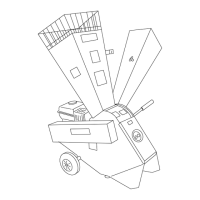

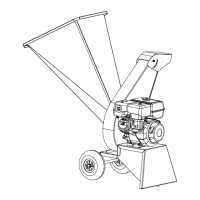

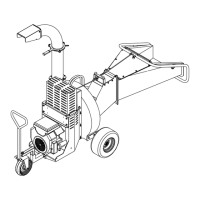

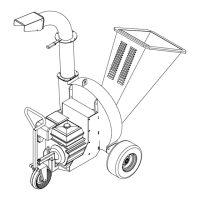

The Bio 80 is a professional-grade bio-chopper designed for processing organic materials such as vegetables, foliage, and natural wood. It is available in petrol engine, electric motor, and PTO (Power Take-Off) versions, catering to various operational needs. The machine is manufactured by Caravaggi, an industrial machinery company located in Pontoglio, Italy.

Function Description:

The primary function of the Bio 80 is to chop and shred organic waste, converting it into smaller, more manageable pieces. This process is beneficial for composting, mulching, or reducing the volume of garden and agricultural waste. The machine features two distinct hoppers: an upper hopper for smaller materials and a side hopper (chaff cutter) for larger branches.

Important Technical Specifications:

- Model: Bio 80 (available as Bio 80 B for petrol and Bio 80 MTC for MTC/PTO versions)

- Power (Petrol): 5÷9 HP / 8÷12 kW (Bio 80 B)

- Power (MTC/PTO): 6÷10 HP / 5.9÷8.9 kW (Bio 80 MTC)

- Production Capacity: 10 m³/h (data depending on material quality and feeding speed)

- Overall Dimensions:

- Breadth: 1100 mm

- Length: 500 mm

- High: 1200 mm

- Weight: 100 kg

- Noise Level (LWA MAX): 104 dB

- Material Processing Capacity:

- Upper hopper: materials up to 2.5 cm diameter

- Side hopper (chaff cutter): branches up to 7 cm diameter

- EC Directives Compliance: 98/37, 89/336, 73/23, 89/686, 91/368, 93/44, 93/68

Usage Features:

The Bio 80 is designed for professional use and requires the operator to have suitable experience and a thorough understanding of the instruction manual.

- Operation: The machine should be operated by a single person. Before starting, ensure no other persons or animals are within the working area.

- Material Compatibility: It is suitable for chopping vegetables, foliage, natural wood, peat, and similar materials. It is not designed for chopping other products like bottles or boxes.

- Hopper System:

- Upper Hopper: Used for trimming and foliage, handling materials up to 2.5 cm in diameter. Operators are cautioned not to put hands or arms into the hopper to push material.

- Side Hopper (Chaff Cutter): Designed for larger branches up to 7 cm in diameter. This hopper needs to be assembled and secured with a closure hook.

- Starting Procedures:

- Petrol Engine Version: Involves setting the selector to "I" (Start), grasping the starting knob, pulling the cord to feel compression resistance, releasing the knob, and then giving a sharp tug. The engine should idle for about 1 minute before reaching maximum revs.

- Electric Motor Version: Requires checking mains voltage compatibility, ensuring the power supply cable is connected, and then pressing the start/stop button.

- Tractor/Motor Cultivator Version: Involves ensuring the bio-chopper is correctly hooked up to the PTO before starting.

- Safety Precautions:

- Always read and understand the manual before use.

- Ensure the machine is on a flat, solid surface to prevent overturning.

- Wear protective gloves and goggles.

- Check that all guards are in place before operation.

- Never use the bio-chopper in the rain.

- For internal combustion engine models, avoid use in closed environments due to fume intoxication risk.

- Fuel handling requires extreme caution: refuel in open air, do not smoke, avoid naked flames, and never open the fuel cap or add petrol while the engine is running or hot.

- In case of heavy shock or anomalous function, stop the engine, remove the spark plug hood, and seek expert advice.

- The blades continue to turn for a few seconds after the ignition is switched off.

Maintenance Features:

Regular maintenance is crucial for the safe and efficient operation of the Bio 80. All maintenance operations require the engine/motor to be switched off, ensuring no possibility of accidental functioning. Suitable gloves are obligatory.

- Routine Checks (Beginning of season, Before each job, End of season):

- Engine oil level

- Tightness of screws (casing, hopper, etc.)

- Belt tension and state of wear

- Wear on cutters, blade, and counter-blade

- Hopper rubber protection

- Clean machine

- Wear on bearings and transmission shafts

- Blade Replacement (8.1):

- Remove the side hopper by unscrewing 3 nuts.

- Unscrew retaining screws and remove the upper hopper.

- Insert keys into two apertures to remove the blade.

- Sharpen or replace the blade with an original spare part. Reassemble in reverse order.

- Counter-blade Replacement (8.2):

- Similar to blade replacement: remove side hopper, unscrew retaining screws, remove upper hopper, insert keys into apertures to remove the counter-blade.

- Sharpen or replace with an original spare part. Reassemble in reverse order.

- Note: The blade must be removed before replacing the counter-blade.

- Breaker Bar Removal, Inversion, and Replacement (8.3):

- Remove upper hopper, side hopper, transmission belt casing, and galvanized hole plate.

- Turn the rotor to align the cutter shaft with the aperture.

- Use an Allen key and spanner to unscrew the locking screw and pull out the rod, collecting spacers.

- Replace breaker bars, ensuring spacers are returned to their original position.

- Partial replacement of breaker bars must respect opposite positions for balancing.

- Sieve Replacement (8.4):

- Remove two nuts and detach the sieve from the lever.

- Remove the old sieve and mount the new one, then tighten the nuts.

- The sieve lever can be partially opened for shredding green or wet material.

- Drive Belt Replacement and Tensioning (8.5 & 8.6):

- Remove the belt guard.

- Remove the old belt and mount a new one.

- Petrol Engine Version (8.5): Unscrew 4 motor screws and pull the motor in the direction shown by the arrow to tension the belt. Tighten screws, avoiding over-stretching. Remount guard.

- Motor Cultivator Version (8.6): Unscrew 4 screws securing the motor-cultivator plate and pull the plate in the direction shown by the arrow to tension the belt. Remount guard.

- Electric Motor Version Specifics:

- Regularly check the power supply cable for perfect condition; do not repair damaged cables with insulating tape.

- Use only standardized rubber cable (type 05 RN-F, DIN 57282 / VDE 0282).

- Hook-up plugs must be rubber or rubber-covered.

- Transportation: For transport, the side hopper can be folded inwards by unhooking the closure hook and immobilizing it with a wing nut.

- Storage: Keep all nuts, bolts, and screws perfectly tightened. Promptly replace worn or damaged parts.

- Troubleshooting: The manual provides a detailed troubleshooting guide for common issues such as the bio-chopper not starting, difficult start-up, loss of power, irregular functioning, excessive vibration, drop in output material quality, and material rejection by the hopper. Remedies often involve checking belt tension, pulleys, PTO/gears, cutters, blades, counter-blades, milling chamber for material, sieve for blockages, engine/motor state, and hopper rubber protection.