Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

26

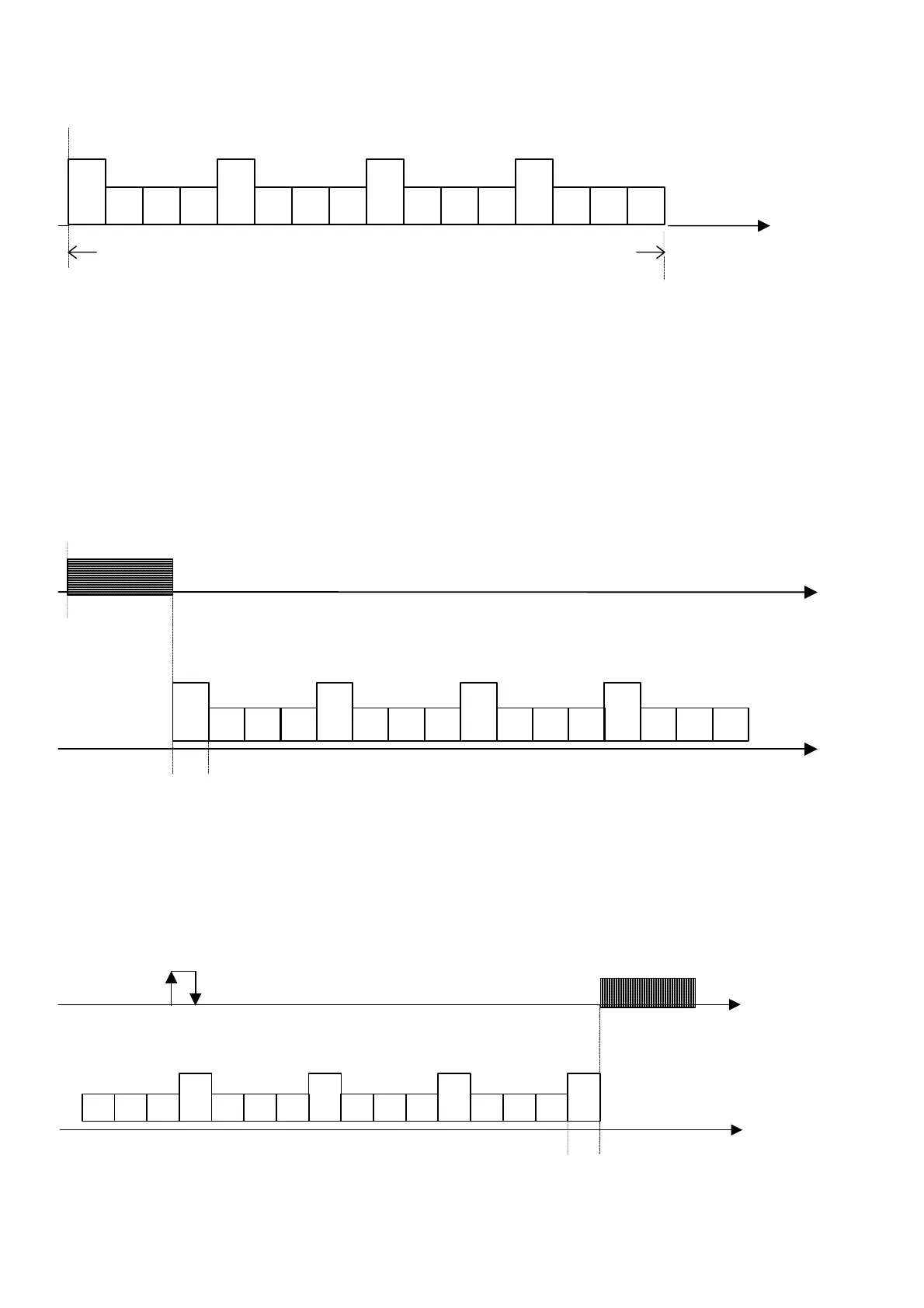

11.2 Stepped capacity control with control at inlet

A description of stepped capacity control of 4 compressors with four capacity control steps each:

Control set point

Evaporator inlet temperature

Control band

C4P1

P2 P3 P4

C1P1

P2 P3 P4

C2P1

P2 P3 P4

C3P1

P2 P3 P4

All compressors and the relevant capacity control steps will be proportionally positioned in the band. Increasing temperature values will cause

the control steps to be subsequently input. Each step will be input according to the set delay times.

The compressors will be started at the first entered capacity control stage. If special management of the first capacity control stage was selected,

control will be effected according to the description in the dedicated section.

In any event, the times for the capacity controls will be applied as described.

