ENGINEERED & PROCESS VALVES

07/2011 / IOM-GEN-TWIN-03

5

Installation, Operation and Maintenance Manual

Valve figure No.

C411; C811; C911;

8811; C1611; C1500

C421; C821; C921;

8821; C1621; C1521

C441; C841; C941;

C1641; C1541

C851; C1651;

C1551

Comments

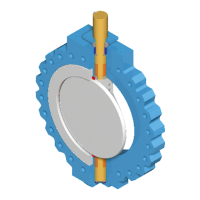

ASME Class 150 300 600 900

Shell Test Pressure

(Valve Open)

(pisg)

(kg/cm2)

500

35

1200

85

2250

158

3350

235

No leakage permitted

Seat Test Pressure (Valve Closed) (psig)

(kg/cm2)

300

21

800

56

1600

113

2400

168

Test upstream &

downstream seats. No

leakage permitted

Supplimentary (API 598) Air Seat Test

Pressure (Vavle Closed)

(psig)

(kg/cm2)

80

6

80

6

80

6

80

6

Test upstream &

downstream seats. No

leakage permitted

Pressure Test

Twin Seal valves can be hydrostatically pressure-tested after installation, to full API 6D limits per Table 3 below.

Table 3

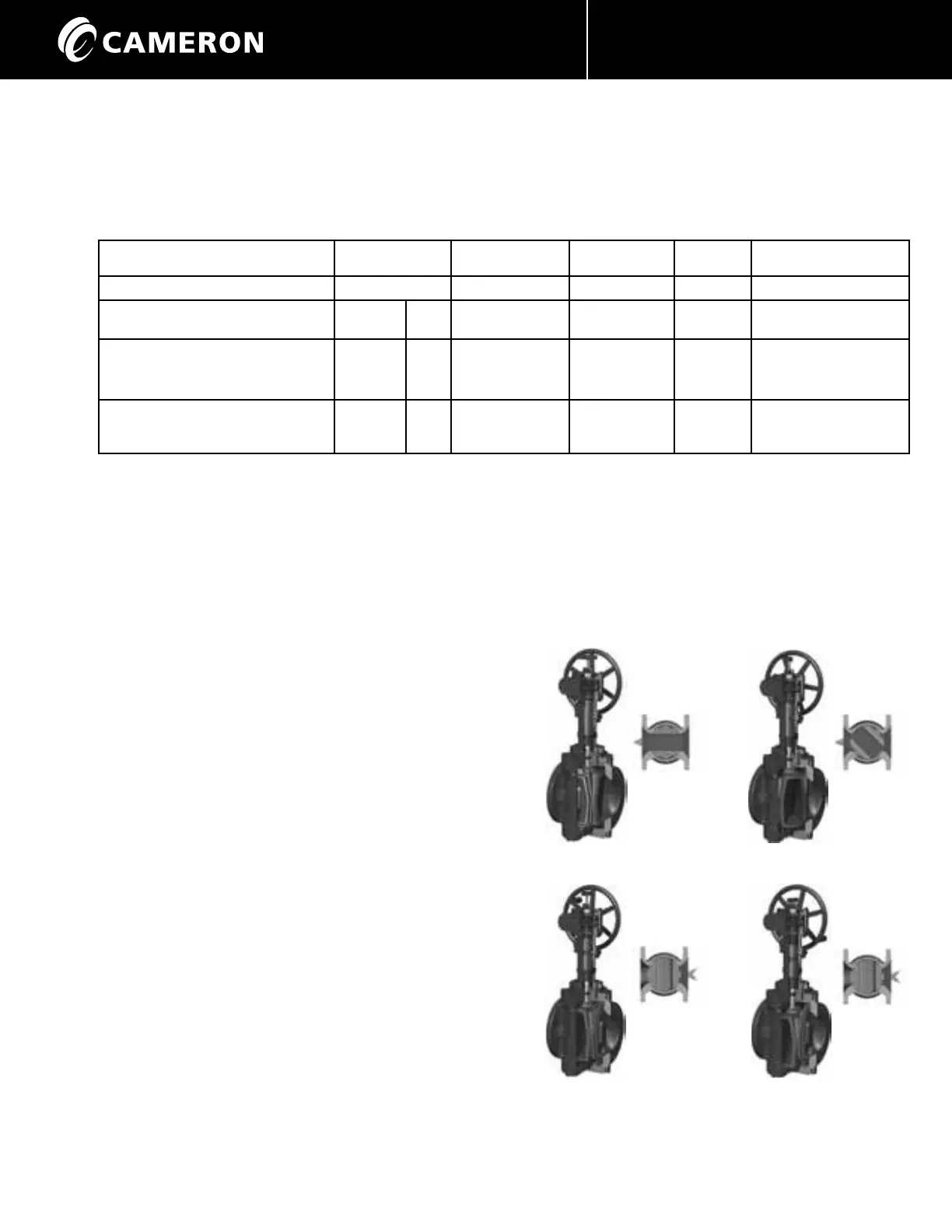

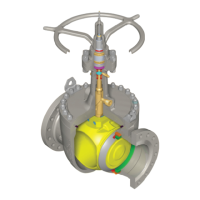

The Twin Seal valve is a non-lubricated, resilient seal, plug-

type valve which has a mechanical means of freeing the plug

before it is rotated from the closed to the open position.

In opening the valve, the plug is raised, thus retracting the

seating segments or slips through their tapered dovetail

connections. Only after the slips are fully retracted perpen-

dicularly from the body seat is the plug rotated to the open

position.

Conversely, in closing the valve, the plug and slips are

rotated freely, with no seal-to-body contact until the slips

are positioned over the ports. Then the plug is driven down

between the slips and the tapered surfaces wedge out the

slips for a positive upstream as well as downstream shut-off.

For maximum upstream sealing, do not back off the hand

wheel. Warning: Do not over torque by using cheater bars.

The small Twin Seal valves are handwheel operated, and

require up to 3 turns to open or close. Up to 2 3/4 turns

expand or retract the slips, while 1/4 turn rotates the plug.

Large valves operate in a similar manner, except that they

have enclosed weather-proof worm gearing.

At the top of the valve, a position indicator flag shows the

exact plug position. It appears in line with the flow when

the valve is open, and perpendicular to the flow when the

valve is closed.

OPERATION

Since Twin Seal valves hold bubble-tight, for ease of

opening in liquid service, it is important to prevent trapped

body pressure from exceeding the working pressure of the

valve. Therefore, a relief system is required to prevent pres-

sure buildup in the body cavity.

A

B

C

D

Loading...

Loading...