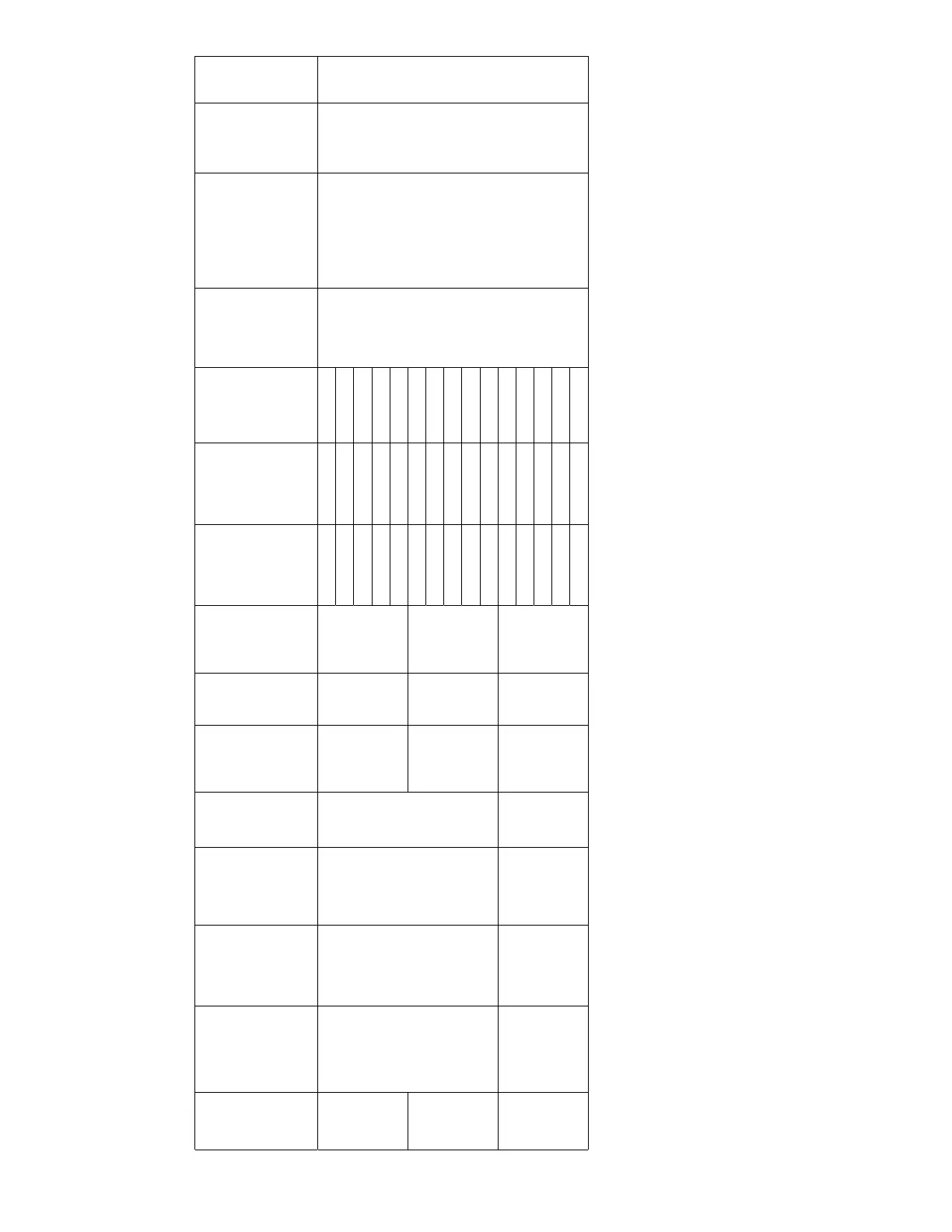

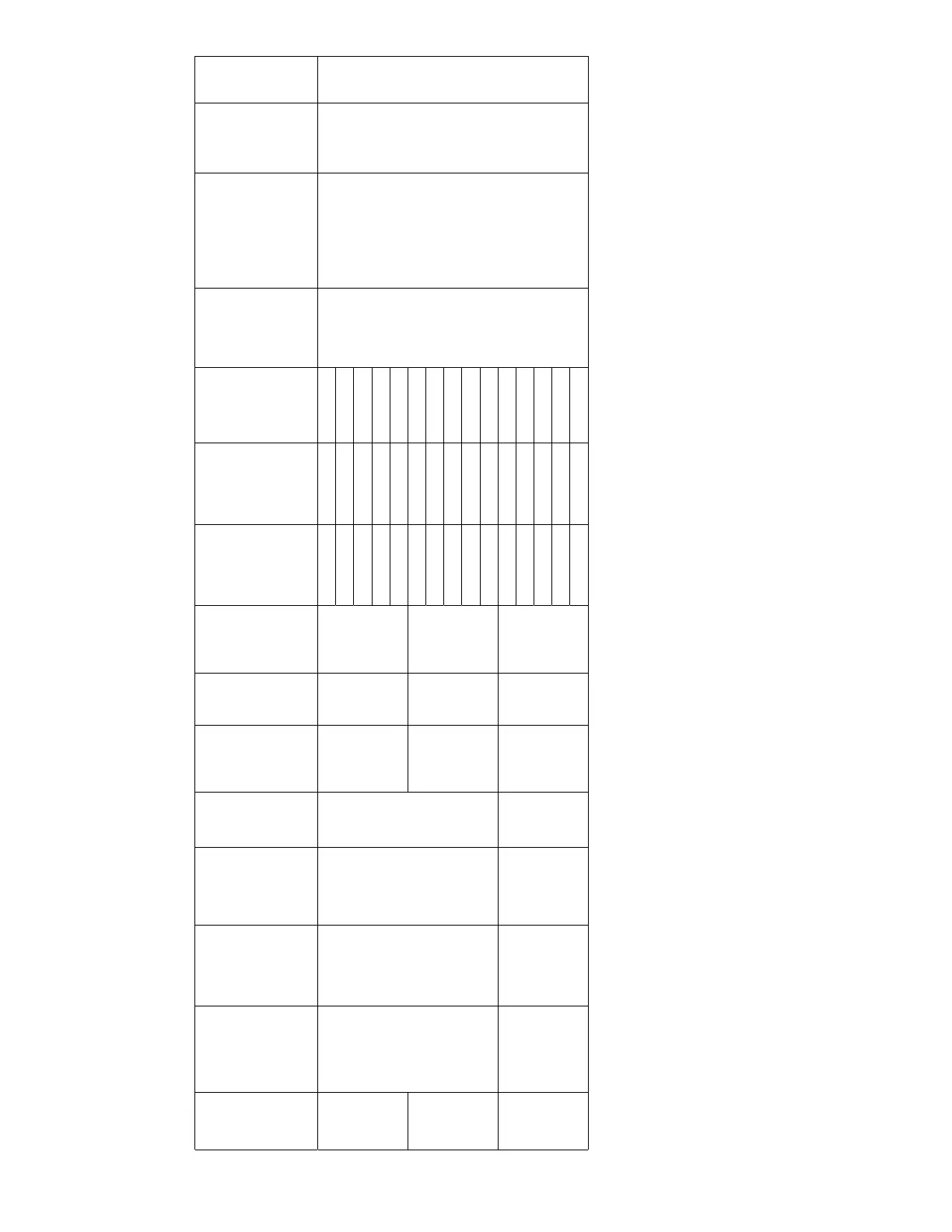

58

Boiler

Model

Boiler

Supply

Connection,

Inch, FPT

Boiler

Return

Connection,

Inch, FPT

Near-Boiler

Piping

Supply

Pipe Size,

Inch

(Note 2)

Near-

Boiler

Piping

Return

Pipe

Size,

Inch

(Note 2)

Max

Allowable

Flow thru

Boiler,

GPM @

20°F

DT

Flow,

GPM

@ 25°F

DT

Min Req’d

Flow thru

Boiler,

GPM

@ 35°F

DT

Alliance SL

Models to

be installed

As Part of

Near-Boiler

Piping

Alliance SL

Coil

Required

Flow Rate,

GPM

Alliance SL

Coil Head

Loss, Ft @

Required

Flow Rate

Combined

Boiler,

Alliance SL

& Piping

Loop Head

Loss, Ft

*Recommended

Circulator Make &

Model for

Alliance SL

installed as Part

of Near-Boiler

Piping

Reference

Figure

Notes

APX399

1-1/2 1-1/2 2 2

37.7 30.2 21.5

SL27 6 9

NA

*Not

Recommended

(see Notes 1

and 2)

40A & 40B

40A & 40B

Note 1

Note 2

SL35 6 9

SL50 6 9.5

SL70 6 10

SL119 14 17.0

APX500 47.2 37.8 27.0

SL27 6 9

SL35 6 9

SL50 6 9.5

SL70 6 10

SL119 14 17.0

APX800 2 2 2½ 2½ 76.0 60.8 43.4

SL27 6 9

SL35 6 9

SL50 6 9.5

SL70 6 10

SL119 14 17.0

Table 18: Recommended Circulator Models for Apex (APX) Boilers and Alliance SL Indirect Water Heaters

Installed as Part of Near-Boiler Piping Up to 75 Ft. Equivalent Length - Domestic Hot Water Circulator

NOTES:

Note 1: All Alliance SL Coil Flow Rates are below Min Required Flow Rate thru Boiler corresponding to boiler maximum ring rate. These Alliance models can only be installed as separate heating zone off system header - see

