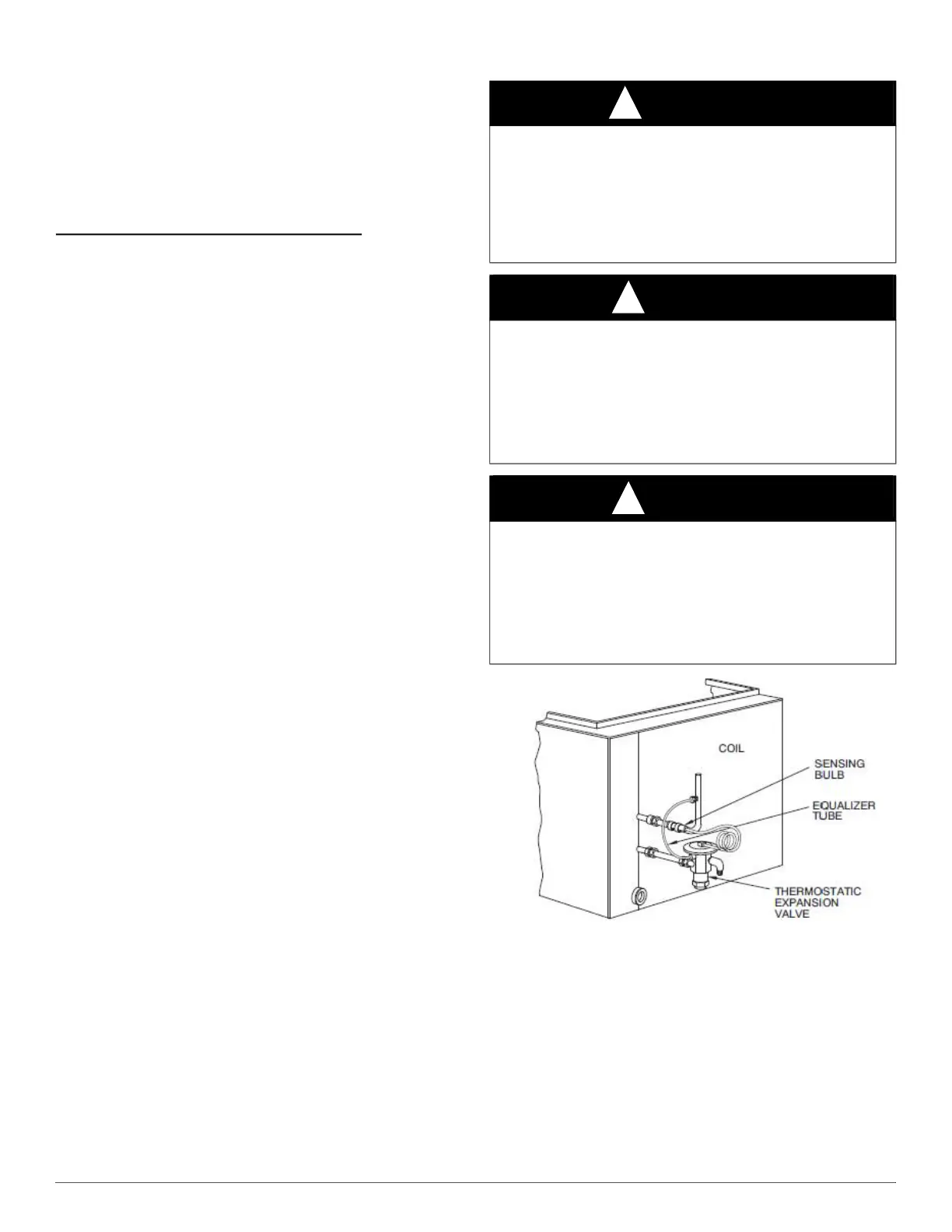

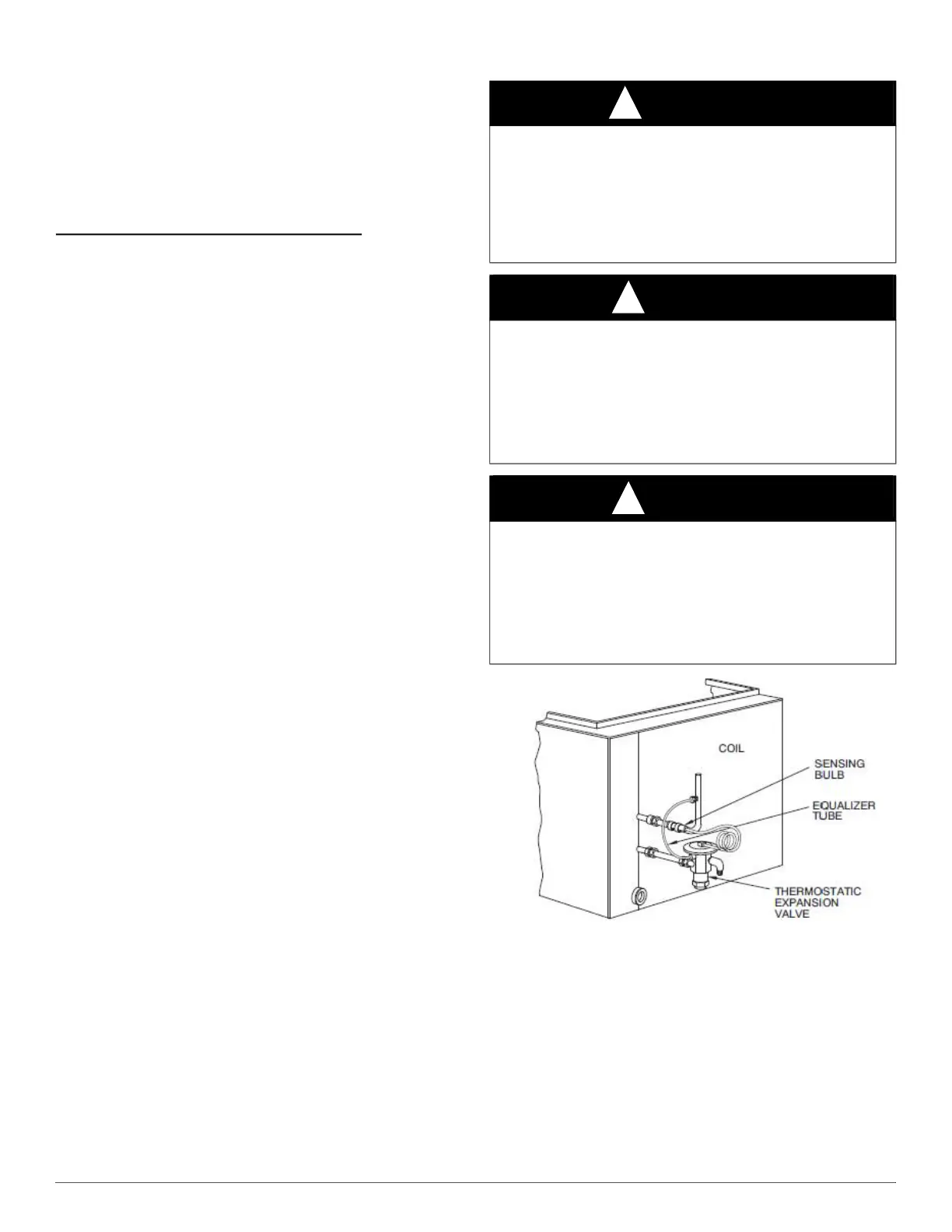

10. Attach TXV bulb to vapor tube inside cabinet, in same location as

original was when removed, using supplied bulb clamps (nylon or

copper). See Fig. 27 for correct positioning of sensing bulb.

11. Route equalizer tube through suction connection opening (large

hole) in fitting panel and install fitting panel in place.

12. Sweat inlet of TXV, marked “IN” to liquid line. Avoid excessive

heat which could damage valve.

13. Proceed with remainder of unit installation.

Make Piping Connections

A91277

Fig. 28 – Typical TXV Installation

WARNING

!

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal injury or death.

Relieve pressure and recover all refrigerant before system repair or

final unit disposal.

Use all service ports and open all flow-control devices, including

solenoid valves.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not leave system open to atmosphere any longer than minimum

required for installation. POE oil in compressor is extremely

susceptible to moisture absorption. Always keep ends of tubing sealed

during installation.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

If ANY refrigerant tubing is buried, provide a 6 in. vertical rise at

service valve. Refrigerant tubing lengths up to 36 in. may be buried

without further special consideration. Do not bury lines longer than 36

in.

Loading...

Loading...