HELiOS Portables Technical Service Manual • PN 20562190 Rev E

41

HELiOS Portables

Troubleshooting & Repair Procedures

XI

RP12 – Pressure Hold Test

1. Attach a test pressure gauge (B-701732-00) to the top can-

nula barb on the front cover of the H300 or H850.

2. Set the flow control knob to a continuous flow setting (0.75

on the H300, C6 on the H850).

3. Attach the DISS nut and tailpiece of a HELiOS oxygen sup-

ply line (B-701656-SV) to a 0-6.90 bar (0-100 psi) source of

gaseous oxygen.

4. Insert the opposite end of the HELiOS oxygen supply line in

the quick connect.

5. Increase the gaseous oxygen source pressure until the test

pressure gauge reads 1.52 bar (22 psi) for the H300, or 1.65

bar (24 psi) for the H850.

6. Disconnect the HELiOS oxygen supply line from the quick

connect.

7. Allow the unit to sit undisturbed for 10 minutes.

8. Verify that the portable maintains a minimum pressure of

1.03 bar (15 psi) for the H300, or 1.24 bar (18 psi) for the

H850 at the end of the evaluation period.

9. If the pressure drops below this level, locate the leak by per-

forming the liquid leak detector test (RP2).

10. Disconnect the test pressure gauge.

NOTE: If you do not get a reading on the pressure gauge, reset

the demand valve as follows. Connect one tube of a dual-lumen

cannula to the bottom cannula barb and breathe in once or

twice.

NOTE: If unit was equipped without CPC fitting, remove kit

and reinstall tube in reverse order of RP27, then reinstall front

case.

NOTE: For newer units manufactured without the CPC

Connector, the CPC Connector Kit will need to be installed

first, refer to RP27, then reinstall the front case.

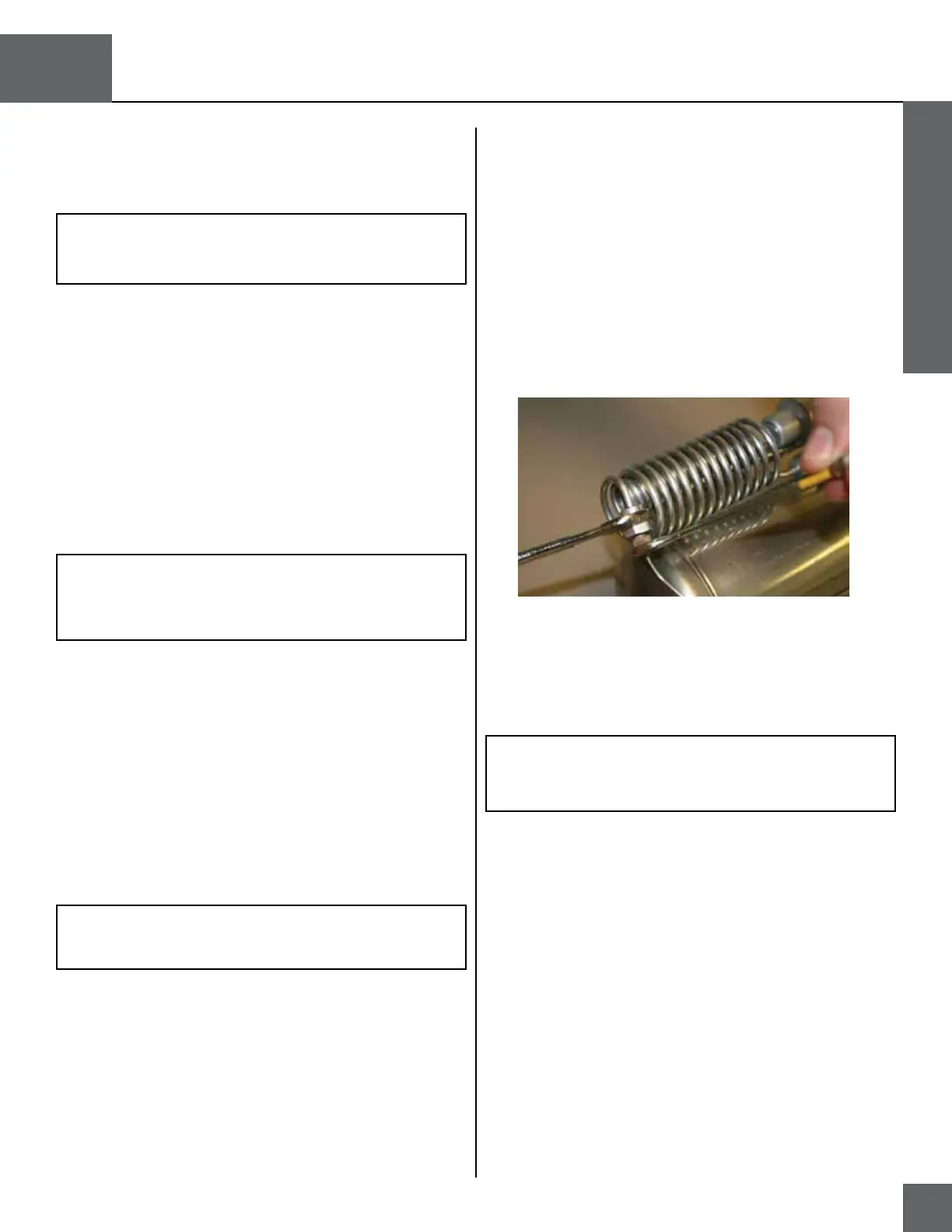

RP13A – Liquid Withdrawal Warming Coil R/R (H300)

1. Remove the covers (RP4).

2. Use an adjustable wrench to hold the R/E valve outlet arm

(with barbed fitting) stationary. Use a 7/16 inch open-end

wrench to remove the liquid withdrawal warming coil com-

pression nut from the R/E valve fitting.

3. Use a 5/16 inch open-end wrench to hold the fitting on the

stainless steel container tube stationary. Use a 7/16 inch

open-end wrench to remove the remaining liquid withdrawal

coil compression nut from the fitting.

4. Pull the ends of the warming coil from their fittings and re-

move the coil.

5. To reinstall the warming coil, reverse steps 1-4.

Figure 33: Compression Nut Removal

NOTE: Make sure to route the flexible urethane vent tube

through the inside of the warming coil positioned directly

below the vent valve.

Loading...

Loading...