21

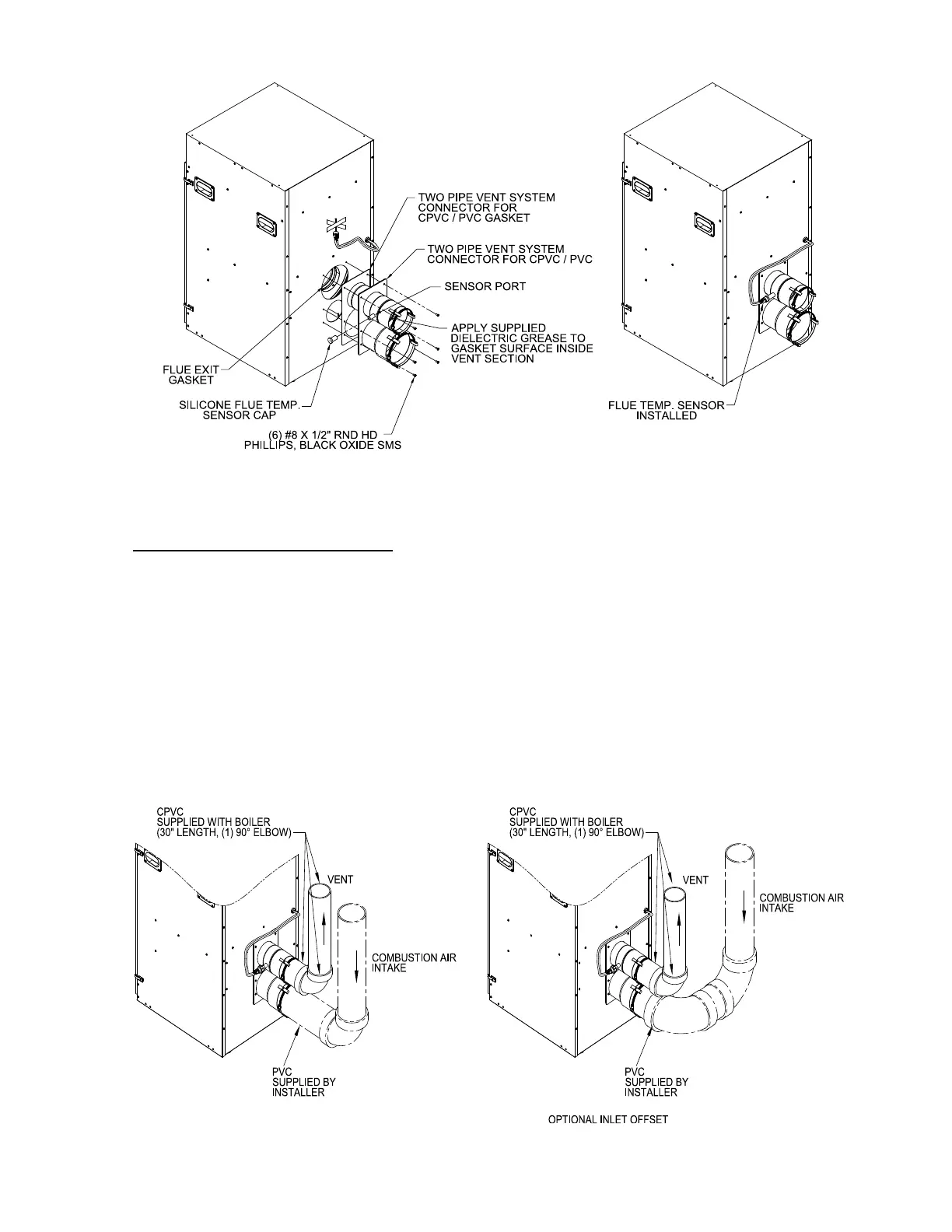

Figure 6: Field Installation of CPVC/PVC Two-Pipe Vent System Connector

IV. Venting B. CPVC/PVC Venting (continued)

4. Near-Boiler Vent/Combustion Air Piping

Refer to Figure 7 and the following Steps:

APX399 and APX500 Boiler Models:

a. 4” x 4” Two-Pipe CPVC/PVC Vent System

Connector (P/N 102183-03), used on APX399

and APX500 boiler models, has factory installed

internal sealing gaskets at both vent and air

intake sections.

b. Install provided 4” Schedule 40 x 30” long

CPVC pipe into the connector vent section with

a slight twisting motion and secure by tightening

the metal strap.

c. All CPVC vent components supplied with

boiler inside vent carton (4” Schedule 40 x 30”

