12

In some applications, depending on space and convenience re-

quirements, it may be desirable to install 2 filter driers and

sight glasses in a single circuit application. One filter drier and

sight glass may be installed at A locations (see Fig. 9) or 2 fil-

ter driers and sight glasses may be installed at B locations (see

Fig. 9 and 10).

Select the filter drier for maximum unit capacity and minimum

pressure drop. Complete the refrigerant piping from the indoor

unit to the outdoor unit before opening the liquid and suction

lines at the outdoor unit.

INSTALL LIQUID LINE SOLENOID VALVE

It is recommended that a solenoid valve be placed in the main

liquid line (see Fig. 9 and 10) between the condensing unit and

the evaporator coil. Locate the solenoid valve at the outlet end

of the liquid line, near the evaporator coil connections, with

flow direction arrow pointed at the evaporator coil. Refer to

Table 13. (A liquid line solenoid valve is required when the liq-

uid line length exceeds 75 ft [23 m].) This valve prevents re-

frigerant migration (which causes oil dilution) to the compres-

sor during the off cycle, at low outdoor ambient temperatures.

Wire the solenoid in parallel with the compressor contactor coil

(see Fig. 9 and 10). This means of electrical control is referred

to as solenoid drop control.

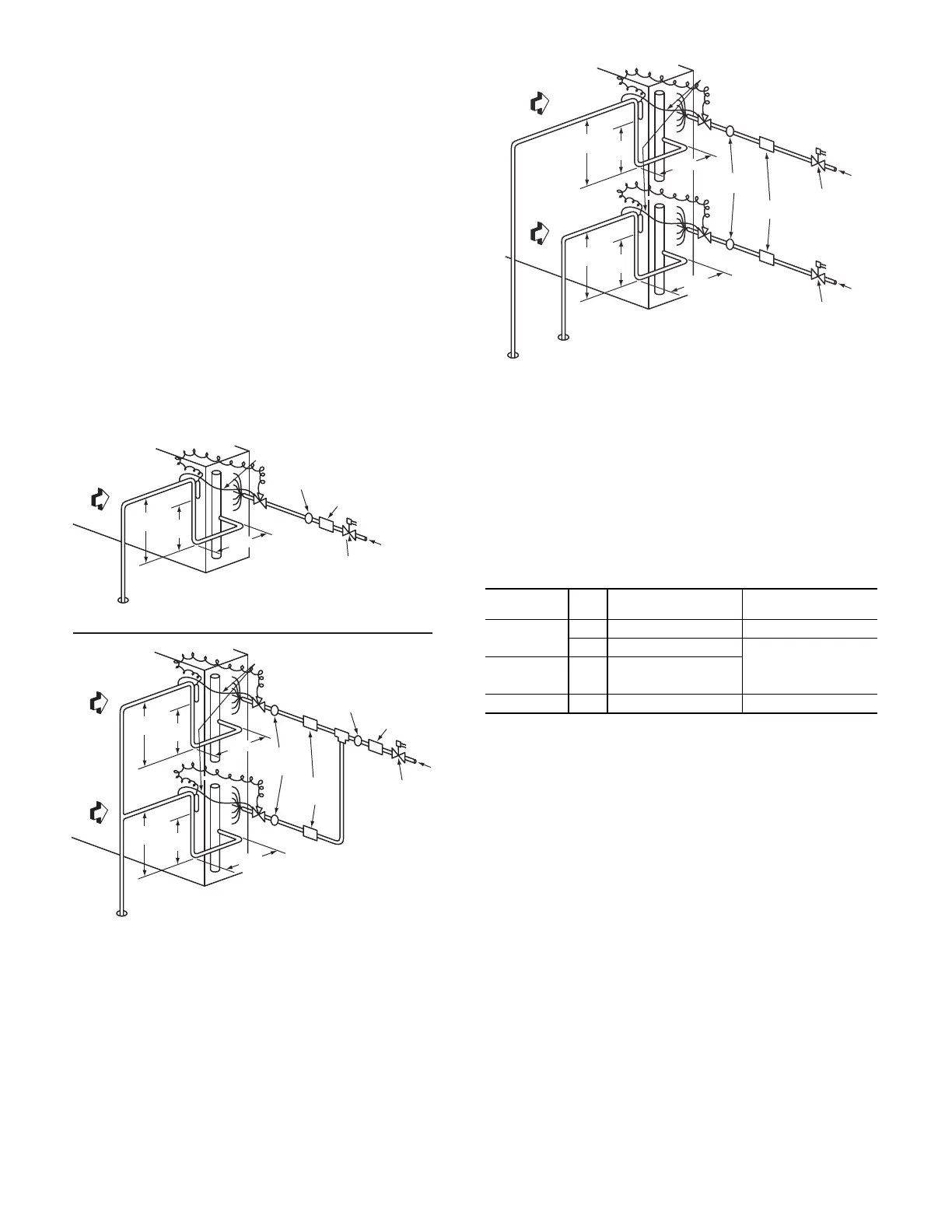

Fig. 9 — Location of Sight Glass(es) and Filter Driers

Typical 569J***A/B/G/H Systems

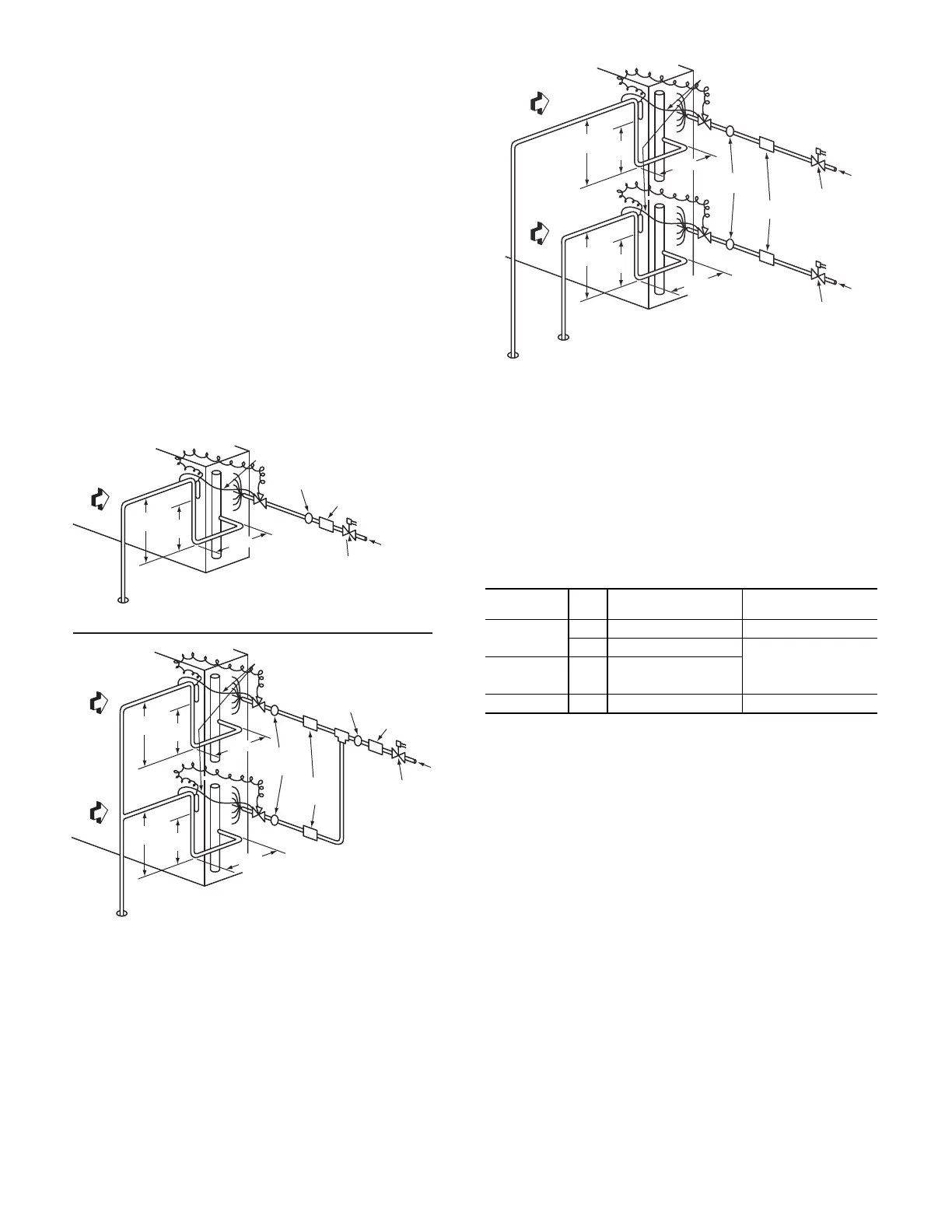

Fig. 10 — Location of Sight Glasses and Filter Driers

Typical 569J***D/E/F Systems

Solenoid Drop Control Wiring

Control the power to the liquid line solenoid through a Sole-

noid Valve Relay (SVR) in all units. Use part number

HN61PC005 (field-supplied, installed). 569J***A/B/G/H unit

requires one SVR; 569J***D/E/F unit requires two relays.

