ENGINEERED & PROCESS VALVES

4

07/2011 / IOM-GEN-TWIN-03

Installation, Operation and Maintenance Manual

INSTALLATION

Orientation

Twin Seal valves may be installed in any position.

Flow Direction

The Twin Seal design is symmetrical. Flow shut-off is

achieved equally on both sides of the plug independent

of flow direction.

Note: The use of a Differential Thermal Relief (DTR) as

described on page 29 does result in a preferred

flow direction.

Clearance for Repair

For easy repair, space should be allowed below the valve for

removal of the lower plate and withdrawal of the seating

slips. See Table 1 for dimensions. Sufficient clear space is

required above the Twin Seal valve, to allow free movement

of the position indicator flag and for removal of the opera-

tor mechanism.

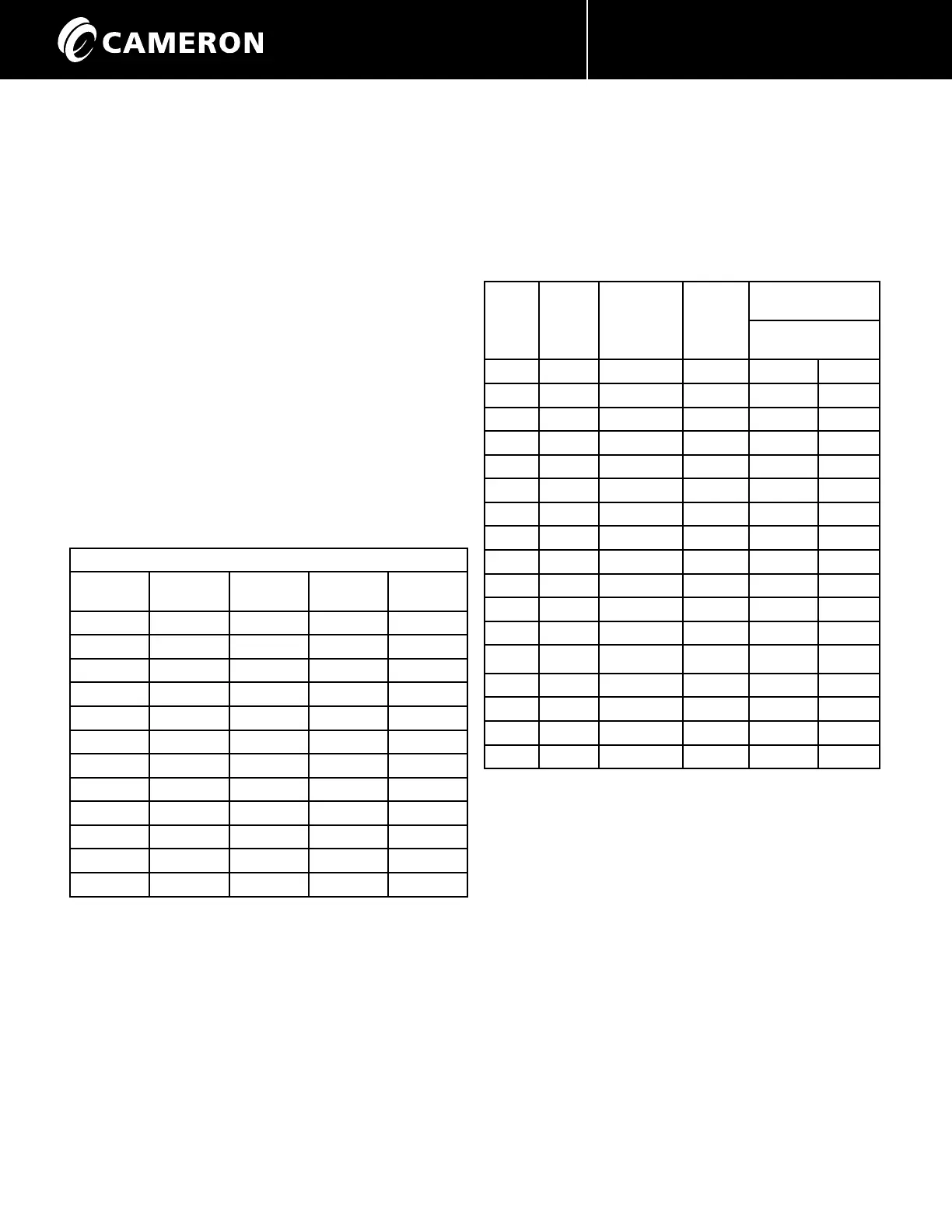

TABLE 1

Clearance required below standard ported valves for

slip removal.

Minimum Clearance

Valve Size

Inch

ASME Class

150

ASME Class

300

ASME Class

600

ASME Class

900

6” 9” 9” 10” 8”

8” 13” 11” 12” 10”

10” 15” 13” 8” 10”

12” 17” 16” 10” 10”

14” 19” 15” 10” xxxx

16” 22” 19” 14” xxxx

18” 23” 13” xxxx xxxx

20” 26” 14” 14” xxxx

24” 28” 17” 12” xxxx

28” 30” 12” xxxx xxxx

30” 30” 28” xxxx xxxx

36” 30” xxxx xxxx xxxx

Note: Allowing more than the specified minimum amount of

clearance will make servicing easier.

Flange Fasteners

Certain Twin Seal flange holes are drilled and tapped, when

there is no possibility of fitting a hexagonal nut behind the

flange. The quantity and size of these tapped holes is shown

in Table 2. Capscrews or stud bolts may be used in

these holes.

TABLE 2

Valve

Size

(inch)

ASME

Class

150

Number of

Tapped

Holes

per Flange

Thread

UNC

Length Required

(inch)

Cap Stud

Screws or Bolts

6 150 4 3/4”-10 2 1/4 3 1/4

8 150 4 3/4”-10 2 1/4 3 1/4

8300 4 7/8”-9 3 4 1/4

10 150 4 7/8”-9 2 1/4 3 1/4

10 300 4 1”-8 3 4 1/4

12 150 4 7/8”-9 2 1/4 3 1/2

12 300 4 1 1/8”-8 3 1/2 5

14 150 8 1”-8 2 1/2 4

14 600 4 1 3/8”-8 3 3/4 4 3/4

16 150 8 1”-8 2 1/2 3 3/4

18 150 8 1 1/8”-8 3 4 1/4

20 150 8 1 1/8”-8 3 4 1/2

24 150 8 1 1/4”-8 3 1/4 4 3/4

24 600 8 1 7/8”-8 5 1/4 6 3/4

28 150 6 1 1/4”-8 3 1/4 4 1/2

28 300 6 1 1/4”-8 3 1/4 4 1/2

30 150 6 1 1/4”-8 3 1/4 4 1/2

Gear Housing Orientation

On gear-operated models the gear housing and associated

hand wheel may be re-positioned as follows:

A) Place valve in fully open position.

B) Remove gear housing capscrews.

C) Turn hand wheel to further open the valve

which will turn the gear housing. Continue

until hand wheel comes to the desired position

and gear housing mounting holes are aligned.

D) Replace gear housing mounting capscrews.

NB: Short capscrew is inserted below the

worm shaft.

Loading...

Loading...