What to do if my Carrier Air Conditioner shows a Fuse Blown Alarm?

- VveronicaadkinsJul 30, 2025

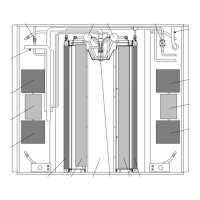

If your Carrier Air Conditioner displays a Fuse Blown Alarm, the issue might stem from defective wiring, a faulty coach power source, or a blown internal microprocessor fuse. You should repair or replace any defective wiring or the power source. Additionally, replace the blown fuse.