GH7T: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

6

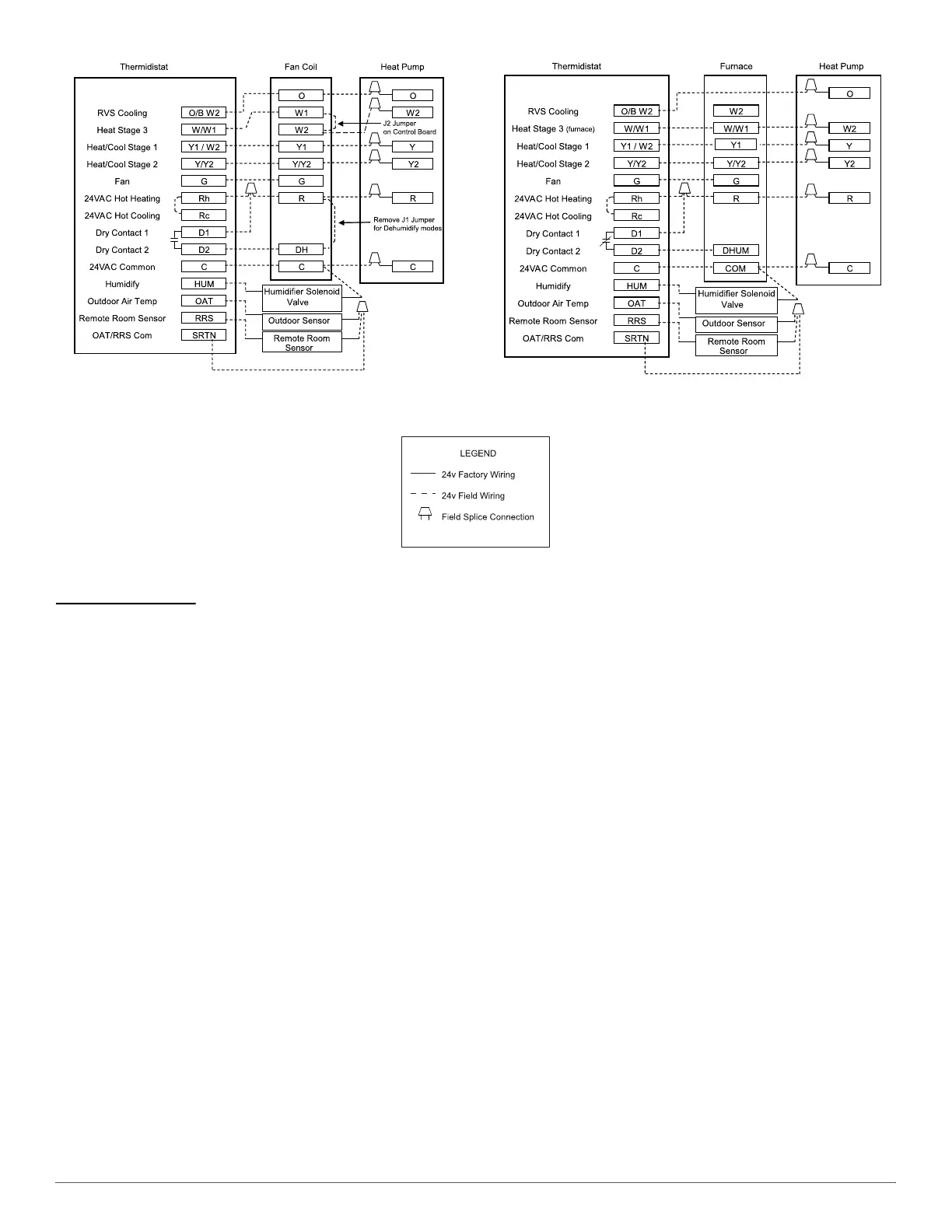

A12258

Fig. 9 – Thermidistat Wiring with Fan Coil

and 2-Stage Heat Pump

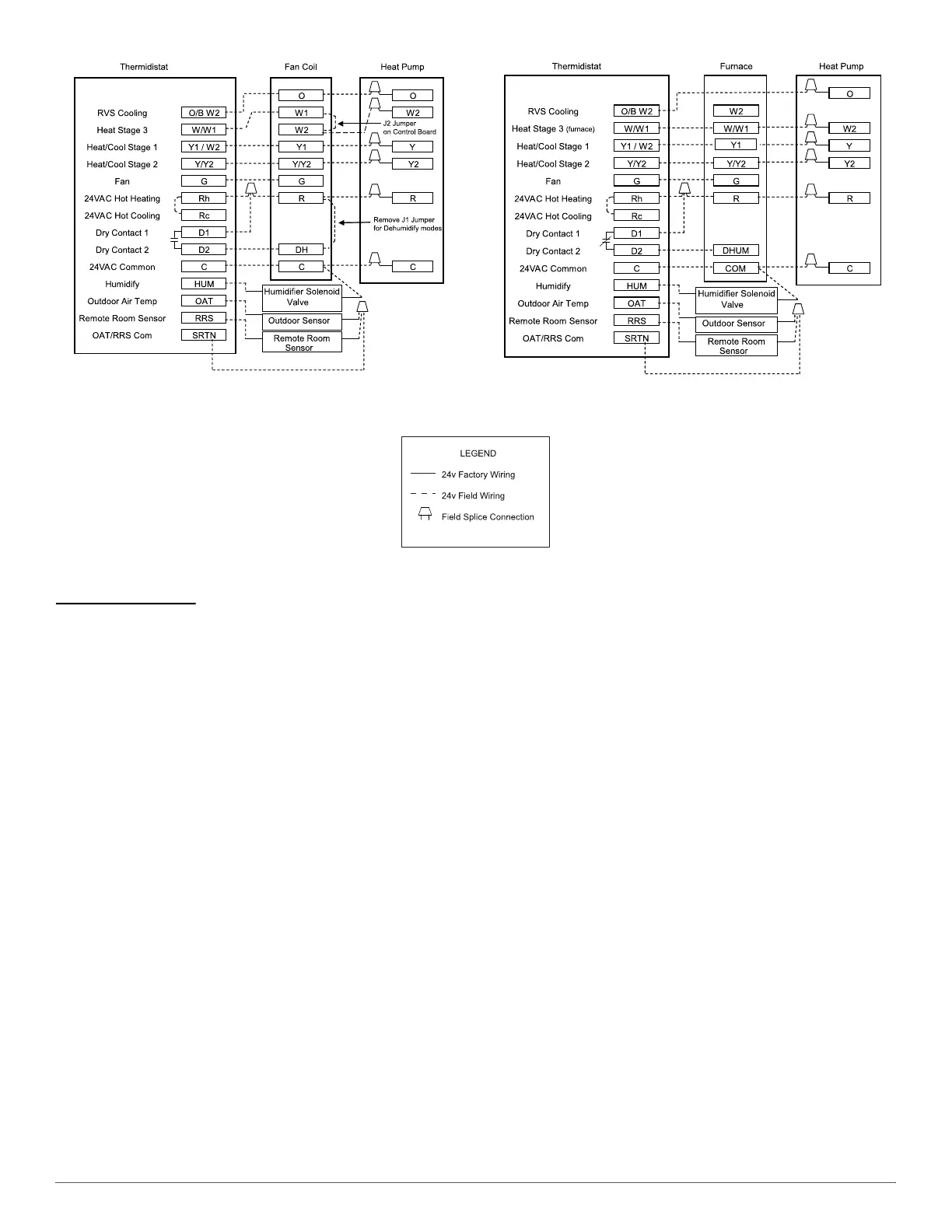

A12259

Fig. 10 – Thermidistat with Variable Speed Furnace

and 2--Stage Heat Pump

A09306

Final Wiring Check

IMPORTANT: Check factory wiring and field wire connections to

ensure terminations are secured properly. Check wire routing to ensure

wires are not in contact with tubing, sheet metal, etc.

Compressor Crankcase Heater

All sizes are equipped with a crankcase heater. Furnish power to heater a

minimum of 24 hours before starting unit. To furnish power to heater

only, set thermostat to OFF and close electrical disconnect to outdoor

unit.

A crankcase heater is required if refrigerant tubing is longer than 80 ft.

(24.4 m), or when outdoor unit is 20 ft. (6.1 m) below the indoor unit.

Refer to the Residential Piping and Long Line Guideline.

Install Electrical Accessories

Refer to the individual instructions packaged with kits or accessories

when installing.

Airflow Selections (ECM Furnaces)

The ECM Furnaces provide blower operation to match the capacities of

the compressor during high and low stage cooling operation. Tap

selections on the furnace control board enable the installing technician to

select the proper airflows for each stage of cooling. Below is a brief

summary of the furnace airflow configurations

1. The Y2 call for high stage cooling energizes the “Cool” tap on the

control board. The grey wire from cool tap is connected to tap 5 on

the motor. Refer to the furnace Product Data to find the

corresponding airflow. If the airflow setting for high cooling needs

to be switched from tap 5 to a different tap, jumper a connection

from the cool tap to the desired tap so that the Y2 signal is

communicated via the cool tap to the desired speed tap.

