8555-M512-O1 Rev D 01/15 50

CARE AND CLEANING

NOTE: The MV1 contains no user-serviceable parts and maintenance should be

limited to an occasional cleaning and battery replacement as required.

Do not submerge the MV1 in water, pour or spray water directly on it to clean. The

MV1 is not waterproof and covering it with water will damage it and void the warranty.

Always remove power before cleaning.

Do not use wire brushes, abrasives, or cleaning tools such as steel pads and

scrapers, which will scratch the painted surface. Instead, use soft cloths or plastic

scouring pads for cleaning.

When possible use treated water. Hard water can leave behind deposits. Soft water

is much gentler on the painted steel’s surface.

Avoid the use of acetone, thinner or other volatile solvents and abrasive type

cleaners for cleaning. If required, a mild solvent such as mineral spirits can be used

to remove oil, grease, tars, wax, and similar substances. Use a cloth dampened with

mineral spirits and apply only to areas that are contaminated. Follow up the use of

this mild solvent with detergent cleaning and rinsing.

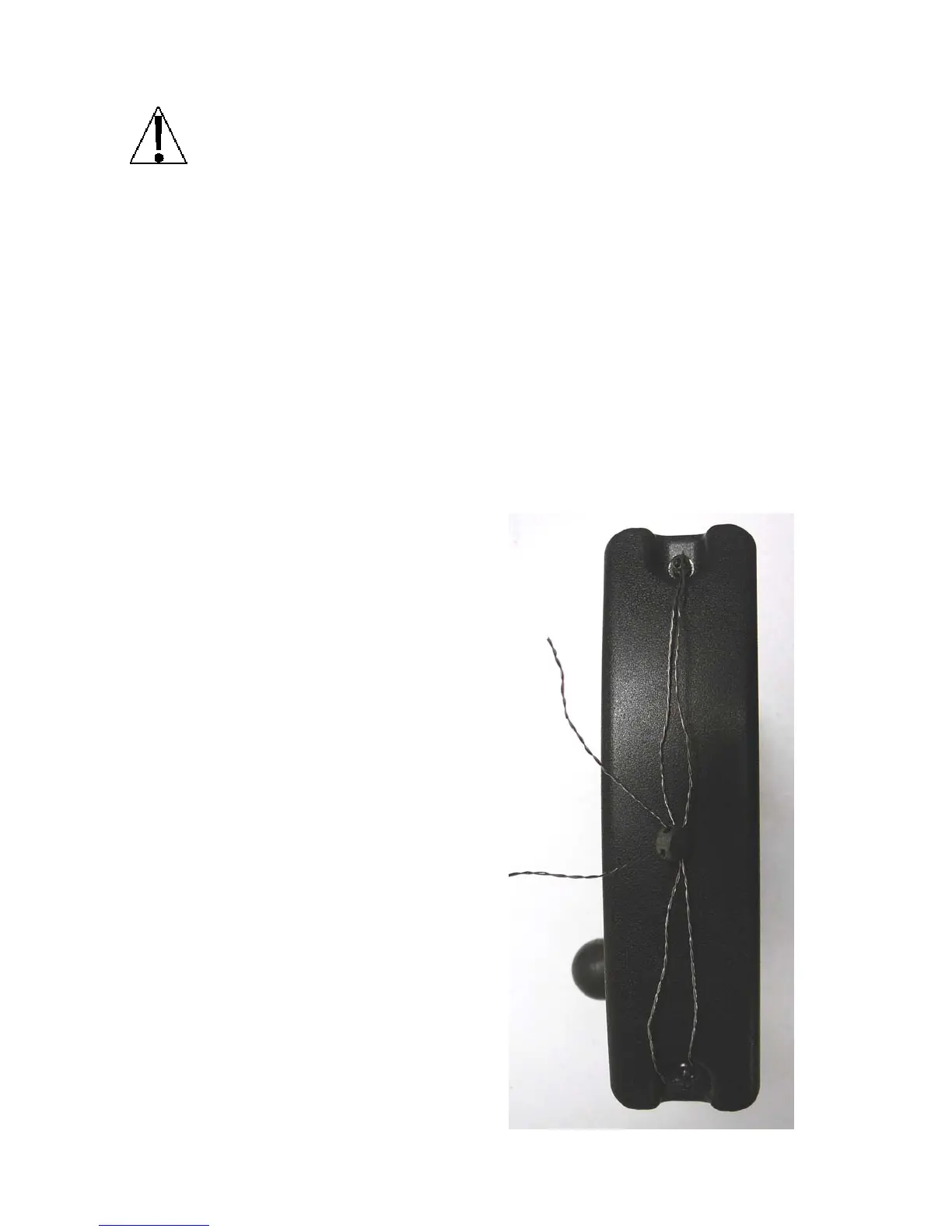

SECURITY SEAL INSTALLATION

If your metrology laws require the use of physical

sealing, a lead and wire security seal can be

installed on the MV1 to prevent the end cap from

being removed from it to gain access to the

calibration switch thereby preventing unauthorized

access to the calibration adjustments.

NOTE: In order to install the lead and wire

security seal, the two screws securing the left end

cap (as viewed from the MV1 front) MUST be

replaced with two drilled screws. They are

available from the Cardinal/Detecto Parts

Department. The part number is MVSK

(MEDVUE SEALING KIT).

To install a lead and wire security seal, refer to

Figure No. 12 and follow the steps provided below:

1. Remove the two screws securing the left end

cap (as viewed from the MV1 front).

2. Install the two drilled screws (and lock

washers) in the end cap making certain they

are securely tighten before proceeding.

3. Thread the sealing wire through the hole in

the drilled screws.

4. Pull the wire tight and install the lead seal.

5. The screws can not be removed without

damaging the seal.

Figure No. 12

Loading...

Loading...