GH7T: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

In Long-Line Applications, Install Liquid-Line

Solenoid Valve (LSV)

For refrigerant piping arrangements with equivalent lengths greater than

80 ft. (24.38 m) and/or when elevation difference between indoor and

outdoor unit is greater than ±20 ft. (±6.10 m), follow all requirements of

the Residential Piping and Long-Line Guideline. If required by

Long-Line Guideline, install LSV kit, part no. KHALS0401LLS,

specifically designed for R-410A refrigerant heat pumps. LSV should be

installed within 2 ft. (0.61 m) of outdoor unit with flow arrow pointing

toward outdoor unit. Follow the Installation Instructions included with

accessory kit.

IMPORTANT: Flow arrow must point toward outdoor unit.

Make Piping Connections

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct size

and condition. For tubing requirements beyond 80 ft (24.4 m),

substantial capacity and performance losses can occur. Following the

recommendations in the Residential Piping and Long Line Guideline

will reduce these losses. Refer to Table 1 for accessory requirements.

Refer to Table 2 for field tubing diameters.

There are no buried-line applications greater than 36 in. (914.4 mm)

If refrigerant tubes or indoor coil are exposed to atmosphere, they must

be evacuated to 500 microns to eliminate contamination and moisture in

the system.

Outdoor Unit Connected to Factory Approved Indoor

Unit:

Outdoor unit contains the correct system refrigerant charge for operation

with factory approved, AHRI rated, indoor unit with highest sales

volume when connected by 15 ft (4.57 m) of field-supplied or factory

accessory tubing and factory-supplied filter drier. Check refrigerant

charge for maximum efficiency.

Service Valves

Service valves are closed and plugged from the factory. Outdoor units

are shipped with a refrigerant charge sealed in the unit. Leave the service

valves closed until all other refrigerant system work is complete or the

charge will be lost. Leave the plugs in place until line set tubing is ready

to be inserted.

