31

Loss-of-Cooler Flow Protection

A proof-of-cooler flow device is factory installed in all chillers. It

is recommended that proper operation of the switch be verified on

a regular basis.

Electronic Expansion Valves (EXVs)

All units are equipped from the factory with EXVs. Each refriger-

ation circuit is also supplied with a factory-installed liquid line fil-

ter drier and sight glass.

The EXV is set at the factory to maintain 9°F (5.0°C) suction su-

perheat leaving the cooler by metering the proper amount of re-

frigerant into the cooler. The superheat set point is adjustable, but

should not be adjusted unless absolutely necessary.

The EXV is designed to limit the cooler saturated suction

temperature to 50°F (12.8°C). This makes it possible for unit to

start at high cooler fluid temperatures without overloading the

compressor.

Capacity Control

The control system cycles compressors, digital scroll modulating

solenoid (if equipped), and minimum load valve solenoids (if

equipped) to maintain the user-configured leaving chilled fluid

temperature set point. Entering fluid temperature is used by the

main base board (MBB) to determine the temperature drop across

the cooler and is used in determining the optimum time to add or

subtract capacity stages. The chilled fluid temperature set point

can be automatically reset by the return fluid temperature, space,

or outdoor-air temperature reset features. It can also be reset from

an external 4 to 20 mA signal (requires energy management mod-

ule FIOP or accessory).

The standard control has an automatic lead-lag feature built in

which determines the wear factor (combination of starts and run

hours) for each compressor. If all compressors are off and less than

30 minutes has elapsed since the last compressor was turned off,

the wear factor is used to determine which compressor to start

next. If no compressors have been running for more than 30 min-

utes and the leaving fluid temperature is greater than the saturated

condensing temperature, the wear factor is still used to determine

which compressor to start next. If the leaving fluid temperature is

less than the saturated condensing temperature, then the control

will start either compressor A1 or compressor B1 first, depending

on the user-configurable circuit lead-lag value. For units with the

minimum load control valve, the A circuit with the minimum load

valve is always the lead circuit. The A circuit is also always the

lead for units with the digital compressor option. On units with the

digital scroll option, the A1 compressor operates continuously,

providing close leaving chilled water control. For this reason, on/

off cycling of the unit’s compressors is dramatically reduced,

which in turn reduces wear associated with compressor start/stop

cycles.