Figure 39A and 39B for IWH piping.

Indirect Water Heater Circulator must be selected by an installer based on Alliance SL required coil ow and corresponding coil head loss shown as well as total equivalent length of such separate zone.

Note 2:

* The IWH may be installed as part of Boiler piping when boiler DHW modulation rate (input) is adjusted to closely match the IWH rated heating capacity required to satisfy DHW demand (see Figures 40A and 40B).

IMPORTANT – Shared or Isolated DHW Demand

When the IWH parameter is set to “Primary Piped”, the Sequence Master will be sequencing all required boilers to satisfy the DHW setpoint (default 180°F). Do not use the “Boiler Piped” parameter for 500 and 800 models,

unless IWH is piped off an individual boiler having DHW modulation rate (input) adjusted to closely match the IWH rated heating capacity required to satisfy DHW demand. Otherwise, piping an IWH of an individual boiler could

cause higher than normal velocities or DT’s thru that boiler because of required IWH ow. For commercial applications, it is recommended to pipe IWH’s off the common header piping. A header sensor must be installed to

prevent rapid header temperature rise when the Sequence Master is sequencing all required boilers to satisfy the DHW setpoint (default 180°F).

Note 3: Near-Boiler Piping Size shown is based on 2 to 5.5 Ft/sec velocity range to avoid potential noise and pipe erosion.

VI. Water Piping and Trim E. Multiple Boiler Installation (continued)

Loading...

Loading...