4

4-10. Adjusting Pulsation Dampener (See Figure 2-1)

1. Remove dust cover and insert 1/8 hex key into needle valve.

2. Turn valve clockwise to closed position, approx. 3 turns.

3. Back out valve 1/2 turn or as required to reduce pulsations/shock pres-

sures.

4-11. Troubleshooting

See Table 4-5 and refer to actuated instrument Manual for more information.

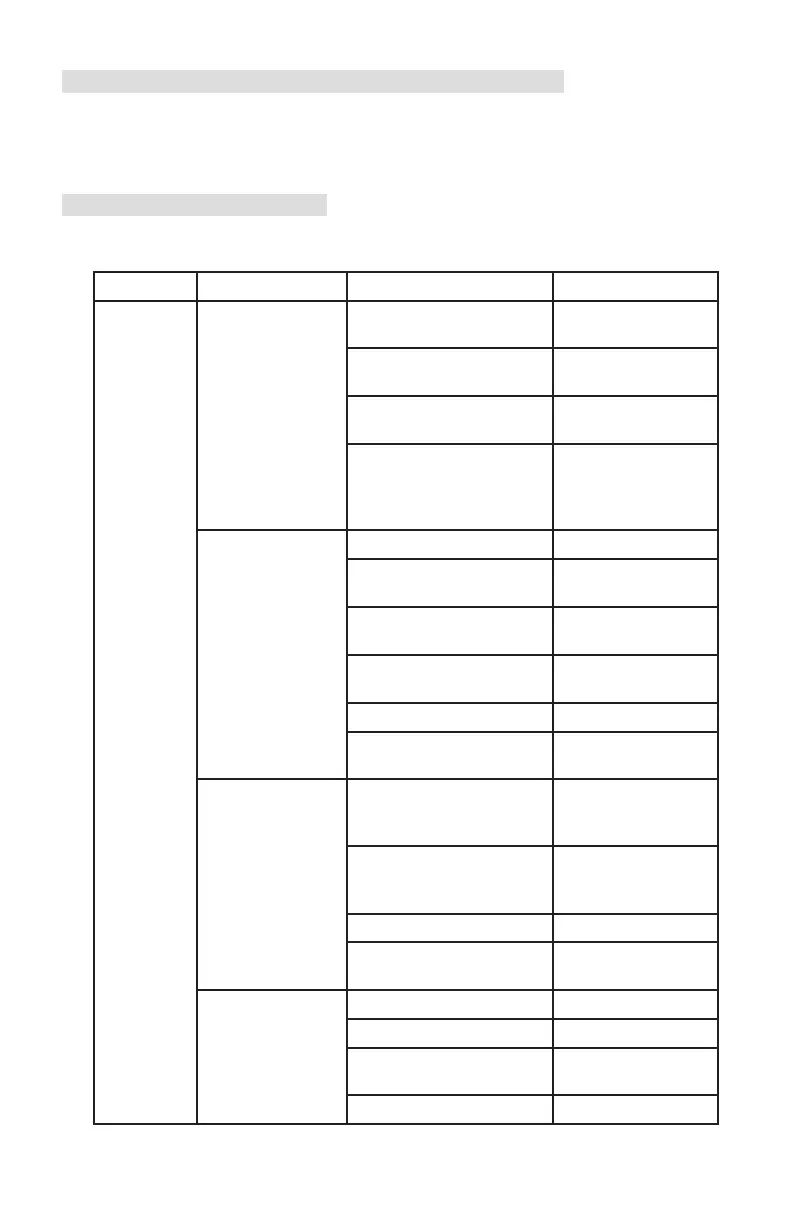

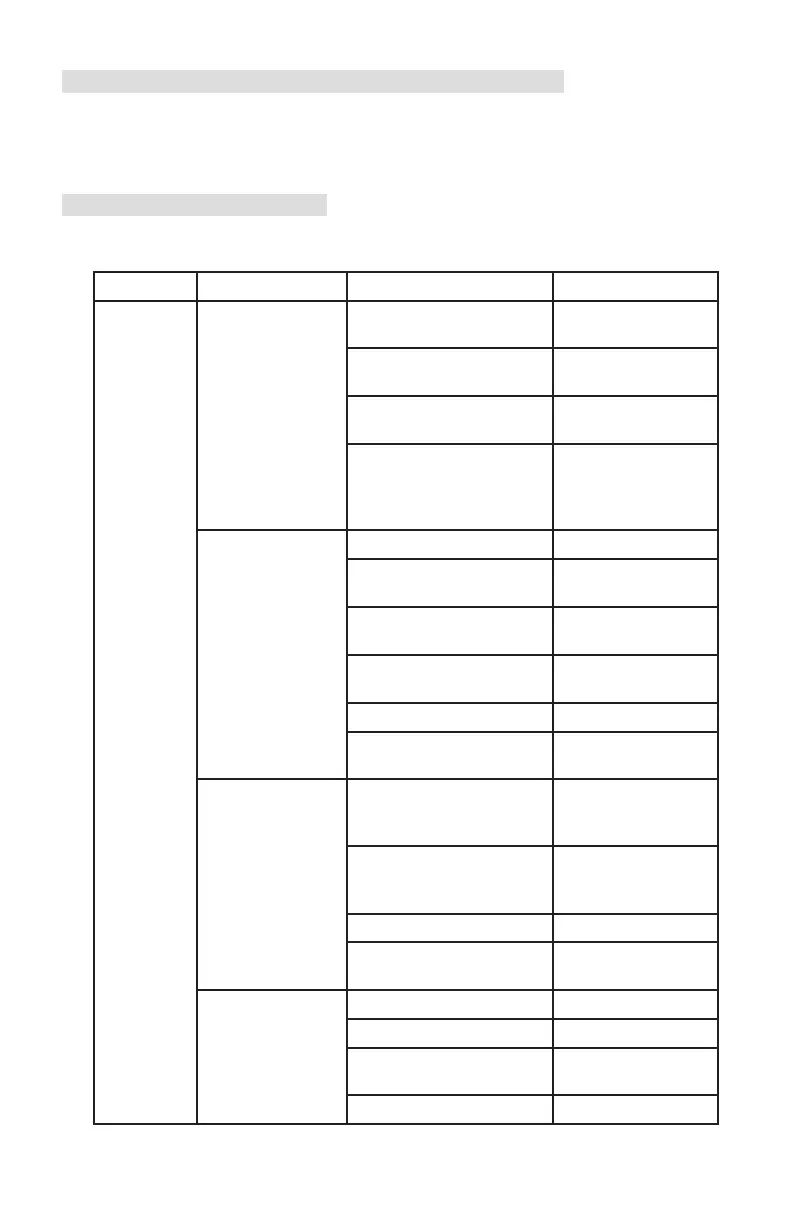

Table 4-5. Troubleshooting Chart

Trouble* Possible Source Probable Cause Corrective Action

Low or No Primary Element Orice installed backwards Replace orice

Indication or Differential or oversized

Pressure Source

Flow blocked upstream Clean out run or

from run open valve

Loss of liquid in reference Rell reference leg

leg (liquid level)

Density changes in process Rell reference leg

media or reference leg with same density

liquid as process

media

Piping from Pressure tap holes plugged Clean out piping

Primary Element

to DP

U

Bypass valve open or

leakin

g

Close bypass valve(s)

or repair leak

s

Liquids or gases trapped Vent piping

in piping

Block or shutoff valves Open block or shut-

closed off valves

Piping leaks, HP side Repair leaks

High apper setting Align drive arm

re-calibrate

Bellows Unit Housing(s) lled up with Clean out housing(s)

solids, restricting bellows

movement

Gas trapped (liquid service) Vent housing(s)

or liquid trapped (gas

service) in housing(s)

HP Housing gasket leaks Replace gasket

DPU tampered with Return BUA for

repair

Mechanism Loose links/movements Tighten or replace

Out of calibration Calibrate

Corrosion or dirt in mecha- Clean or replace

nism

Pointer loose Tighten pointer

25

Loading...

Loading...