10

MA671635_13.1 [Original Instructions] 1/23/2012

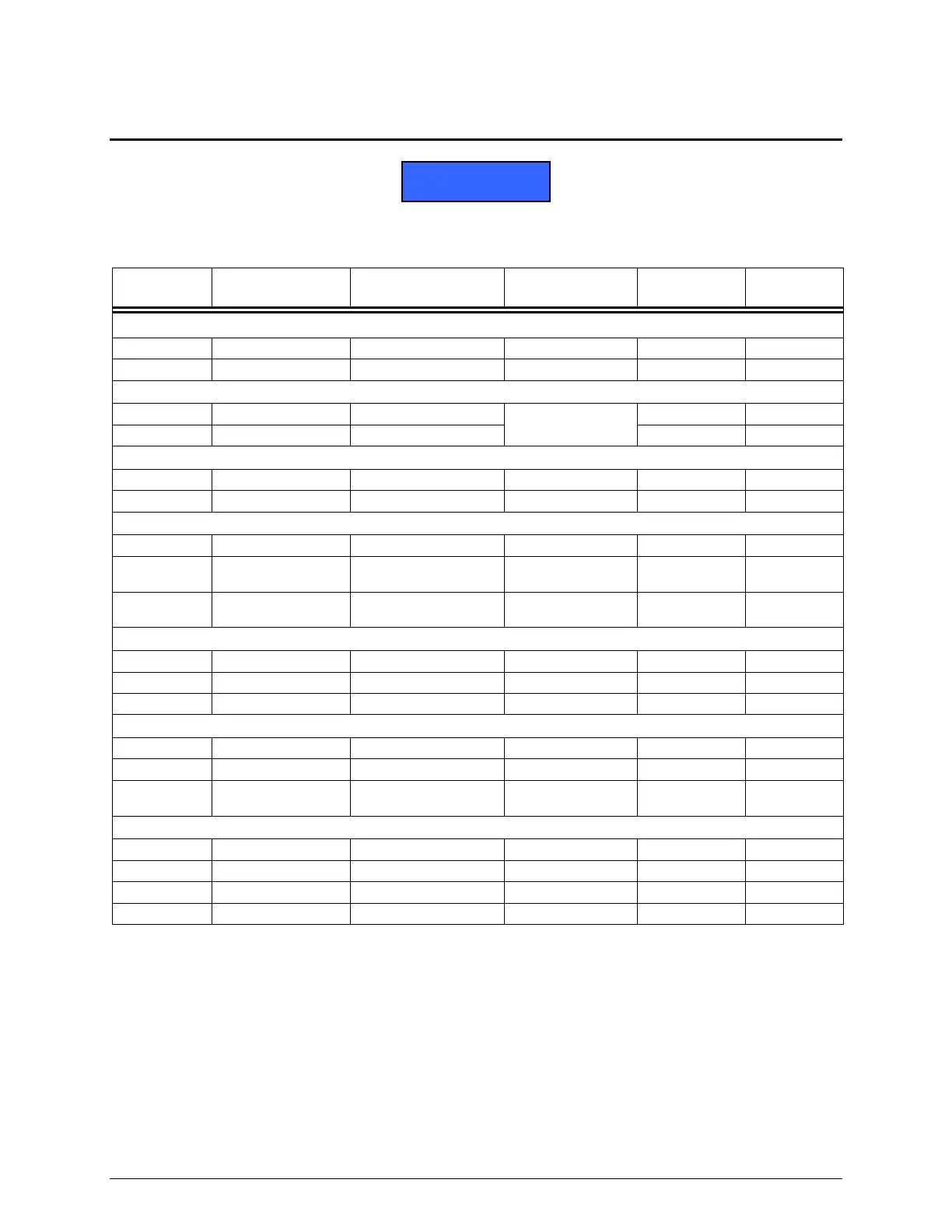

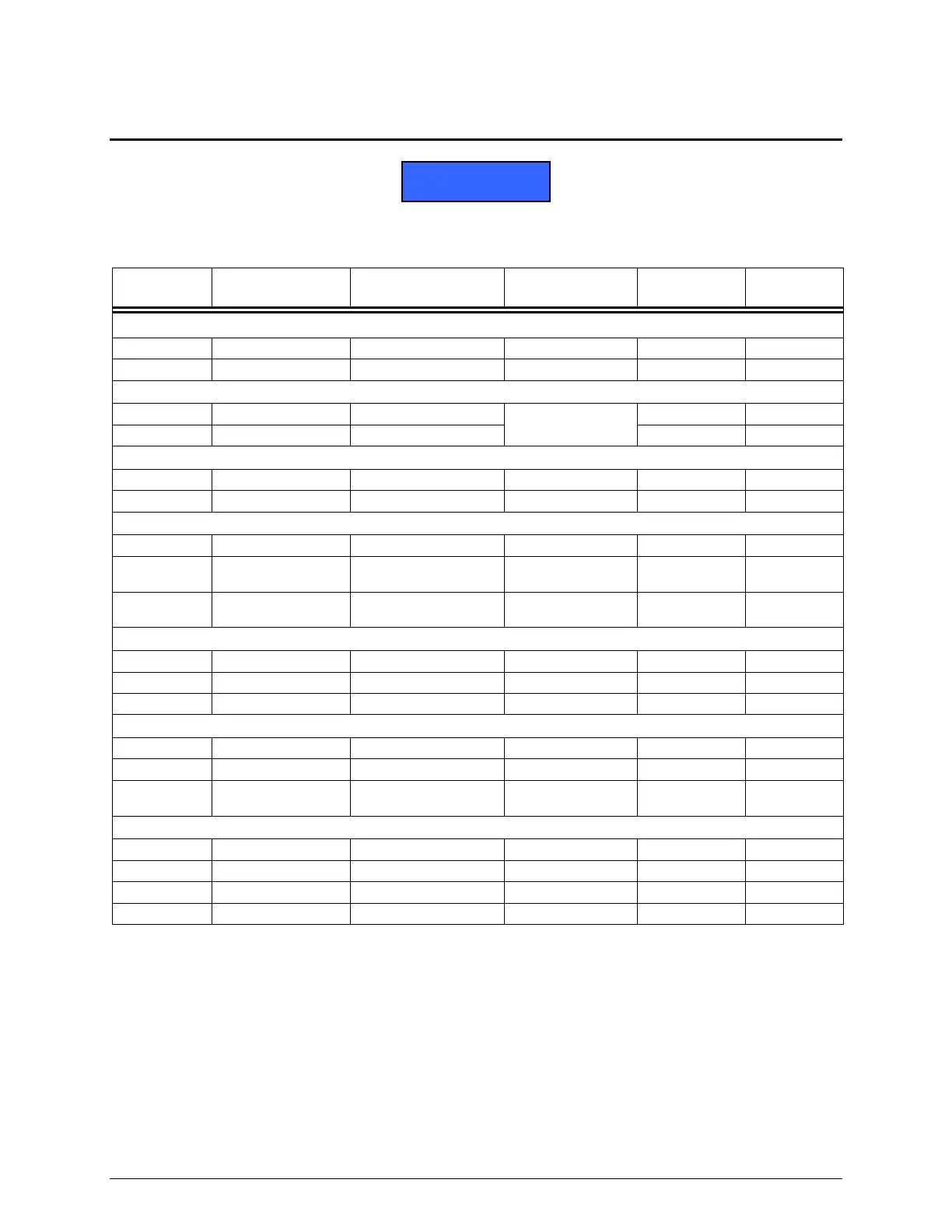

VibroMet 2 Recommended Polishing Procedures

These recommendations are guidelines to assist in determining the best procedure for a specific

specimen material.

Starting

Condition

Surface or

Covering

Abrasive Type/Style

Lubricant

Approximate

Load

Vibratory

Times

Low to Medium Carbon Steel and General Purpose Procedure

600 grit TexMet

®

/ Nylon 6 micron Metadi

®

Metadi

®

Fluid 1 weight 60-240 min

6 micron MicroCloth

®

1 micron Metadi

®

Metadi

®

Fluid 1 weight 60-180 min

Graphite Irons for the retention of graphite

600 grit (dry) CarbiMet

®

3 micron

AutoMet

®

Lapping

Oil

1 weight 30-45 min

3 micron MicroCloth

®

1 micron Metadi

®

1 weight 30-45 min

Hard Ferrous Alloys

6 micron TexMet

®

3 micron Metadi

®

Fluid 2 weights 80-240 min

3 micron MicroCloth

®

1 micron Metadi

®

Fluid 2 weights 60-120 min

Stainless Steels, Nickel, Zirconium, and Hafnuim Alloys

600 grit TexMet

®

6 micron Metadi

