Tramming the VFD Spindle

What is Tramming and Why Is it Important?

Have you ever seen small tool marks on your projects or found that the audible pitch of the router/spindle

changes significantly when cutting in a certain direction? If you are nodding to either of these, then you may

need to tram your machine.

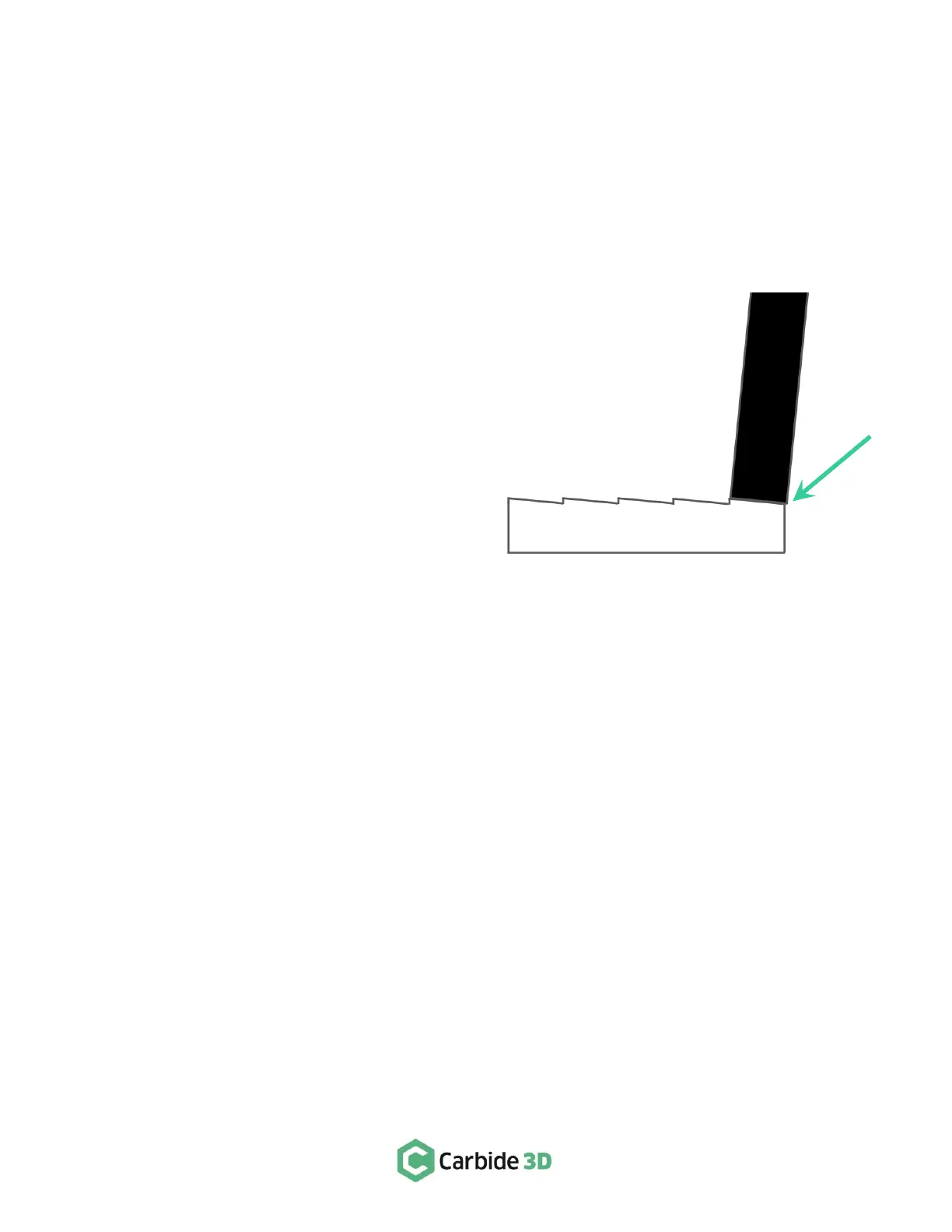

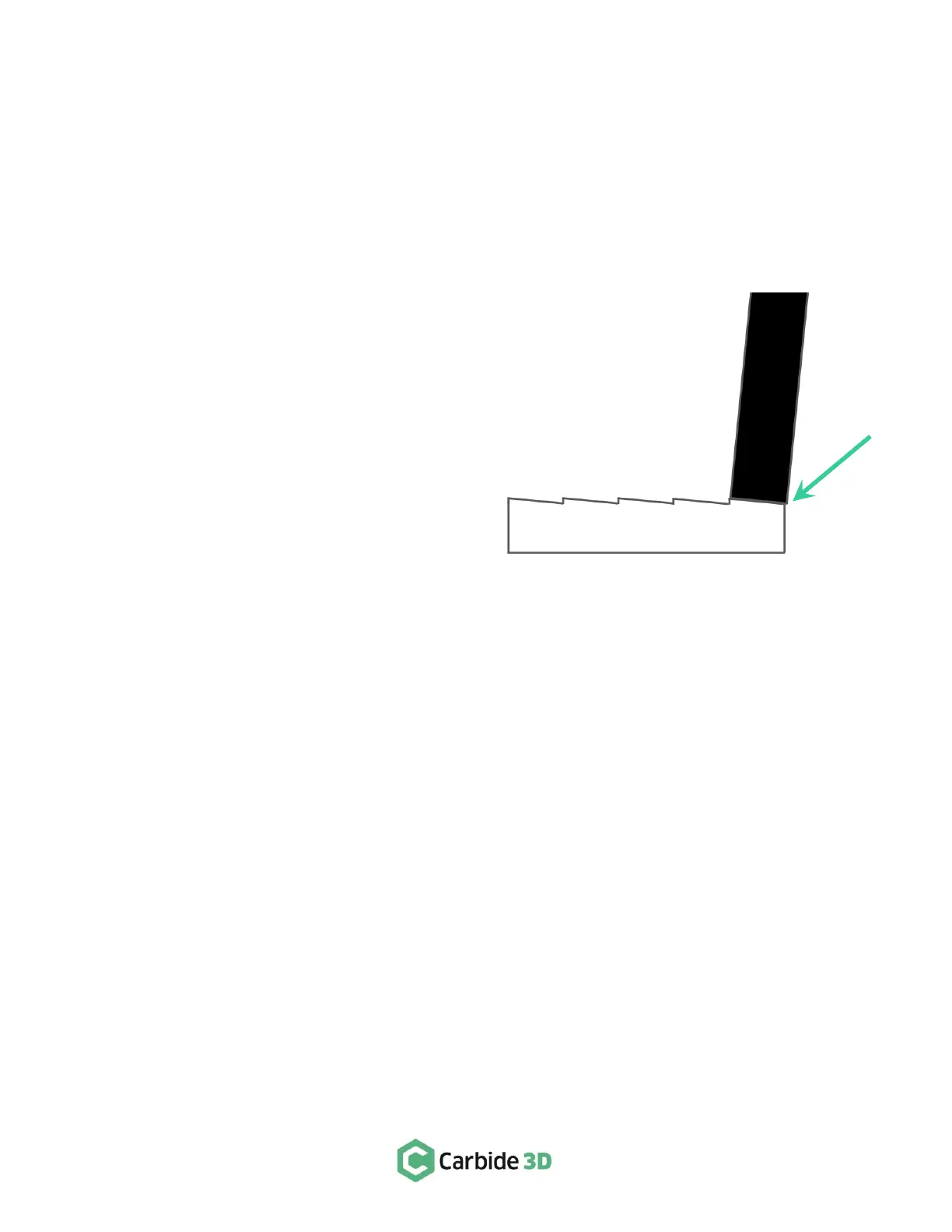

As the end mill travels along the X/Y axis, the actual tip

of the end mill should be parallel to the machine bed.

When the bottom of the end mill is not parallel, the

lowest edge of the end mill becomes the deepest part of

the cut (Fig. 15 shows an exaggerated view of this).

When this happens, you get the issues described above.

These tool marks are more prevalent in harder materials

like metals or composites than in wood because wood is

softer. They will also be more prominent when using a

larger stepover or a larger end mill.

Tramming isn’t a new ‘thing’, every single CNC

machine—even a $150,000 VMC—will have been

trammed upon setup and regularly thereafter as part of

its maintenance cycle.

Identifying and Defining Tram

Below we will define the two types of tram and look at how you can correct them. To help visualize this, imagine

the end mill is your head.

• Nod: Nod is where the spindle tram is out front-to-back. The spindle is nodding forwards or backwards.

• Yaw: This is where the tram is tilted from side-to-side. The spindle is tilted in a clockwise or

counterclockwise direction.

On the next page is a quick guide to help you identify in which direction the tram is out. The guide shows a birds-

eye view of the surface finish. The red line indicates where the cutter is cutting deepest.

Loading...

Loading...