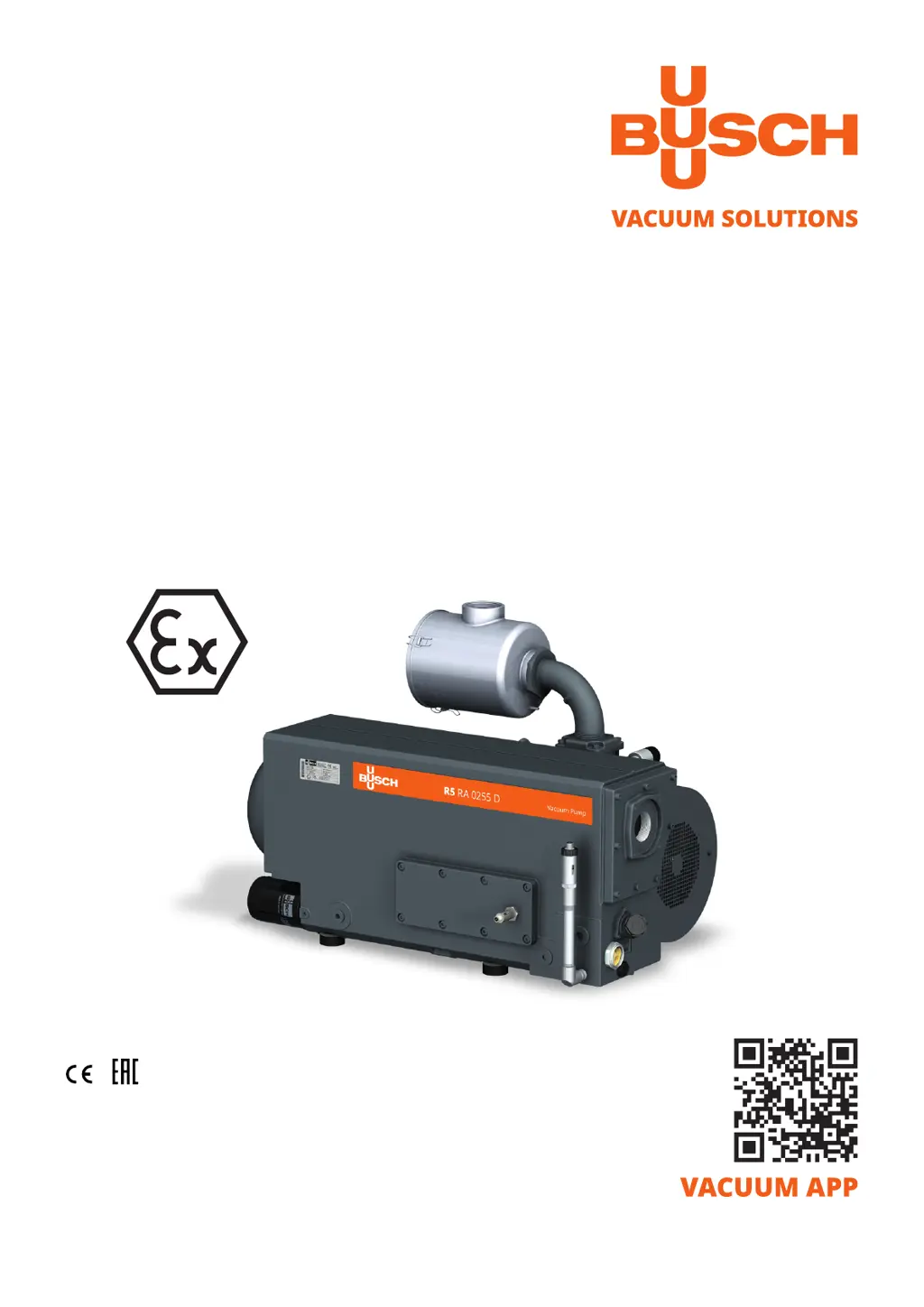

What causes a BUSCH Water Pump to fume or expel oil?

- MmurphyericaSep 23, 2025

If your BUSCH Water Pump is fuming or expelling oil droplets through the gas discharge, the exhaust filters (EF) might be partially clogged and need replacement. Ensure that the exhaust filter (EF) with o-ring is fitted correctly. Another possible cause is a malfunctioning float valve (FV); inspect it and the oil pipe for any blockages, and clear them if necessary.