Standard air-conditioning units

Carel Cod. +030221421 – Rel. 1.2 – April, 11, 2003

7

1.5 ELECTRONIC EXPANSION VALVE

The EVDriver module for the control of the electronic expansion valves (EEV) for pLAN network allows the inlet overheating control for a

more efficient and versatile operation of the refrigerating unit.

Efficient because the optimisation and the stabilization of the refrigerant flow to the evaporator increase the performance of the installation

assuring at the same time the safety (less activations of the low pressure switch, less backflows of the refrigerant to the compressor,…).

Moreover, if the EEV has been properly dimensioned, using the floating or low setpoint condensation (and evaporation) pressure increase

remarkably the efficiency of the installation allowing less energy consumption and a better refrigerating yield.

Versatile because using the electronic expansion valve implies the possibility to manage refrigerating units with very different capacities and in

different operating conditions.

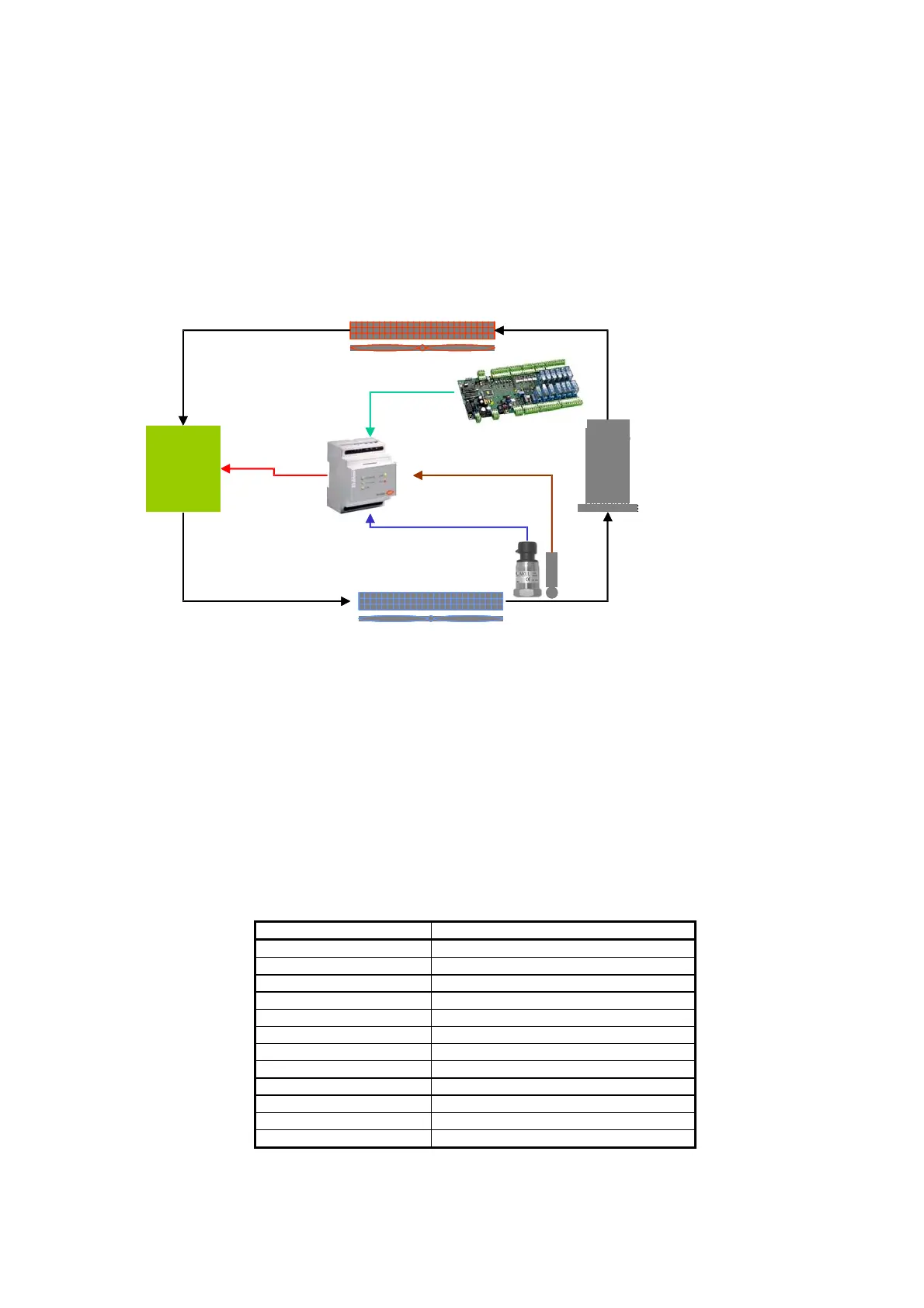

The use of the electronic expansion valve implies the installation not only of the EVDriver or the expansion valve themselves, but also of a

temperature sensor and a pressure transducer, both of them placed at the end of the evaporator on the refrigerant side (on the compressor inlet

pipe). Refer to the following diagram for a better understanding of the typical installation layout.

The base principle of the new control algorithm aims at the installation stability combined with, when possible, a quick achievement of the

overheating steady state.

