25TPB7: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

11

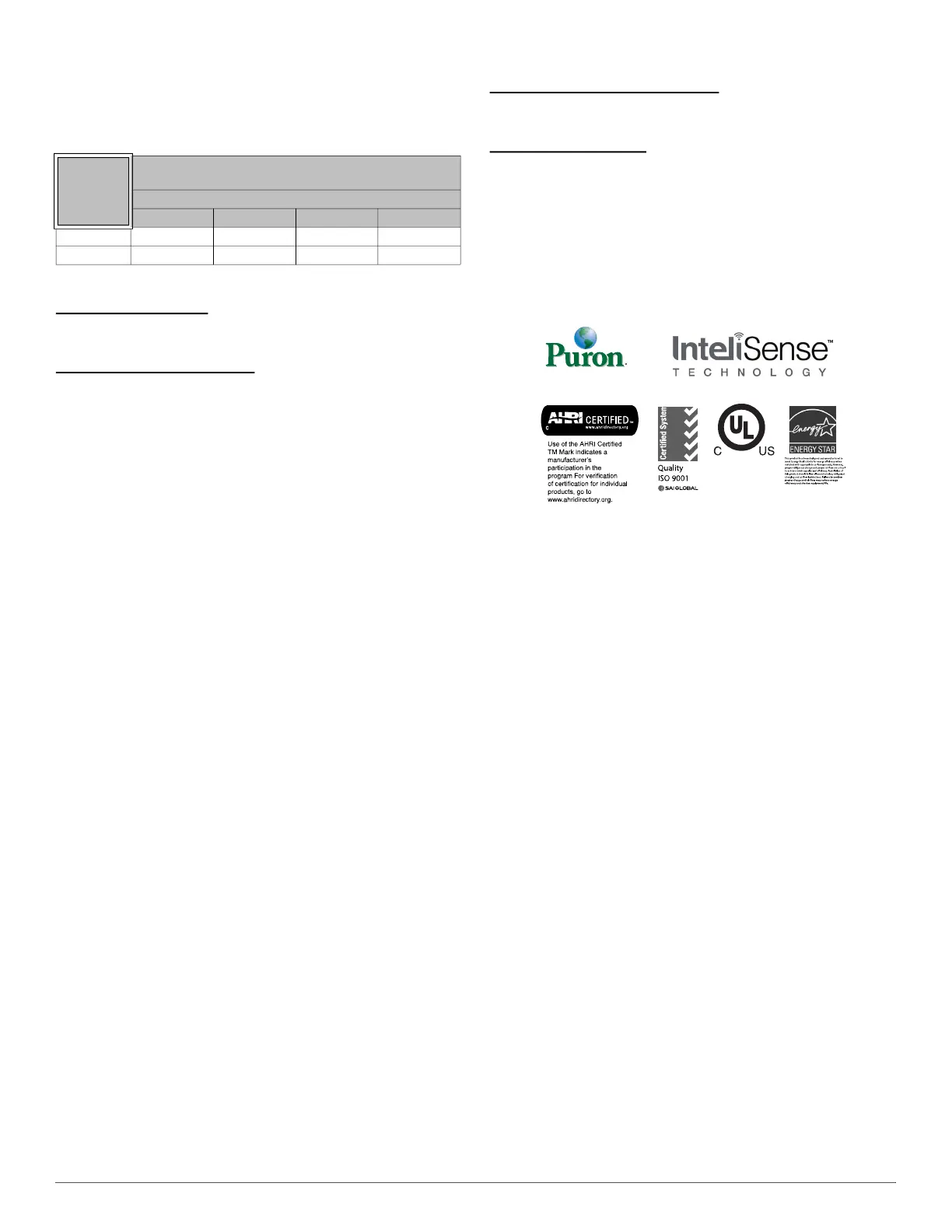

Troubleshooting

If the compressor fails to operate with a cooling call, the table below

(Resistance table) can be used to verify if there is any damage to the

compressor windings causing system malfunction.

Major Components

2-Stage Compressor

The 2-stage compressor contains motor windings that provide 2-pole

(3500 RPM) operation.

Compressor Internal Relief

The compressor is protected by an internal pressure relief (IPR) which

relieves discharge gas into compressor shell when differential between

suction and discharge pressures exceeds and 550 - 625 psi. The

compressor is also protected by an internal overload attached to motor

windings.

Compressor Control Contactor

The contactor has a 24 volt coil and is controlled by Y1 input from the

thermostat

Low Pressure Switch

Low pressure switch is provided in line with the Y1 signal to the

contactor for protection.

Care and Maintenance

For continuing high performance and to minimize possible equipment

failure, periodic maintenance must be performed on this equipment.

Frequency of maintenance may vary depending upon geographic areas,

such as coastal applications. See Users Manual for information.

Training

My Learning Center is your central location for professional residential HVAC training resources that help strengthen careers and businesses. We

believe in providing high quality learning experiences both online and in the classroom.

Access My Learning Center with your HVACpartners credentials at www.mlctraining.com. Please contact us a mylearning@carrier.com with

questions.

Table 3 – Winding Resistance

Winding

Winding resistance at 70°F +/- 20°F

(21.11°C +/- 11.11°C)

Unit Size

024 036 048 060

Start (S-C) 1.652 1.587 1.299 1.203

Run (R-C) 1.065 0.751 0.477 0.383

Loading...

Loading...