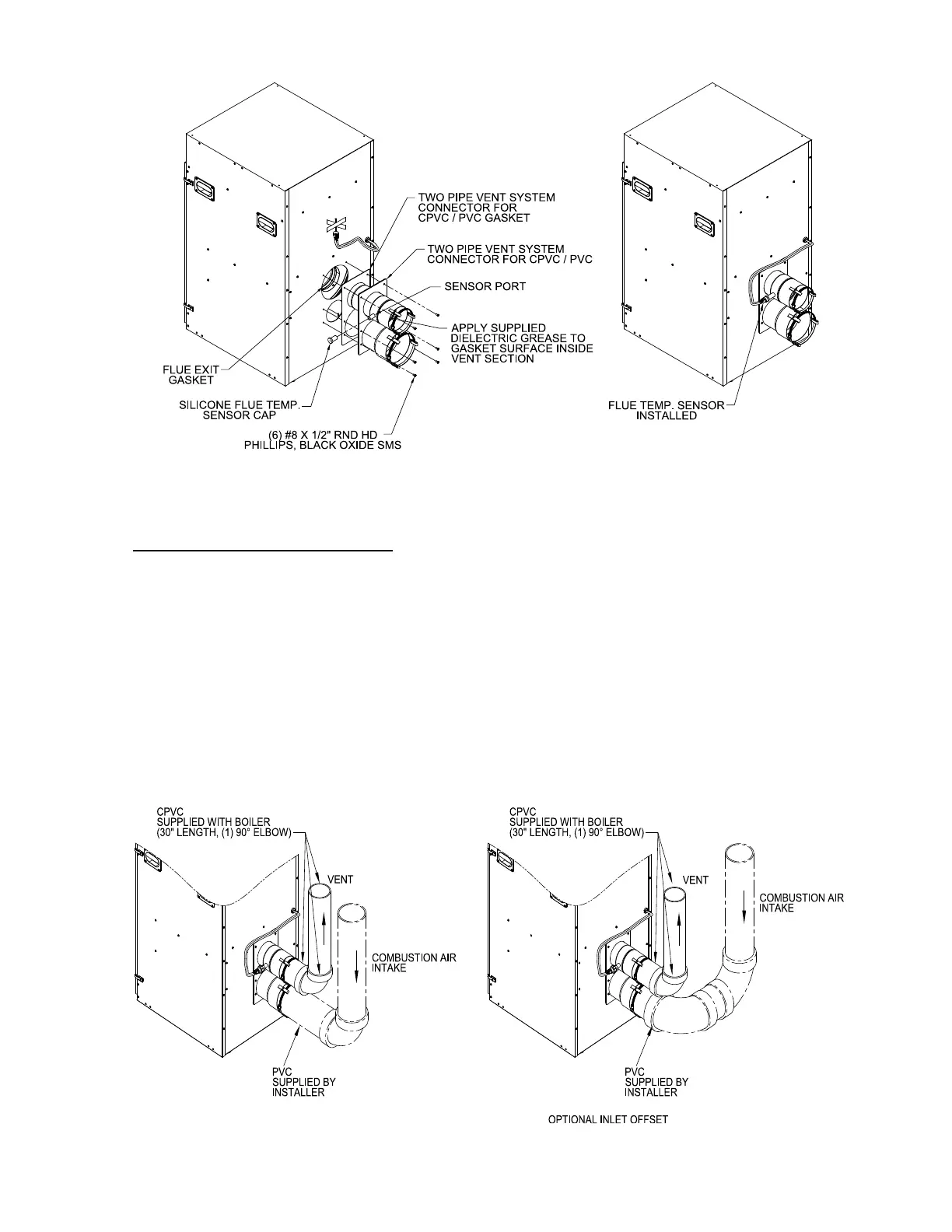

Figure 7: Near-Boiler Vent/Combustion Air Piping

long CPVC pipe and 4” Schedule 80 CPVC

90° Elbow) must be used for near-boiler piping

before transitioning to Schedule 40 PVC (ASTM

2665) pipe components for reminder of vent

system. The CPVC 30” long straight pipe may be

cut to accommodate desired vent conguration

provided both pieces are used in conjunction

with CPVC 90° Elbow before any PVC

components are used. Ensure that the CPVC 90°

Elbow is the rst elbow used in the vent system

as it exits the boiler.

d. Insert 4” Schedule 40 PVC combustion air pipe

(installer provided) into the connector air intake

section with a slight twisting motion and secure

by tightening the metal strap.

Loading...

Loading...