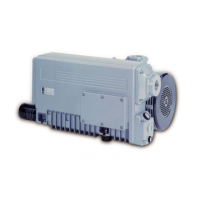

The Busch R 5 RA 0063 F and RA 0100 F are rotary vane vacuum pumps designed for industrial use. These machines operate on the rotary vane principle, where oil plays a crucial role in sealing gaps, lubricating vanes, and dissipating compression heat. The circulating oil is continuously cleaned by an integrated oil filter, and exhaust filters separate oil from the discharged gas, ensuring clean operation.

Function Description:

The R 5 series vacuum pumps are primarily intended for the suction of air and other dry, non-aggressive, non-toxic, and non-explosive gases. Conveying other media is permissible only after consultation with Busch, as it can lead to increased thermal and/or mechanical load on the machine. These pumps are designed for placement in non-potentially explosive environments and are capable of maintaining ultimate pressure.

There are two main versions:

- Version with float valve (standard): This version is suitable for continuous operation.

- Version with oil return valve: In this configuration, oil accumulates in the upper chamber of the oil separator during operation and cannot flow down into the bottom chamber while the machine is running. To ensure proper oil return, the machine must be shut down for at least 15 minutes after 10 hours of continuous operation, or sooner if there's a high-pressure difference between the suction and pressure sides. This allows the oil to drain from the upper to the bottom chamber of the oil separator.

Optional Accessories:

- Gas Ballast Valve (GB): This valve mixes the process gas with a limited quantity of ambient air to prevent condensation of vapor inside the machine, particularly useful when conveying condensable vapors.

- Inlet Filter: Protects the machine from dust and other solid particles in the process gas. It is available with either a paper or polyester cartridge.

Important Technical Specifications:

The R 5 RA 0063 F and RA 0100 F models offer varying performance characteristics:

| Specification |

RA 0063 F |

RA 0100 F |

| Nominal pumping speed (50Hz / 60Hz) |

63 / 76 m³/h |

100 / 120 m³/h |

| Ultimate pressure |

See nameplate |

See nameplate |

| Nominal motor rating (50Hz / 60Hz) |

2.0 / 2.4 kW |

2.7 / 3.4 kW |

| Nominal motor speed (50Hz / 60Hz) |

1500 / 1800 min⁻¹ |

1500 / 1800 min⁻¹ |

| Noise level (EN ISO 2151) (50Hz / 60Hz) |

64 / 67 dB(A) |

65 / 68 dB(A) |

| Water vapor tolerance max. (with gas ballast valve) |

40 hPa (mbar) |

40 hPa (mbar) |

| Water vapor capacity (with gas ballast valve) |

1.8 l/h |

2.8 l/h |

| Operating temperature (50Hz / 60Hz) |

84 / 92 °C |

84 / 93 °C |

| Ambient temperature range |

See Oil section |

See Oil section |

| Ambient pressure |

Atmospheric pressure |

Atmospheric pressure |

| Oil capacity |

2.0 l |

2.0 l |

| Weight approx. |

55 kg |

73 kg |

Oil Types:

Busch offers various oil types suitable for different ambient temperatures and applications:

- VM 032 (ISO-VG 32): For ambient temperatures 0...10 °C.

- VM 068 (ISO-VG 68): For ambient temperatures 5...20 °C.

- VM 100 (ISO-VG 100): For ambient temperatures 12...30 °C.

- Remark for VM series: Standard oil for non-demanding applications.

- VE 101 (ISO-VG 100): For ambient temperatures 12...40 °C.

- Remark: For thermally and chemically demanding applications.

- VMH 100 (ISO-VG 32): For ambient temperatures 12...30 °C.

- Remark: For ultimate pressure critical applications.

- VSL 032 (ISO-VG 68): For ambient temperatures -5...10 °C.

- VSL 068 (ISO-VG 100): For ambient temperatures 5...20 °C.

- VSL 100 (ISO-VG 100): For ambient temperatures 10...40 °C.

- Remark for VSL series: Food applications (NSF H1).