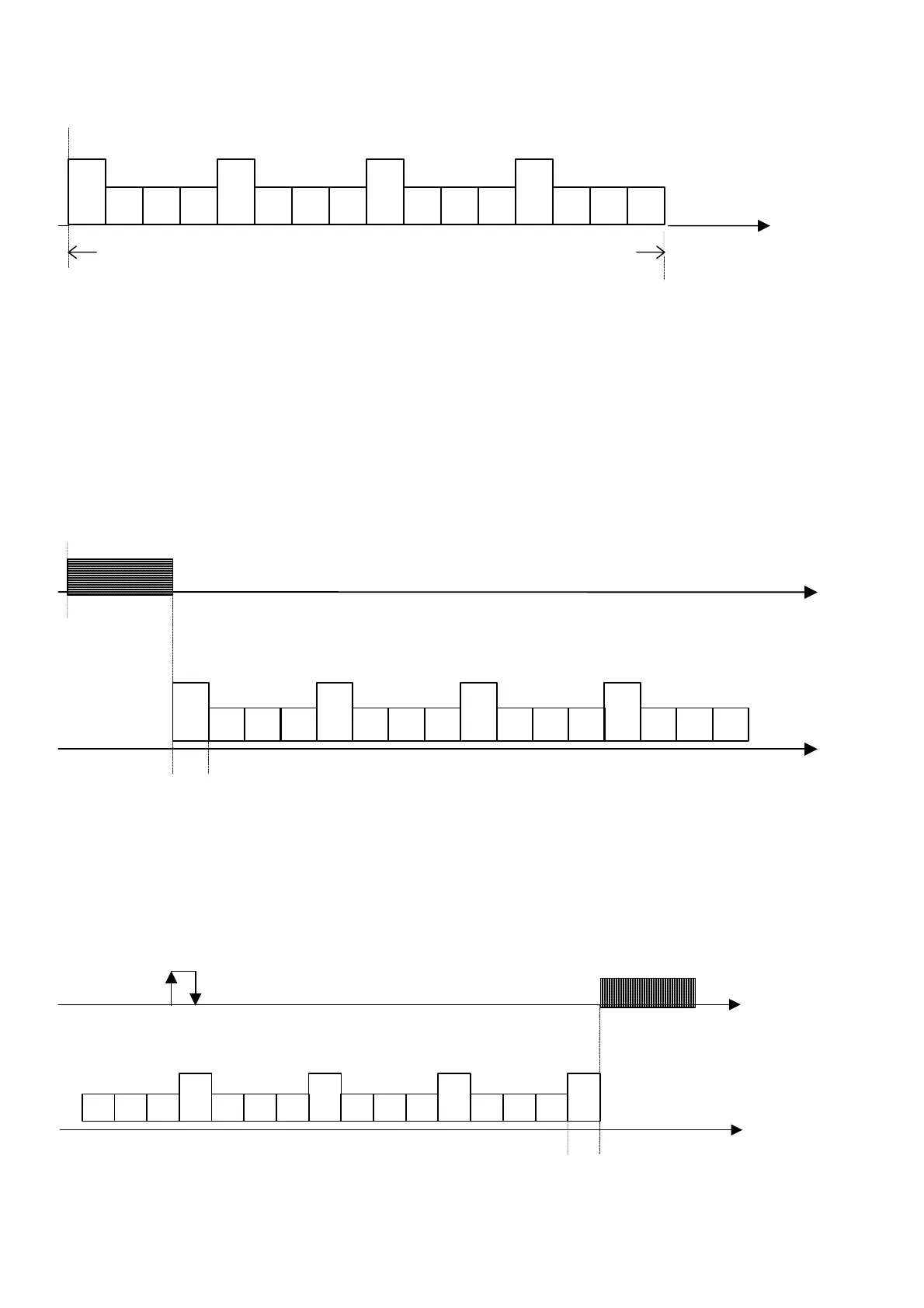

11.3 Stepped capacity control with control at outlet

A description of stepped capacity control of 4 compressors with four capacity control steps each:

11.3.1 Activation of compressors

if the water temperature measured by the probe located at the evaporator outlet exceeds the threshold of Control Set-point + Control Band (Point

B), the number of power stages will be increased - the power stages were input according to the set parameter known as "delay between power-

up of different devices".

Evaporator Outlet Temperature

Point B

Control set point

C4P1

P2 P3 P4

C1P1

P2 P3 P4

C2P1

P2 P3 P4

C3P1

P2 P3 P4

Time [s]

Devices activation delay

The activation delay of the different devices is the same, without distinction of compressors and capacity control steps.

The activation delay times for the capacity controls are considered only if the step activation delay is shorter than the set delays. In this way, the

power increase speed of the compressor is reduced. If the difference between the times is too high, if there is a powered up, but not fully loaded

compressor, the next compressor could be started.

11.3.2 Power-down of compressors

If the water temperature measured by the probe located at the evaporator outlet is below the Control Set-point (Point A), the number of power stages

will be reduced - power stages were input according to the set parameter known as "delay between power-downs of different devices".

Delayed disablement of devices

Forced power-down

threshold

Evaporator outlet temperature

Point A

control set

point

C4P1

P2

P3

P4

C1P1

P2P3P4

C2P1

P2P3P4

C3P1

P2

P3

P4

Time [s]

If temperature falls below the set forced power-down threshold, the compressors are powered down irrespective of the set delays, in order to

prevent tripping the antifreeze alarm.

Loading...

Loading...