Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

34

18 Defrosting control for water/air machines

Inputs used:

• battery B3 temperature (can be used as a pressure switch)

• high pressure B7

• Input for defrosting pressure switch 1

Parameters used :

• Inputs used for defrosting

• Type of defrosting (simultaneous / separate/independent)

• Type of defrosting start and finish (compressor behaviour)

• defrosting start set point

• defrosting stop set point

• Defrosting delay time

• Maximum defrosting time

• Type of compressor operation during the refrigerating cycle reversing stage.

• Drip-off time

Outputs used :

• Compressor 1

• Cycle reversing solenoid-valve 1

• Fan.

18.1 Types of defrosting

18.1.1 Simultaneous

Only one circuit has to request entering the defrosting cycle for all circuits to forcibly enter defrosting. Circuits which do not need to defrost (temperature

above defrosting stop set-point) stop and wait. As soon as all circuits finish defrosting, the compressors may restart on heat pump operation.

18.1.2 Separate

The first pCO unit requesting defrosting begins to defrost, the other units - even if they request defrosting - wait (the heat pump continues to

operate) until the first one finishes defrosting. All the units sequentially complete their defrosting cycle.

18.1.3 Independent

The units can start defrosting at random, independently of each other. In this way, there may be several machine starting to defrost

simultaneously.

18.2 Type of defrosting start/end

Defrosting management can be controlled either by battery B3 temperature probe, or by the B7 high pressure probe. The user can select one of

the two probes from the screen.

The compressor can have four different types of behaviour in connection with start/end of defrosting. This makes it possible to protect the

compressor against sudden cycle reversing, if necessary. Times are not considered in these compressor power-downs and power-ups.

• None: The refrigerating cycle is reversed at inlet/outlet to/from the defrosting cycle occurs with the compressor ON.

• Start of defrosting: The compressor is powered down by the reversal of the refrigerating cycle only at the inlet of the defrosting cycle.

• End of Defrosting: The compressor is powered down by the reversal of the refrigerating cycle only at the outlet from the defrosting cycle.

• Start/end of defrosting: The compressor is powered down by the reversal of the refrigerating cycle both at the inlet and outlet to/from the defrosting cycle.