®

Metadi

®

Fluid 1 weight 120-240 min

6 micron TexMet

®

/ Nylon

1 micron

.05 micron

Metadi

®

Fluid 2 weights 120-240 min

1 micron MicroCloth

®

Alumina /

MasterMet

®

Metadi

®

Fluid 2 weights 60-240 min

Aluminum, Brass, and other Non-ferrous Alloys

1200 grit TexMet

®

/ Nylon 3 micron Metadi

®

Fluid 1 weight 60-240 min

3 micron TexMet

®

/ Nylon 1 micron Metadi

®

Fluid 1 weight 120-240 min

1 micron MicroCloth

®

.06 micron MasterMet

®

None 120-240 min

PC Boards

1200 grit TexMet

®

/ Nylon 3 micron Metadi

®

Fluid 1 weight 60-180 min

3 micron TexMet

®

/ Nylon 1 micron Metadi

®

Fluid 2 weights 60-180 min

1 micron MicroCloth

®

.06 micron

MasterPolish

®

MasterMet

®

1 weight 30 min

Ceramics

15 micron TexMet

®

9 micron Suspensions 2-3 weights 120-360 min

9 micron TexMet

®

6 micron Suspensions 2-3 weights 120-360 min

3 micron TexMet

®

1 micron Suspensions 2-3 weights 120-360 min

1 micron TexMet

®

MasterMet

®

Suspensions 2-3 weights 120-360 min

Table 2 VibroMet 2 Recommended Polishing Procedures

Loading...

Loading...