4-1 T -312

SECTION 4

SERVICE

W ARNING

BE SURE TO OBSERVE WARNINGS LISTED IN THE SAFETY SUMMARY IN THE FRONT OF THIS

MANUAL BEFORE PERFORMING MAINTENANCE ON THE HVAC SYSTEM

NOTE

Following completion of all maintenance or service activities, the alarm queue should be cleared of any

original alarms and any alarms generated during service. Refer to paragraph 2.1.6

4.1 MAINTENANCE SCHEDULE

SYSTEM

REFERENCE

ON OFF

paragraph

a. Daily Maintenance

X

X

Pre-trip Inspection -- after starting

Check tension and condition of V -belt

2.2

None

b. Weekly Inspection

X

X

X

X

Perform daily inspection

Check condenser, evaporator coils and air filters for cleanliness

Check refrigerant hoses and compressor shaft seal for leaks

Feel filter-drier for excessive temperature drop across drier

4.1.a

None

4.5

4.10

c. Monthly Inspection and Maintenance

X

X

X

X

X

X

Perform weekly inspection and maintenance

Clean evaporator drain pans and hoses

Check wire harnesses for chafing and loose terminals

Check fan motor bearings

Check compressor mounting bolts for tightness

Check fan motor brushes

4.1.b

None

Replace/Tighten

None

None

4.19, 4.23

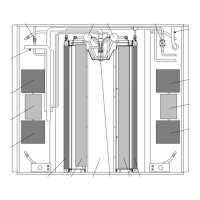

4.2 SUCTION AND DISCHARGE SERVICE

VALVES

The suction and discharge service valves (See

Figure 4-1) used on the compressor are equipped with

mating flanges for connection to flanges on the

compressor. These valves are provided with a double

seat and a gauge connection, which allows servicing of

the compressor and refrigerant lines.

T urning the valve stem counterclockwise (all the way

out) will backseat the valve to open the suction or

discharge line to the compressor and close off the

gauge connection. In normal operation, the valve is

backseated to allow full flow through the valve. The

valve should always be backseated when connecting

the service manifold gauge lines to the gauge ports.

T urning the valve stem clockwise (all the way forward)

will frontseat the valve to close off the suction or

discharge line to isolate the compressor and open the

gauge connection.

To measure suction or discharge pressure, midseat the

valve by opening the valve clockwise 1/4 to 1/2 turn.

With the valve stem midway between frontseated and

backseated positions, the suction or discharge line is

open to both the compressor and the gauge connection.

VALVE STEM CAP

VALVE

STEM

TO DISCHARGE OR

FROM SUCTION LINE

PORT TO

COMPRESSOR

Service Valve

Frontseated

(clockwise)

Service Valve

Backseated

(counterclockwise)

ACCESS VALVE

(R-134a)

ACCESS VALVE CAP

Figure 4-1. Suction or Discharge Service Valve

Loading...

Loading...