4-3 T -312

d. Frontseat the liquid line (King) valve by turning

clockwise. Start system and run in cooling. Stop the

unit when the suction pressure reaches 1 psig (0.07

BAR).

e. Frontseat (close) suction service valve to trap the

refrigerant in the high side of the system between the

compressor suction service valve and the filter drier

inlet valve. The low side of the system will now be at 1

psig (0.07 BAR) pressure and ready for servicing,

f. Service or replace the necessary component on the

low side of the system.

g. Leak check connections. (Refer to paragraph 4.5)

h. Evacuate and dehydrate the low side. (Refer to

paragraph 4.6)

i. Reconnect the suction pressure transducer (SPT).

j. Clear the low pressure alarm. (Refer to paragraph

2.1.6)

4.4.2 Removing the Refrigerant Charge

Connect a refrigerant recovery system to the unit at the

condenser service (King) valve to remove refrigerant

charge. (See Figure 4-4) Refer to instructions provided

by the manufacturer of the refrigerant recovery system.

NOTE

1. Before opening up any part of the

system, a slight positive pressure should

be indicated on the gauge.

2. When opening up the refrigerant system,

certain parts may frost. Allow the part to

warm to ambient temperature before

dismantling; this avoids internal

condensation, which puts moisture into

the system.

3. When opening or closing the service

valves, care should be given to note if the

packing around the valve stem is worn or

may need adjustment to prevent

refrigerant leaks.

4.4.3 Refrigerant Removal From An Inoperative

Compressor.

To remove the refrigerant from a compressor that is not

operational, do the following:

a. Attach a manifold gauge set as shown in Figure 4-3

and isolate the compressor by front seating the

suction and discharge valves.

b. Recover refrigerant with a refrigerant reclaimer . If the

discharge service valve port is not accessible, it will

be necessary to recover refrigerant through the

suction service valve port only.

c. Service or replace components as required and leak

check t he compressor.

d. Using refrigerant hoses designed for vacuum service,

connect a vacuum pump to center connection of

manifold gauge set. Evacuate compressor to 500

microns. Close off pump valve, isolate vacuum gauge

and stop pump. Wait 5 minutes to verify that vacuum

holds.

e. Once vacuum is maintained, recharge low side with

R-134a to 20 to 30 PSIG by admitting vapor from the

refrigerant cylinder. Backseat compressor service

valves and disconnect manifold gauge set.

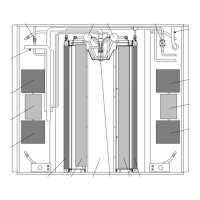

DS

1. Discharge Service

Valve and Port

2. Suction Service

Valve and Port

3. Manifold Gauge

Set

4. Vacuum Pump

5. Reclaimer

6. Refrigerant Cylinder

7. Thermistor Vacuum

Gauge

1

7

6

5

4

3

2

Figure 4-3. Compressor Service Connections

4.4.4 Pump Down An Operable Compressor For

Repair

To service an operable compressor , pump the

refrigerant into the condenser coil as follows:

a. Install manifold gauge set. (See Figure 4-3)

b. Unplug the suction pressure transducer (SPT).

c. Frontseat the compressor suction service valve by

turning clockwise.

d. Start the unit and run in cooling until 10 ”/hg (0.69

BAR) of vacuum is reached. Shut the system down

and tag out system power source.

e. Frontseat the compressor discharge service valve

and wait 5 minutes to verify vacuum is maintained. If

the pressure rises above vacuum, open the

compressor discharge service valve and repeat steps

c and d until a vacuum is maintained.

f. Service or replace components as required and leak

check t he compressor.

g. Using refrigerant hoses designed for vacuum service,

connect a vacuum pump to center connection of

manifold gauge set. Evacuate system to 500

microns. Close off pump valve, isolate vacuum gauge

and stop pump. Wait 5 minutes to verify that vacuum

holds.

h. Once vacuum is maintained, backseat compressor

service valves and disconnect manifold gauge set.

i. Reconnect the suction pressure transducer (SPT).

j. Clear the low pressure alarm. (Refer to paragraph

2.1.6)

Loading...

Loading...