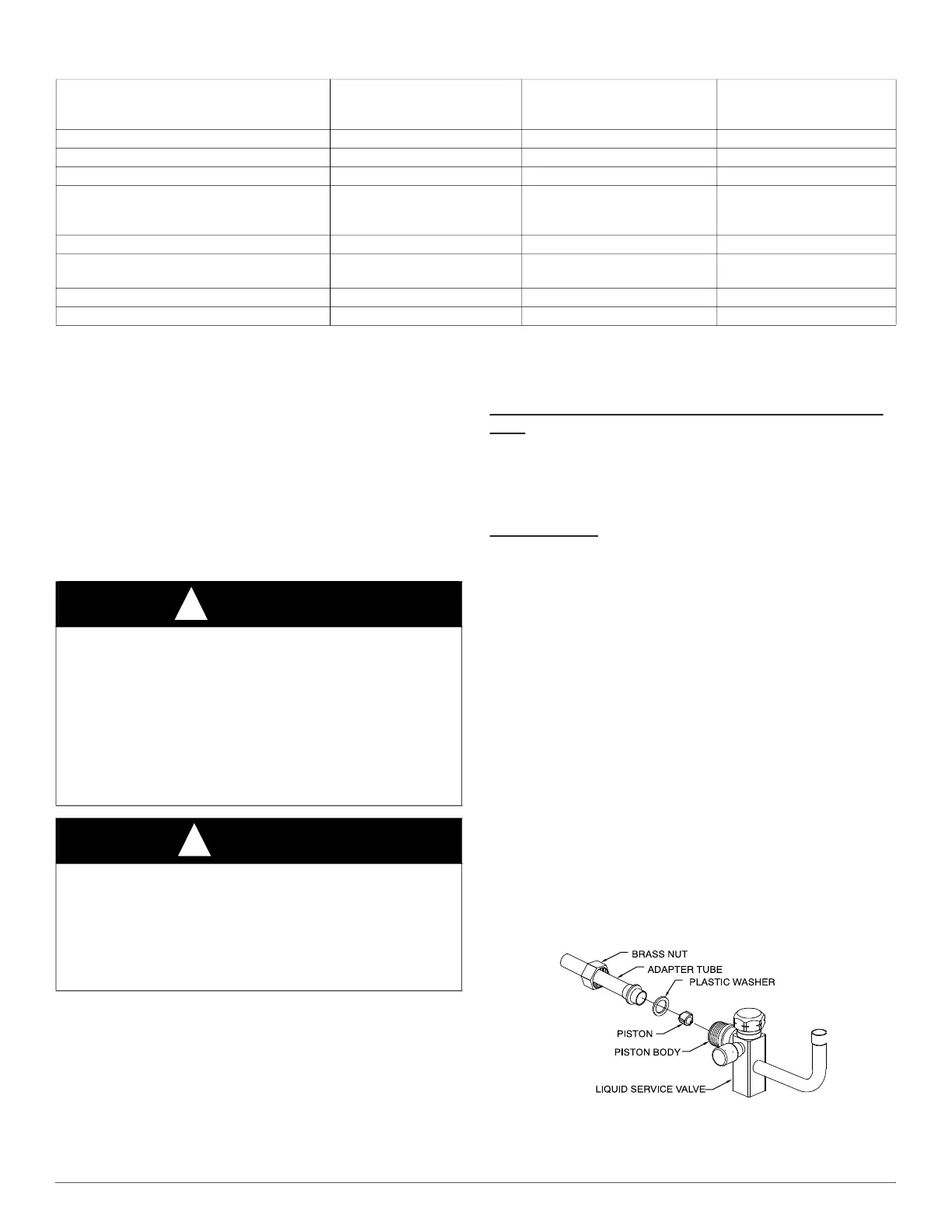

Heat pumps require a piston metering device in the liquid service valve

for proper heating operation. Piston is shipped in the piston body of the

liquid service valve, temporarily held in place with a plastic cap. Do not

remove the plastic cap until line set tubing is ready to be installed.

Refer to Fig. 4 and follow these steps for piston installation:

1. Remove plastic cap holding piston in piston body of liquid service

valve.

2. Check that piston size (stamped on side of piston) matches with

number listed on unit rating plate. Return piston to piston body of

liquid service valve (either direction).

3. Find plastic bag taped to unit containing copper adapter tube, brass

nut, and plastic washer.

4. Install plastic washer in the seat inside piston body.

5. Fit brass nut onto adapter tube and install tube onto liquid service

valve. Tighten nut finger tight, then wrench additional ½ turn only

[15-ft lbs (20.3 N-m)]. Over tightening may damage the plastic

washer and service valve’s piston body.

A14235

Fig. 4 – Liquid Service Valve with Heating Piston and Adapter Tube

Table 1 – Accessory Usage

Accessory

Required for Low Ambient

Cooling Applications

(Below 55°F / 12.8°C)

Required for Long Line

Applications

*

*. For tubing line sets between 80 and 200 ft. (24.38 and 60.96 m) and/or 20 ft. (6.09 m) vertical differential, refer to Residential Piping and Longline Guideline.

Required for Sea Coast

Applications

(within 2 miles/3.2 km)

Compressor Start Assist Capacitor and Relay Yes Yes No

Crankcase Heater Yes (standard) Yes (standard) No

Evaporator Freeze Thermostat Yes No No

Hard Shutoff TXV

Yes

(standard w/factory approved

indoor unit)

Yes

(standard w/factory approved

indoor unit)

Yes

(standard w/factory approved

indoor unit)

Isolation Relay Yes No No

Liquid Line Solenoid Valve No

See Residential Piping

and Long Line Guideline

No

Low-Ambient Pressure Switch Yes No No

Support Feet Recommended No Recommended

WARNING

!

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal injury or death.

Relieve pressure and recover all refrigerant before system repair or

final unit disposal.

Use all service ports and open all flow-control devices, including

solenoid valves.

Federal regulations require that you do not vent refrigerant into the

atmosphere. Recover refrigerant during system repair or final unit

disposal

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

If ANY refrigerant tubing is buried, provide a 6-in (152.4 mm). vertical

rise at service valve. Refrigerant tubing lengths up to 36-in (914.4

mm). may be buried without further special consideration. Do not bury

lines longer than 36 in (914.4 mm).

Loading...

Loading...