GH7T: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

2

Installation

Check Equipment and Job Site

IMPORTANT: All split system and packaged heat pumps must be

installed pursuant to applicable regional efficiency standards issued by

the Department of Energy.

Unpack Unit

Move to final location. Remove carton taking care not to damage unit.

Inspect Equipment

File claim with shipping company prior to installation if shipment is

damaged or incomplete. Locate unit rating plate on unit corner panel. It

contains information needed to properly install unit. Check rating plate

to be sure unit matches job specifications.

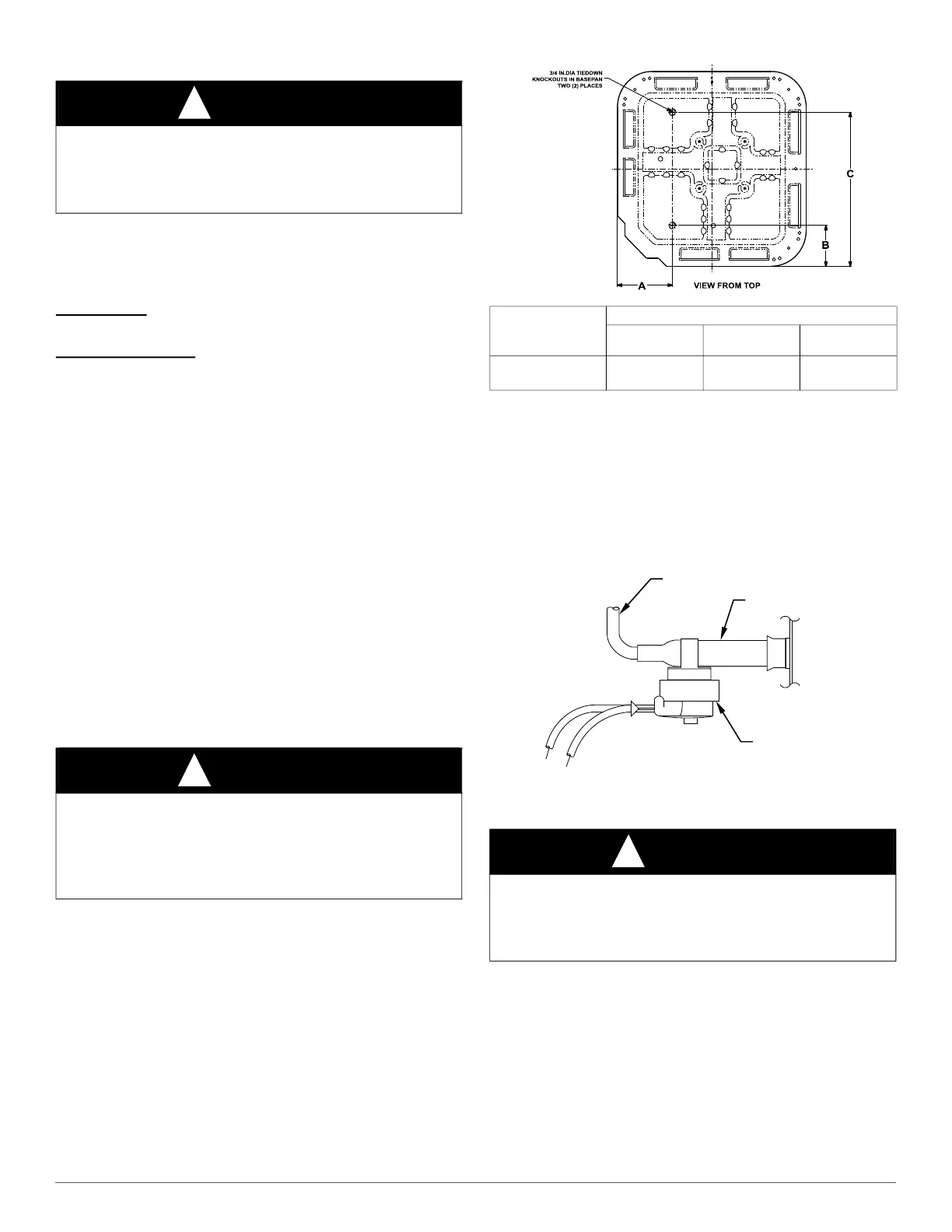

Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad, tie down

bolts should be used and fastened through knockouts provided in unit

base pan. Refer to unit mounting pattern in Fig. 2 to determine base pan

size and knockout hole location.

For hurricane tie downs, contact distributor for details and PE

Certification (Professional Engineer), if required.

On rooftop applications, mount on level platform or frame. Place unit

above a load-bearing wall and isolate unit and tubing set from structure.

Arrange supporting members to adequately support unit and minimize

transmission of vibration to building. Consult local codes governing

rooftop applications.

Roof mounted units exposed to winds above 5 mph (8.05 km/h) may

require wind baffles. Consult the Service Manual - Residential Split

System Air Conditioners and Heat Pumps for wind baffle construction.

NOTE: Unit must be level to within ±2°(±3/8 in./ft,±9.5 mm/m.) per

compressor manufacturer specifications.

Clearance Requirements

When installing, allow sufficient space for airflow clearance, wiring,

refrigerant piping, and service. Allow 24 in. (609.6 mm) clearance to

service end of unit and 48 in. (1219.2 mm) (above unit. For proper

airflow, a 6-in. (152.4 mm) clearance on 1 side of unit and 12-in. (304.8

mm) on all remaining sides must be maintained. Maintain a distance of

24 in. (609.6 mm) between units. Position so water, snow, or ice from

roof or eaves cannot fall directly on unit.