A unit with two liquid line solenoid valves also requires a sep-

arate control power transformer for the liquid solenoid valve

loads. Select TRAN3 transformer part number according to

unit power supply.

LEGEND

* Install as SVR-2 (SVR-1 is factory-installed).

Mount the SVR (and transformer TRAN3 when used) in unit

control box. Connect per wiring schematic label on unit.

NOTE: TRAN3 is provided with the HGBP factory installed op-

tion for 569J*12F units.

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

SIGHT

GLASSES

B LOCATION

TXV

CKT 2

FILTER DRIER

A LOCATION

FILTER

DRIERS

B LOCATION

FLO

W

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

SINGLE CIRCUIT COIL PIPING CONFIGURATION

FOR SINGLE COMPRESSOR CONDENSING UNITS

DUAL CIRCUIT COIL PIPING CONFIGURATION

FOR SINGLE COMPRESSOR CONDENSING UNITS

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

INDOOR

COIL CKT

AIRFLOW

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

TXV

FILTER DRIER

A LOCATION

LIQUID LINE

SOLENOID

VALVE

FLOW

LIQUID LINE

SOLENOID

VALVE

MODEL

QTY

LSV

RELAY SVR

QTY - PART NUMBER

TRAN3 PRIMARY V:

PART NUMBER

569J***

A/B/G/H

11 — HN61PC005 N/R

2 2 — HN61PC005 208/230V: HT01BD202

569J***D/E/F 22 — HN61PC005

460V: HT01BD702

575V: HT01BD902

569J*12F 2 1 — HN61PC005* N/R #

LSV — Liquid Solenoid Valve

SVR — Solenoid Valve Relay

N/R — Not Required

N/R # — Not Required / Factory Installed

AIRFLOW

SUCTION

CIRCUIT 2

SUCTION

CIRCUIT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT

GLASSES

TXV

CKT 2

FILTER

DRIERS

LIQUID LINE

SOLENOID VALVE

CIRCUIT 2

FLOW

LIQUID LINE

SOLENOID VALVE

CIRCUIT 1

FLOW

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

DUAL CIRCUIT COIL PIPING CONFIGURATION

FOR TWO CIRCUIT CONDENSING UNITS

Loading...

Loading...