In this sense, the priorities to be considered for an optimum control of the refrigerating installation are a high and constant refrigerating yield

rather than an extremely low and stable overheating.

The heart of the control is a PID controller that features coefficients that can be set for the overheating.

The additional controls are: LOW (Low overheating with integral time and adjustable threshold)

LOP (Low evaporation pressure, operating actually only on transients, with integral time

and adjustable threshold)

MOP (High evaporation pressure, with integral time and adjustable threshold)

HiTcond (High condensation pressure that can be activated only by condensation pressure

probe read by pCO, with integral time and adjustable threshold).

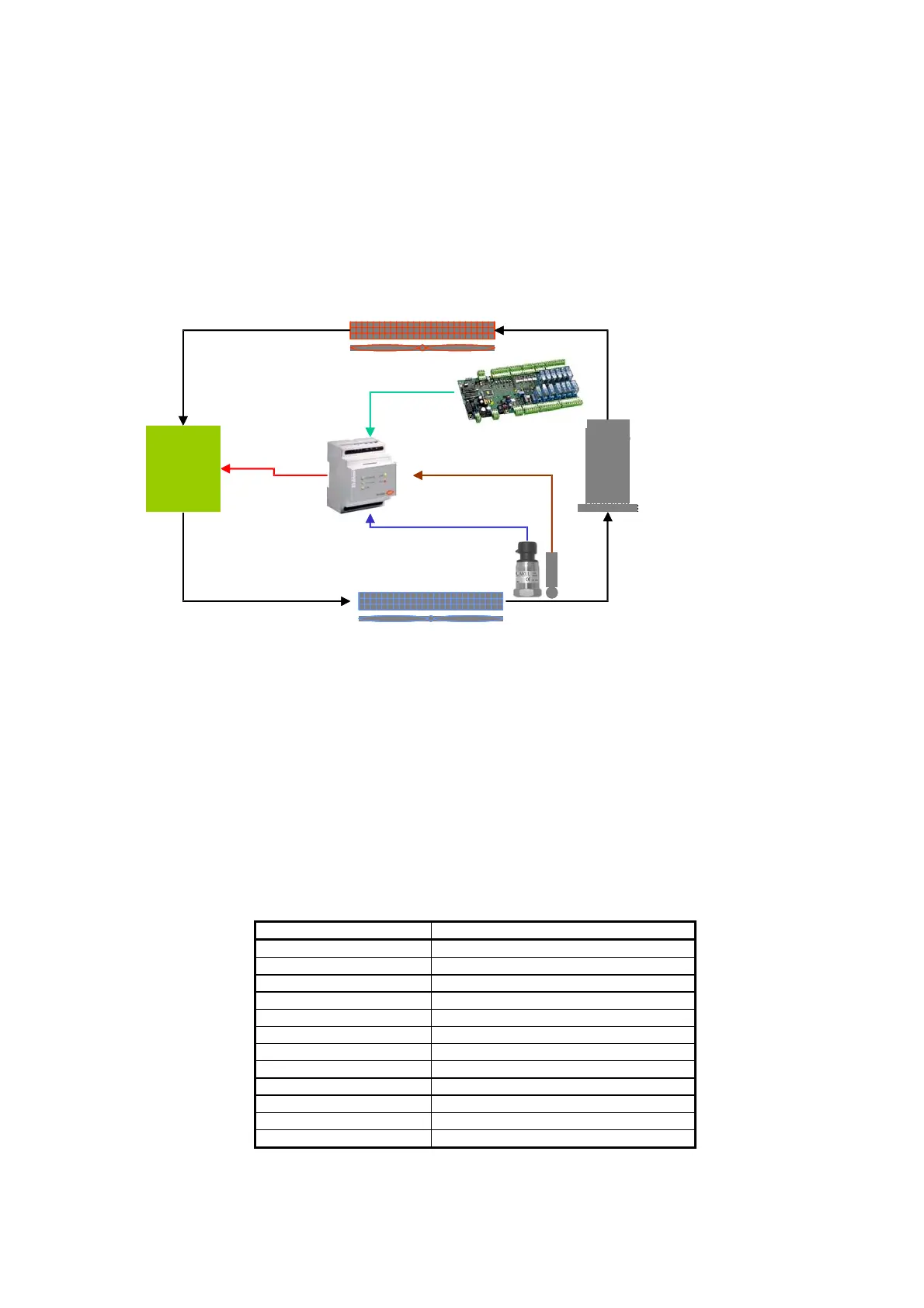

In the parameter table, the control parameters, with the thresholds and the default values, are described. The table below explains the meaning of

the parameter VALVE TYPE (see screens F1 – F2):

PARAMETER VALUE CORRESPONDING VALVE TYPE

0 Alco EX5 – EX6

1 Alco EX7

2 Alco EX8

3 Sporlan SEI 0.5 - 11

4 Sporlan SEN 25

5 Sporlan SEN 50 - 250

6 Danfoss ETS 50

7 Danfoss ETS 100

8 ---

9 Carel E2V**P

10 ---

11 Custom (other valve type)

Condensor

EEV

Evaporator

Compressor

T probe

P probe

Motor

connection

pLAN

EEV

Evaporator

T probe

P probe

Motor

connection

pLAN

Loading...

Loading...