On rooftop applications, locate unit at least 6 in. (152.4 mm) above roof

surface.

A05177

Fig. 2 – Tiedown Knockout Locations

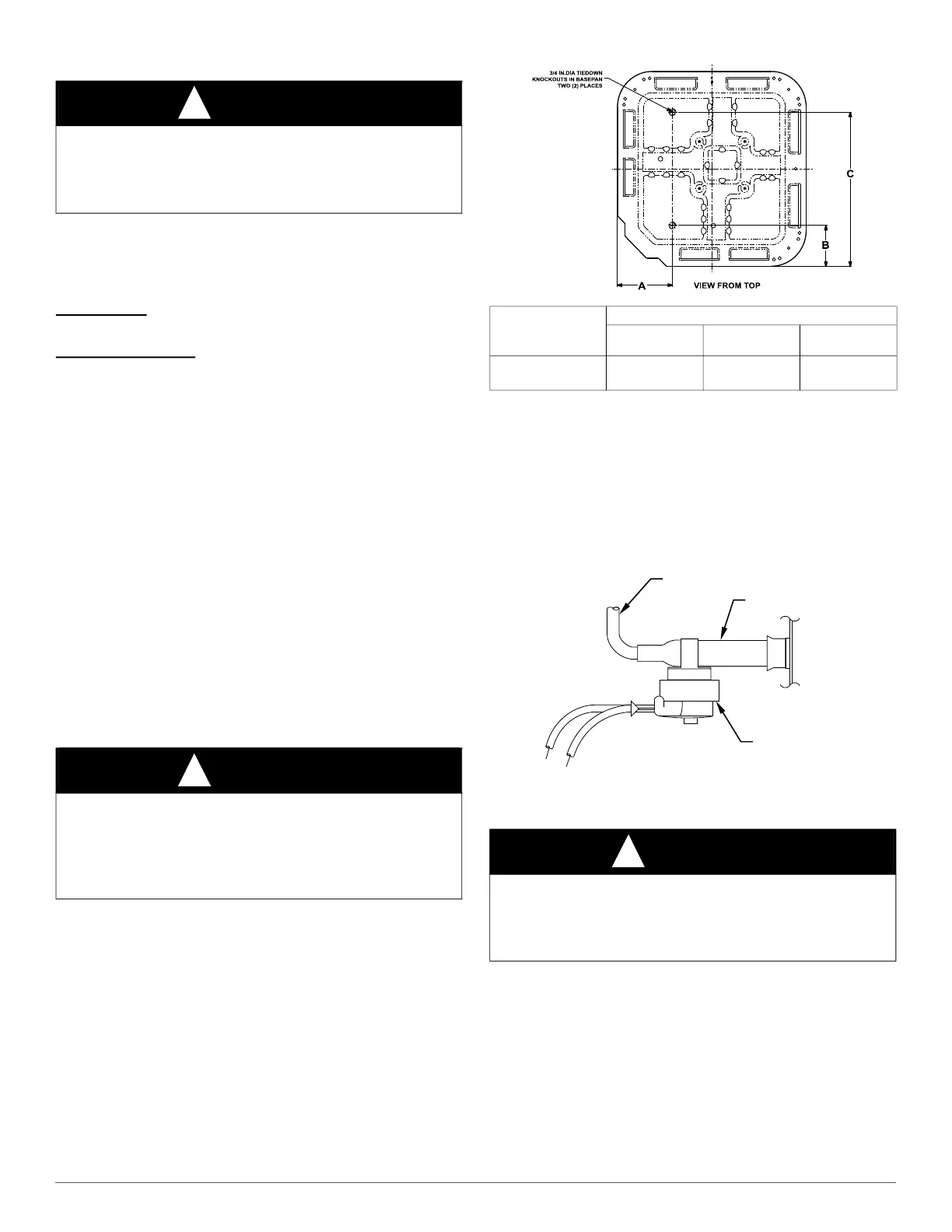

Check Defrost Thermostat

Check defrost thermostat to ensure it is properly located and securely

attached. There is a liquid header with a distributor and feeder tube

going into outdoor coil. At the end of the one of the feeder tubes, there is

a 3/8 in. O.D. stub tube approximately 2 in. long. (See Fig. 3.) The

defrost thermostat should be located on stub tube. Note that there is only

one stub tube used with liquid header, and on most units it is the bottom

circuit.

A97517

Fig. 3 – Defrost Thermostat Location

Elevate Unit

Elevate unit per local climate and code requirements to provide

clearance above estimated snowfall level and ensure adequate drainage

of unit.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing and gloves when handling parts.

CAUTION

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Locate the unit in such a way that it is stable in all circumstances

including adverse weather conditions.

UNIT BASE PAN

Dimension in.

(mm)

TIEDOWN KNOCKOUT LOCATIONS in. (mm)

A B C

35 X 35

(889 X 889)

9–1/8 (231.8) 6–9/16 (166.7) 28–7/16 (722.3)

CAUTION

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not allow water and/or ice to build up in base pan.

FEEDER TUBE

DEFROST

THERMOSTAT

A97517

STUB TUBE

COIL

Loading...

Loading...