67

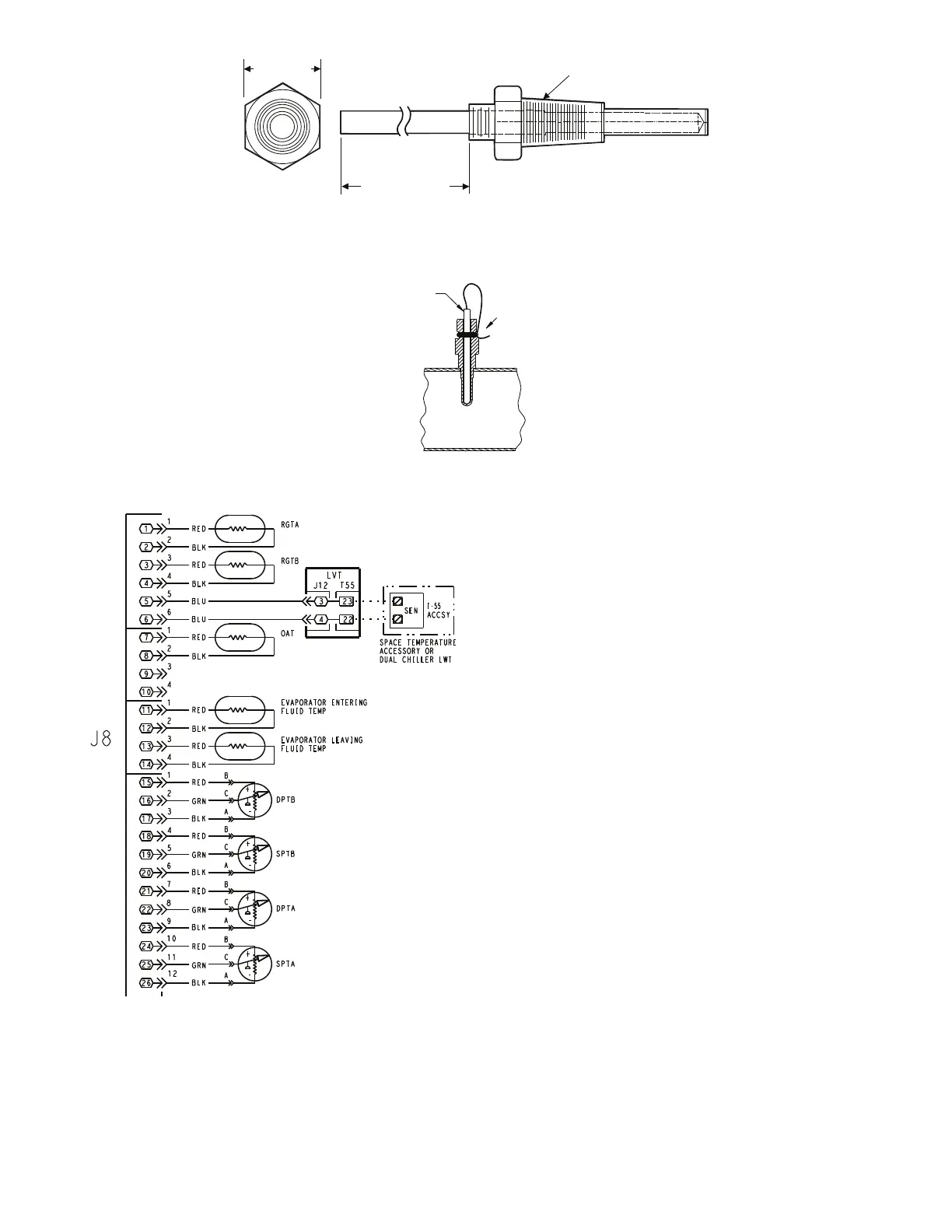

Pressure Transducers

The suction and discharge transducers are different part numbers

and can be distinguished by the color of the transducer body,

suction (yellow) and discharge (red). No pressure transducer

calibration is required. The transducers operate on a 5 vdc supply,

which is generated by the main base board (MBB). See Fig. 51 for

transducer connections to the J8 connector on the MBB.

TROUBLESHOOTING

If a transducer is suspected of being faulty, first check supply volt-

age to the transducer. Supply voltage should be 5 vdc ± 0.2 v. If

supply voltage is correct, compare the pressure reading displayed

on the scrolling marquee display module against pressure shown

on a calibrated pressure gauge. Pressure readings should be within

± 15 psig. If the two readings are not reasonably close, replace the

pressure transducer.

Chilled Water Flow Switch

A factory-installed flow switch is installed in the leaving fluid pip-

ing for all units without the factory-installed hydronic package.

See Fig. 52. Units with the optional hydronic package have the

flow switch installed in the entering fluid piping. This is a thermal-

dispersion flow switch with no field adjustments. The switch is set

for approximately 0.5 ft/sec of flow. The sensor tip houses two

thermistors and a heater element. One thermistor is located in the

sensor tip, closest to the flowing fluid. This thermistor is used to

detect changes in the flow velocity of the liquid. The second

thermistor is bonded to the cylindrical wall and is affected only by

changes in the temperature of the liquid. The thermistors are posi-

tioned to be in close contact with the wall of the sensor probe and,

at the same time, to be kept separated from each other within the

confines of the probe.

