4-12T -312

b. Use a digital volt-ohmmeter to measure voltage

across the transducer and compare to values in

Table 4-5. A reading within two percent of the values

in the table would be considered good.

Table 4-5. Suction and Discharge Pressure

T ransducer (SPT and DPT) Voltage

Psig Voltage Psig Voltage Psig Voltage

20” 0.369 105 1.495 220 2.622

10” 0.417 110 1.544 225 2.671

0 0.466 115 1.593 230 2.720

5 0.515 120 1.642 235 2.769

10 0.564 125 1.691 240 2.818

15 0.614 130 1.740 245 2.867

20

0.663 135 1.789 250 2.916

25 0.712 140 1.838 255 2.965

30 0.761 145 1.887 260 3.014

35 0.810 150 1.936 265 3.063

40 0.858 155 1.985 270 3.112

45 0.907 160 2.034 275 3.161

50 0.956 165 2.083 280 3.210

55 1.007 170 2.132 285 3.259

60 1.054 175 2.181 290 3.308

65 1.103 180 2.230 295 3.357

70 1.152 185 2.279 300 3.406

75 1.204 190 2.328 305 3.455

80 1.250 195 2.377 310 3.504

85 1.299 200 2.426 315 3.553

90 1.348 205 2.475 320 3.602

95 1.397 210 2.524 325 3.651

100 1.446 215 2.573 330 3.700

4.16 REPLACING SENSORS AND

TRANSDUCERS

a. T urn main battery disconnect switch to OFF position

and lock.

b. Tag and disconnect wiring from defective sensor or

transducer.

c. Remove and replace defective sensor or transducer .

d. Connect wiring to replacement sensor or transducer .

e. Checkout replacement sensor or transducer. (Refer

to paragraph 4.13, 4.15 or 4.14, as applicable.)

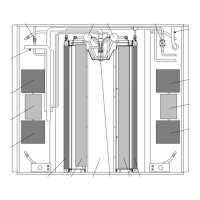

4.17 SERVICING MAIN EVAPORATOR BLOWER

ASSEMBLY

a. T urn main battery disconnect switch to OFF position

and lock.

b. Remove access door located in the #3 baggage

compartment. To remove the access door, unlatch,

then open the door enough to slide the hinge pins out

of the pin brackets.

c. Disconnect electrical connections to the motor.

d. Remove blower transitions ducts.

e. Remove the four bolts securing the evaporator motor

mounting plate, motor and blower housing assembly

to the bottom panel.

f. Remove motor and blower wheel assembly by sliding

out of evaporator housing.

g. Repair or replace any defective component(s), as

required.

h. Replace by reversing steps b. thru f.

4.18 ACCESSING MAIN EVAPORATOR MOTOR

BRUSHES

a. T urn main battery disconnect switch to OFF position

and lock.

b. Remove access door. (Refer to 4.17.b.)

c. Disconnect electrical connections to the motor.

d. With a marker, trace the outline of the motor on the

motor plate.

e. Remove the four brush access doors on the motor .

f. Service two brushes (top front and top rear).

g. Remove the four bolts securing the evaporator motor

to the mounting plate.

h. Rotate the motor to gain access to the lower front

brush.

i. Rotate the motor the opposite way to gain access to

the lower rear brush.

j. Rotate the motor back to its feet and position back to

its original position guided by the outline drawn in step

d.

k. Re--secure the motor with the four bolts removed in

step g. Check fan rotation, insuring that the fan

wheels do not make contact with the fan housings.

l. Complete the procedure by performing steps a. thru

c. in reverse.

4.19 SERVICING MOTOR BRUSHES

If the brushes are broken, cracked, severely chipped, or

worn to 1/3 their original length, replace them.

a. Remove the four brush access doors on the motor .

b. With fingers or a suitable hook, lift the brush spring

end up so the brush may slide up and out of the

holder. Loosen the brush screw to remove the brush

shunt terminal. Remove the brush.

c. To replace, lift the brush spring and place the brush in

the holder . Position the end of the spring on top of the

brush.

d. Connect the brush shunt terminal to its proper

crossover with the brush screw assembled loosely.

NOTE

Assure positioning of the brush to permit the

brush shunt to travel freely in the holder slot

as the brush wears. If the brush hangs up,

commutator damage and motor failure will

result

e. T ighten screw.

Loading...

Loading...