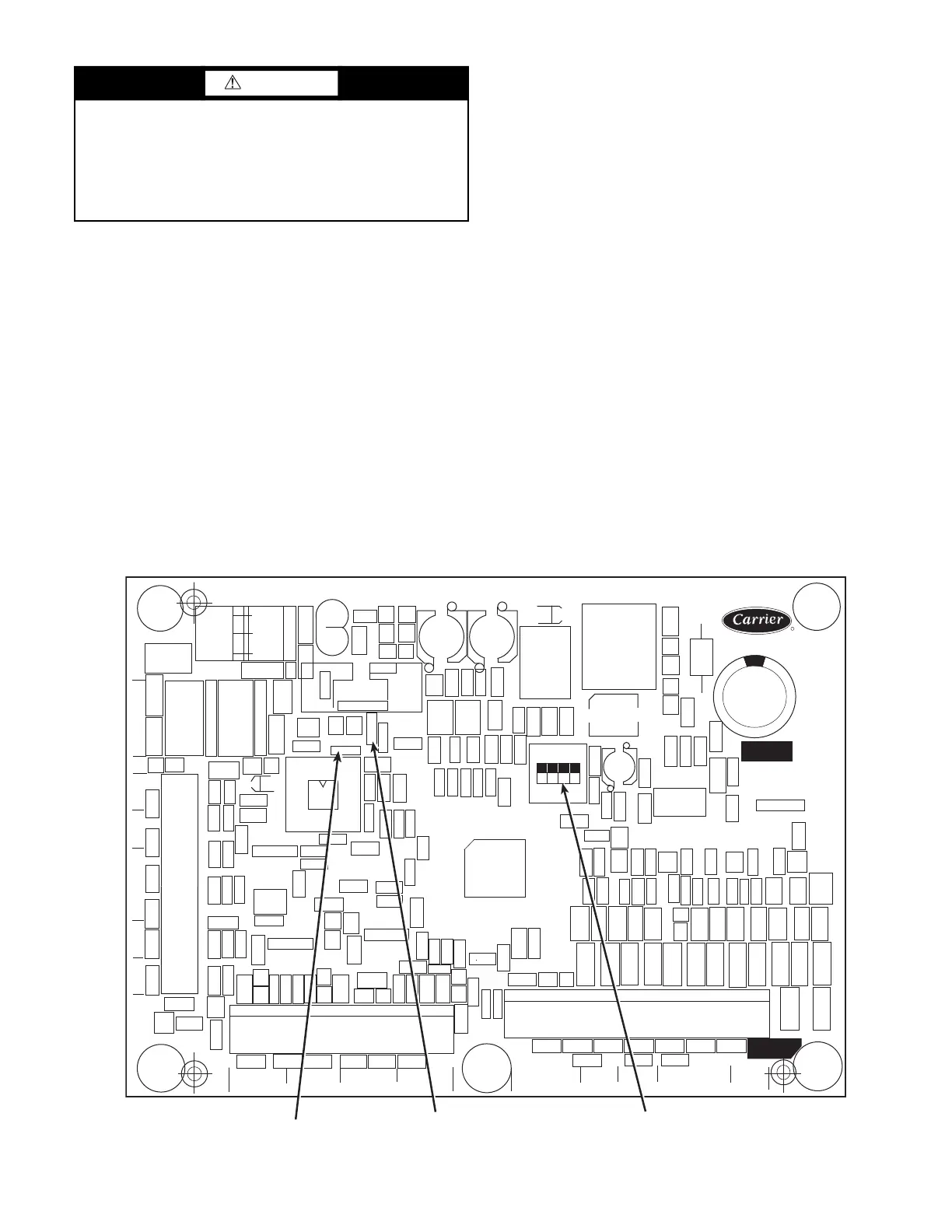

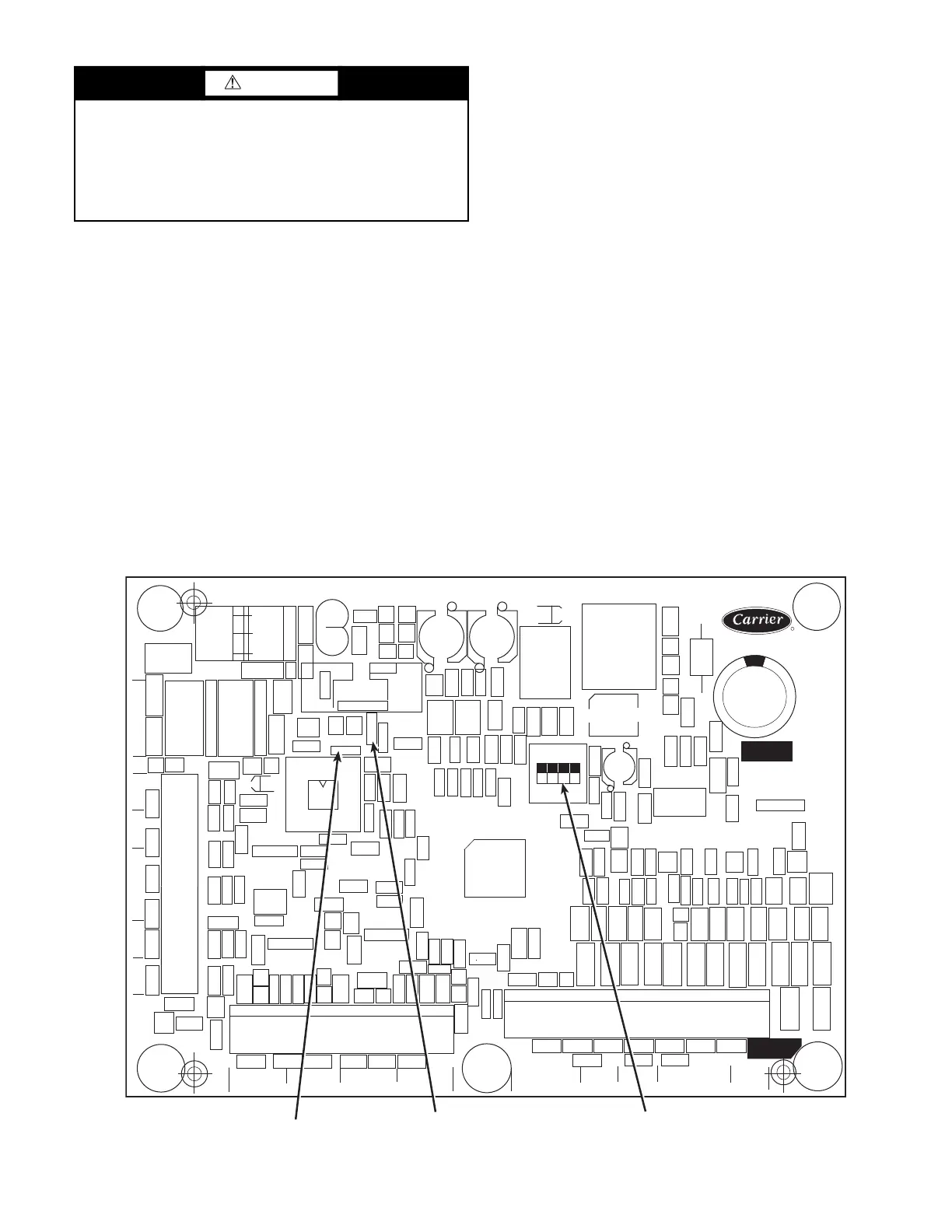

Fig. 26 — Energy Management Module

CAUTION

Care should be taken when interfacing with other manufac-

turer’s control systems due to possible power supply differ-

ences, full wave bridge versus half wave rectification. The two

different power supplies cannot be mixed. ComfortLink con-

trols use half wave rectification. A signal isolation device

should be utilized if a full wave bridge signal generating

device is used.

CEBD430351-0396-01C

TEST 1

CEPL130351-01

PWR

TEST 2

J1

J2

J4 J3

J5

J6

J7

LEN

STATUS

RED LED - STATUS

GREEN LED -

LEN (LOCAL EQUIPMENT NETWORK)

ADDRESS

DIP SWITCH

Loading...

Loading...