The specific oil filled in the machine can be identified on the nameplate (NP).

Usage Features:

- Installation: The machine must be installed horizontally (max. 1° deviation) in a well-ventilated area, ensuring sufficient cooling air flow and unobstructed inlets/outlets. A minimum clearance of approximately 20 cm around the machine is recommended for proper ventilation and maintenance access. The oil sight glass (OSG) must remain easily visible.

- Electrical Connection: Electrical installation must be performed by qualified personnel, ensuring compatibility with motor nameplate data, proper overload protection (EN 60204-1), and connection of the protective earth conductor. Incorrect wiring can damage the motor, so internal terminal box diagrams should be checked. The direction of rotation must be verified (using the arrow on the machine or by "bumping" the motor) and corrected if necessary by switching any two motor phase wires.

- Commissioning: Before commissioning, the machine must be filled with the correct oil type and quantity. Operation without oil will quickly ruin the machine. During operation, the machine's surface can reach temperatures over 70°C, posing a burn risk. Ear protection is recommended if persons are present near a non-noise insulated machine for extended periods. The oil level should be checked and topped up after a few minutes of operation. For versions with an oil return valve, periodic shutdowns are necessary to allow oil to drain.

- Conveying Condensable Vapors: If condensable vapors are to be conveyed, the gas ballast valve (if installed) should be open. The machine should be warmed up for approximately half an hour before the process and operated for another half an hour after the process to ensure proper function and prevent condensation.

Maintenance Features:

Regular maintenance is crucial for the machine's longevity and efficiency. Maintenance intervals are dependent on operating conditions and may need adjustment for heavy-duty use or contaminated process gases.

- Weekly: Check oil level and inspect for oil leaks.

- Monthly: If an inlet filter is installed, check and replace the cartridge if necessary.

- Every 2000 hours (or at least every 6 months): Change the oil, oil filter (OF), and exhaust filters (EF).

- Every 6 months: Clean the machine from dust and dirt. If a gas ballast valve (GB) is installed, clean its filter.

- Every 5 years: A major overhaul is recommended (contact Busch).

Maintenance Procedures:

- Oil and Oil Filter Change: This involves draining the old oil from the oil drain plug (ODP), replacing the oil filter (OF), and refilling with new oil through the oil fill plug (OFP) to the MAX level indicated on the oil sight glass (OSG). An o-ring (part no. 0486 000 505) is required for the oil drain plug. The oil filter (part no. 0531 000 002) is a genuine Busch spare part.

- Exhaust Filter Change: This involves removing the exhaust filter housing (typically secured by 8 screws), replacing the two exhaust filters (EF, part no. 0532 140 157) and the two flat gaskets (part no. 0480 000 112), and reassembling.

- Troubleshooting: A comprehensive troubleshooting guide is provided to address common issues such as the machine not starting, not reaching usual pressure, running noisily, running too hot, fuming, or having black or emulsified oil. Solutions range from checking power supply and oil levels to replacing components like the motor, coupling, filters, or contacting Busch for repairs.

Safety:

Prior to any handling or maintenance, the instruction manual must be read and understood. Safety notes and warnings are categorized as DANGER, WARNING, CAUTION, NOTICE, and NOTE, indicating the severity of potential hazards. Personal protective equipment must be worn when handling machines contaminated with hazardous materials. Before touching the machine for maintenance, it must be shut down, locked against inadvertent start-up, vented to atmospheric pressure, and all connections disconnected to prevent burns from hot surfaces.

Spare Parts:

Only genuine Busch spare parts and consumables are recommended to ensure proper machine function and warranty validity. A service kit (part no. 0992 106 214) is available, including all necessary parts for maintenance. For other parts, contact a Busch representative.

Decommissioning and Disposal:

For decommissioning, the machine must be shut down, locked, vented, and disconnected. For storage, refer to the storage instructions. For disposal, drain the oil, remove exhaust and oil filters, separate special waste, and dispose of all components according to applicable regulations, with the machine itself disposed of as scrap metal.