4-7 T -312

e. If gauge reading is 3 psig (.2 BAR) or higher than the

calculated P/T pressure in step d, noncondensibles

are present.

f. Remove refrigerant using a refrigerant recovery

system. (Refer to paragraph 4.6.3)

g. Evacuate and dehydrate the system. (Refer to

paragraph 4.6)

h. Charge the unit. (Refer to paragraph 4.7)

4.9 CHECKING AND REPLACING HIGH

PRESSURE CUTOUT SWITCH

4.9.1 Replacing High Pressure Switch

a. The high pressure switch is equipped with schrader

valve to allow removal and installation without

pumping the unit down.

b. Unplug the wiring from the switch.

c. Check switch operation. (Refer to paragraph 4.9.2)

d. Replace switch if it does not function as outlined

below. (Refer to paragraph 4.9.2)

4.9.2 Checking High Pressure Switch

W ARNING

DO NOT USE A NITROGEN CYLINDER

WIT HO UT A PRESSURE REGULATOR

DO NOT USE OXYGEN IN OR NEAR A

REFRIGERATION SYSTEM AS AN

EXPLOSION MAY OCCUR.

a. Remove switch from unit. All units are equipped with

schrader valves at the high pressure switch

connection.

b. Connect an ohmmeter across switch terminals. If the

switch is good, the ohmmeter will indicate continuity,

indicating that the contacts are closed.

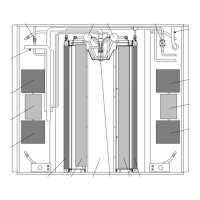

1. Cylinder Valve

and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge,

0 to 400 psig

(0 to 2.8 mPa)

5. Bleed-Off Valve

6. 1/4 inch Connection

1

2

3

4

5

6

Figure 4-5. Checking High Pressure Switch

c. Connect switch to a cylinder of dry nitrogen. (See

Figure 4-5)

d. Set nitrogen pressure regulator higher than cutout

point on switch being tested. (Refer to paragraph 1.3)

e. Open cylinder valve. Slowly open the regulator valve

to increase the pressure until it reaches cutout point.

The switch should open, which is indicated by an

infinity reading on an ohmmeter (no continuity).

f. Close cylinder valve and release pressure through

the bleed-off valve. As pressure drops to cut-in point,

the switch contacts should close, indicating continuity

on the ohmmeter.

4.10 FILTER-DRIER

4.10.1.T o Check Filter Drier

Check for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the

filter-drier . If the outlet side feels cooler than the inlet

side, then the filter-drier should be changed.

4.10.2.T o Replace Filter Drier

a. Pump down the unit. (Refer to paragraph 4.4)

b. Replace filter-drier, ensuring that the arrow points in

the direction of the refrigerant flow.

c. Drier can be evacuated at liquid line service valve.

(See Figure 4-4)

d. Check refrigerant charge. (Refer to paragraph 4.7.1)

1. Power Head Assembly

2. Equalizer Connection

3. Bulb

4. Cage Assembly

5. Seat Gasket

6. Body Flange

7. Capscrew

8. Body Flange Gasket

1

2

3

4

5

6

7

8

Figure 4-6. Thermostatic Expansion Valve

4.11 THERMOSTATIC EXPANSION VALVE

The thermostatic expansion valve (TXV) is an

automatic device which maintains constant superheat

of the refrigerant gas leaving the evaporator regardless

of suction pressure. The valve functions are: (a)

automatic response of refrigerant flow to match the

evaporator load and (b) prevention of liquid refrigerant

returning to the compressor. Unless the valve is

defective, it seldom requires any maintenance. All

TXV’s are non--adjustable.

4.1 1.1 Replacing the Expansion Valve (See

Figure 4-6)

a. Pump down low side of the unit. (Refer to paragraph

4.4)

b. Remove insulation (Presstite) from expansion valve

bulb.

Loading...

Loading...