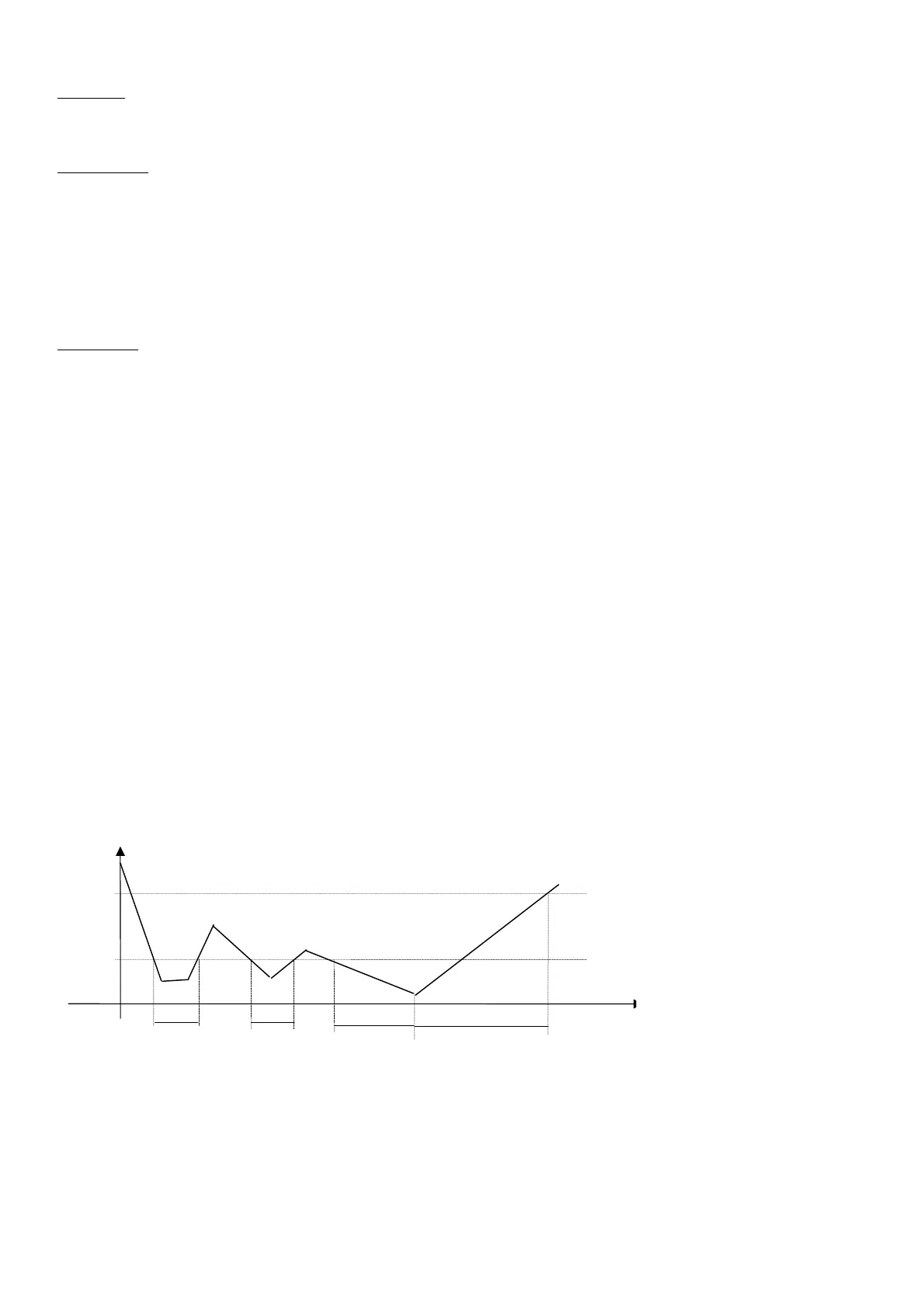

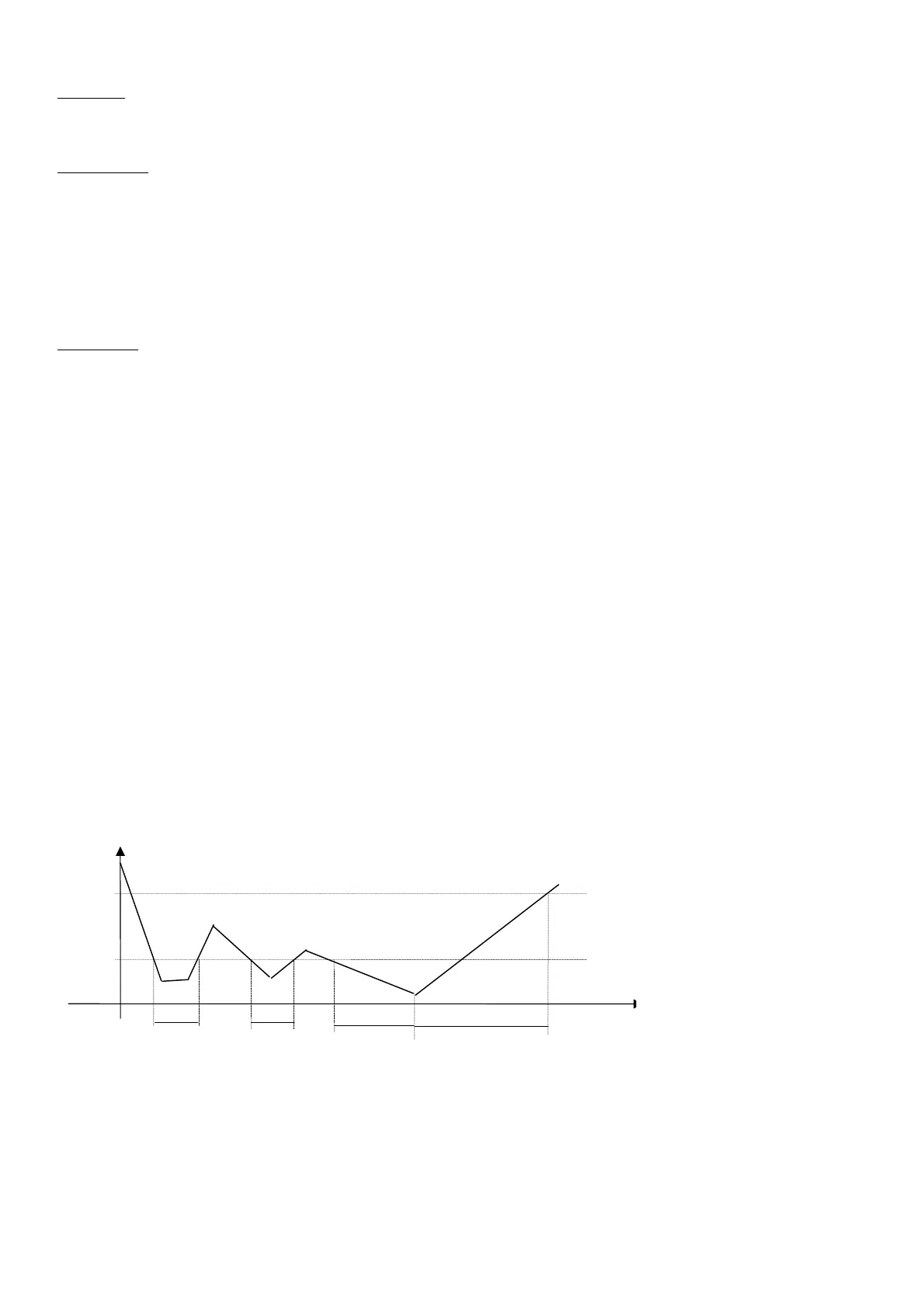

18.3 Defrosting a circuit with time/temperature control

If the battery temperature/pressure

remains below the defrosting start

set point for a cumulative time equal

to defrosting delay time, the circuit

in question enters a defrosting cycle.

• the system's refrigerating

capacity reaches maximum

value

• the refrigerating circuit is

reversed with the 4-way valve

• the fan in question goes OFF (if

pressure probes are present)

The circuit leaves the defrosting cycle due to temperature/pressure (if battery temperature exceeds the defrosting stop set point) or due to

maximum time if the defrosting cycle exceeds the set maximum time threshold.

18.4 Defrosting a circuit with time/pressure switches control

control is exactly the same, with the difference that the status of the pressure switches is counted rather than temperature/pressure.

18.5 Operation of fans during the defrosting stage

The fans are usually OFF during the defrosting cycle. They are activated only if the pressure probes were enabled and pressure exceeds the

prevent threshold - in this way the unit is prevented from going into high pressure alarm status.

Temperature

Time [s]

t1 t2

t3

Defrosting cycle

Set.start

Set.stop

Loading...

Loading...