2. The Y1 call for low stage cooling energizes the “Fan” tap on the

control board. The red wire from the fan tap is connected to tap 1 on

the motor. Refer to the furnace Product Data to find the

corresponding airflow. If the airflow setting for low cooling needs

to be switched from tap 1 to a different tap, jumper a connection

from the Fan tap to the desired tap so that the Y1 signal is

communicated via the Fan tap to the desired speed tap. The Y1

setting will also govern the continuous fan airflow for the furnace.

Refer to the literature for the furnace for further details.

Airflow Selection for Variable Speed Furnaces

(non-communicating)

The variable speed furnaces provide blower operation to match the

capacities of the compressor during high and low stage cooling

operation. The furnace control board allows the installing technician to

select the proper airflows for each stage of cooling. Below is a summary

of required adjustments. See furnace installation instructions for more

details:

1. Turn SW1-5 ON for 400 CFM/ton airflow or OFF for 350 CFM/ton

airflow. Factory default is OFF.

2. The A/C DIP switch setting determines airflow during high stage

cooling operation. Select the A/C DIP switch setting corresponding

to the available airflow shown in the furnace Installation

Instructions that most closely matches the required airflow shown

in the air conditioning Product Data for HIGH speed.

3. The CF DIP switch setting determines airflow during low stage

cooling operation. Select the CF DIP switch setting corresponding

to the available airflow shown in the furnace installation

instructions that most closely matches the required airflow shown

in the air conditioning Product Data for LOW speed. If a higher or

lower continuous fan speed is desired, the continuous fan speed can

be changed using the fan switch on the thermostat. Refer to the

furnace Installation Instructions for details of how to use this

feature.

Loading...

Loading...