Maintenance

– 20 –

7. Maintenance

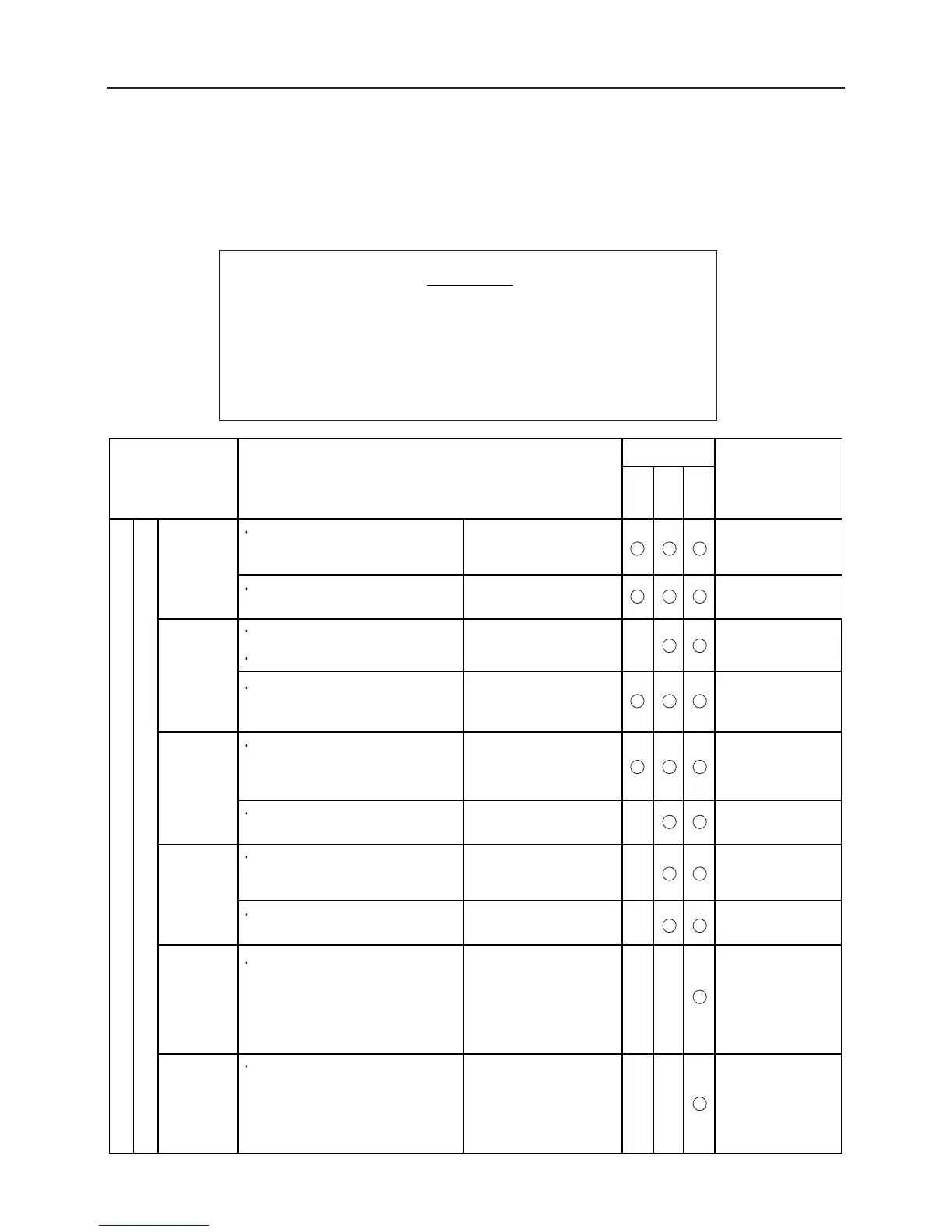

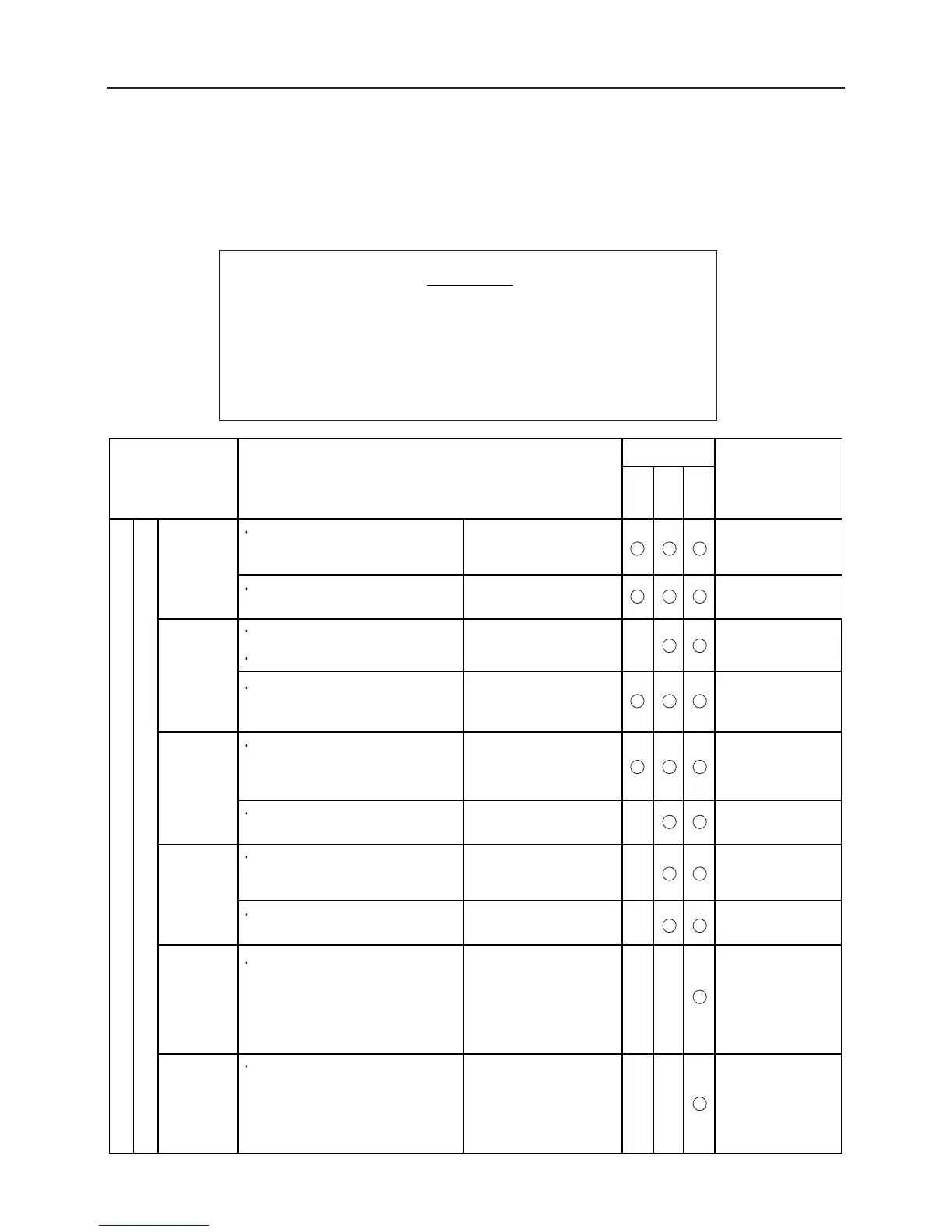

7.1 Periodic Inspection Table

Failure to carry out inspection and maintenance properly will cause machine failure.

Refer to the following table for inspection procedures and frequency.

Some inspection and maintenance procedures in the table

below require technical knowledge or specific tools and mea-

suring instruments. If you have difficulty performing these pro-

cedures, or do not have the correct tools or instruments,

contact your dealer or a Canycom service center.

Item Content of inspection Remarks

Investigate starting condition of

engine and check for abnormal

noise.

There must be no catching,

stalling of engine,

or knocking.

Exhaust gas color and

exhaust sound must be

normal.

There must be no cracks,

deformation of case,

looseness of cover or

connecting piping.

There must be no gas

leakage.

The valve clearance must be

normal.

There must be no noticeable

dirt or damage.

Must work properly.

Must be at specified speed.

Must rotate smoothly.

Check for catching of accelerator

lever when accelerating engine,

engine stall, or knocking.

Check speed at low idling and at

high idling.

Check that rotation is smooth.

Warm up engine thoroughly, then

check for abnormal exhaust gas

color or exhaust sound, low idling to

high idling.

Check if glow plug works prop-

ery.

Check for cracks, deformation of

case, looseness of cover or

connecting piping.

Check for looseness of nuts and

bolts at tightening portion of

cylinder head and manifold

*If no leakage of gas or water is

found from these portions, this

check can be omitted.

Check for dirty or damaged element.

Check for gas leakage from exhaust

pipe or muffler.

Check the valve clearance

* When noise due to abnormal valve

clearance is absent and the engine is

running smoothly, this inspection may

be omitted.

Ease of

starting

Condition

of rotation

Exhaust

gas

condition

Air cleaner

Tightening

Valve

clearance

Engine

Engine proper

Inspection

interval

Inspection

interval

Monthly

Annually

Checks

before

starting

Loading...

Loading...