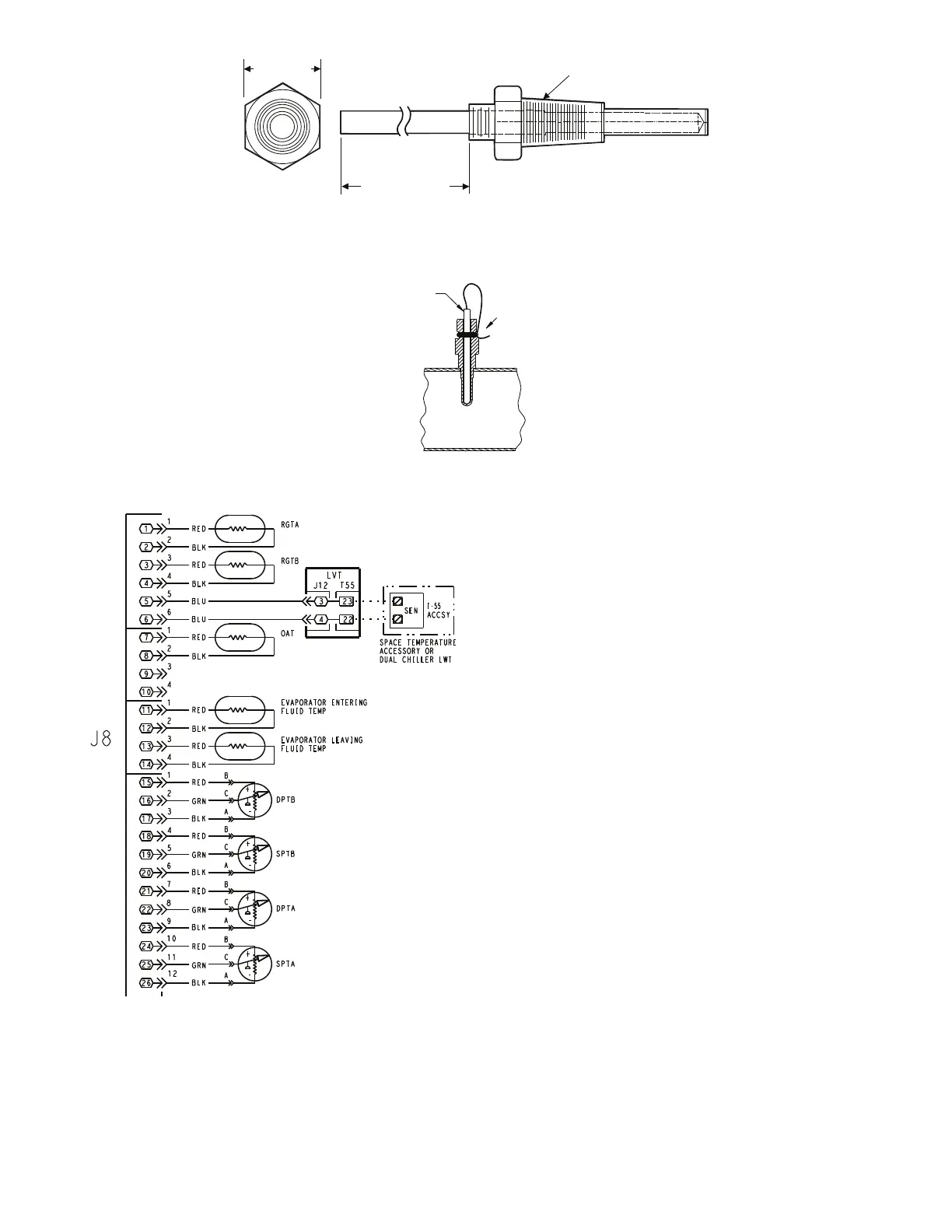

Fig. 50 — Thermistor Well and Return Gas Thermistor (RGT) Mounting

INSTALL NUT AND SEAL

ON THERMISTOR. APPLY

THERMAL CONDUCTIVE

GREASE TO THERMISTOR

AND WELL. INSERT

THERMISTOR INTO WELL.

LOOP WIRE HARNESS AND

SECURE WITH WIRE TIE

TO FORM STRAIN RELIEF.

INSULATE WITH

CORK TAPE

INSULATION.

5/8 in. HEX

6" MINIMUM

CLEARANCE FOR

THERMISTOR

REMOVAL

1/4-18 NPT

26

25

24

23

22

17

16

15

14

13

12

11

10

9

8

7

6

3

1

3

1

3

1

6

2

4

2

4

2

12

11

21

20

19

18

10

9

8

7

6

5

4

5

4

3

2

1

4

2

1

3

5

J8

BLK

RED

LVT

4

3

22

23

T-55

ACCSY

SEN

OAT

BLU

BLU

BLK

RED

RGTB

BLK

RED

RGTA

SPTB

-

+

DPTB

-

+

A

C

B

A

C

B

GRN

RED

BLK

GRN

RED

BLK

SPTA

-

+

DPTA

-

+

A

C

B

A

C

B

GRN

RED

BLK

GRN

RED

BLK

BLK

RED

EVAPORATOR ENTERING

FLUID TEMP

BLK

RED

EVAPORATOR LEAVING

FLUID TEMP

SPACE TEMPERATURE

ACCESSORY OR

DUAL CHILLER LWT

J12 T55

Fig. 51 — Thermistor Connections to

Main Base Board, J8 Connector

LEGEND

ACCSY — Accessory

DPT — Discharge Pressure Transducer

LWT — Leaving Water Temperature Sensor

LVT — Low Voltage Terminal

OAT — Outdoor Air Temperature Sensor

RGT — Return Gas Temperature Sensor

SEN — Sensor Terminal Block

SPT — Space Temperature Sensor

a30-4975

Loading...

Loading...