PHJ4 and WJH4: Owner’s Information Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

airflow across the coil and reduce the amount of heat absorbed from the

outside air. So, to maintain energy-efficient operation, your unit has an

automatic defrost mode.

The defrost mode starts at a preset time interval of 60 minutes, although,

it may be reset to 30, 90 or 120 minutes. Defrost will start at the preset

time only if the ice is sufficient to interfere with normal heating

operation.

After the ice is melted from the coil, or after a maximum of 10 minutes

in defrost mode, the unit automatically switches back to normal heating

operation.

Do not be alarmed if steam or fog appears at the outdoor unit during

defrost mode. Water vapor from the melting ice may condense into a

mist in the cold outside air.

During certain weather conditions such as heavy snow and freezing rain

it is not uncommon for ice to build up on the unit grille. This is normal

for these weather conditions. Do not attempt to remove the ice from the

unit grille. This condition will not affect the proper function of the unit

and will clear within a few days.

During defrost mode, your heat pump will automatically turn on the

supplemental heat, if equipped. You may notice the indoor fan increase

its speed.

Emergency Heating Mode

In the event of primary unit heat failure, the emergency heat mode

allows your supplemental heating source to keep your home or office

warm until your unit can be serviced. Contact your dealer in the event of

primary unit heat failure.

During Emergency Heat, your thermostat will lockout the heat pump and

turn on the supplemental heat, if equipped. You may notice the indoor

fan increase its speed.

Maintenance and Service

This section discusses maintenance that should be performed by your

dealer and care you, as the owner, may wish to handle for your new unit.

Routine Maintenance

All routine maintenance should be handled by skilled, experienced

personnel. Your dealer can help you establish a standard procedure.

To assure proper functioning of the unit, flow of condenser air must not

be obstructed from reaching the unit. Clearance from the top of the unit

is 48 in. (1219 mm). Clearance of at least 36 in. (914 mm) is required on

sides except the power entry side (42 in. [1067 mm] clearance).

Maintenance and Care for the Equipment Owner

Before proceeding with those things you might want to maintain

yourself, please carefully consider the following:

Air Filters

The air filter(s) should be checked every 3 or 4 weeks and changed or

cleaned whenever it becomes dirty. Dirty filters produce excessive stress

on the blower motor and can cause the motor to overheat and shut down.

This unit must have an air filter in place before it can be operated. These

filters should be located in at least one of two places. In many

applications, the installer will provide return air filter grilles mounted on

the wall or ceiling of the conditioned structure. In the instance of filter

grilles, the filters can simply be removed from the grille and replaced.

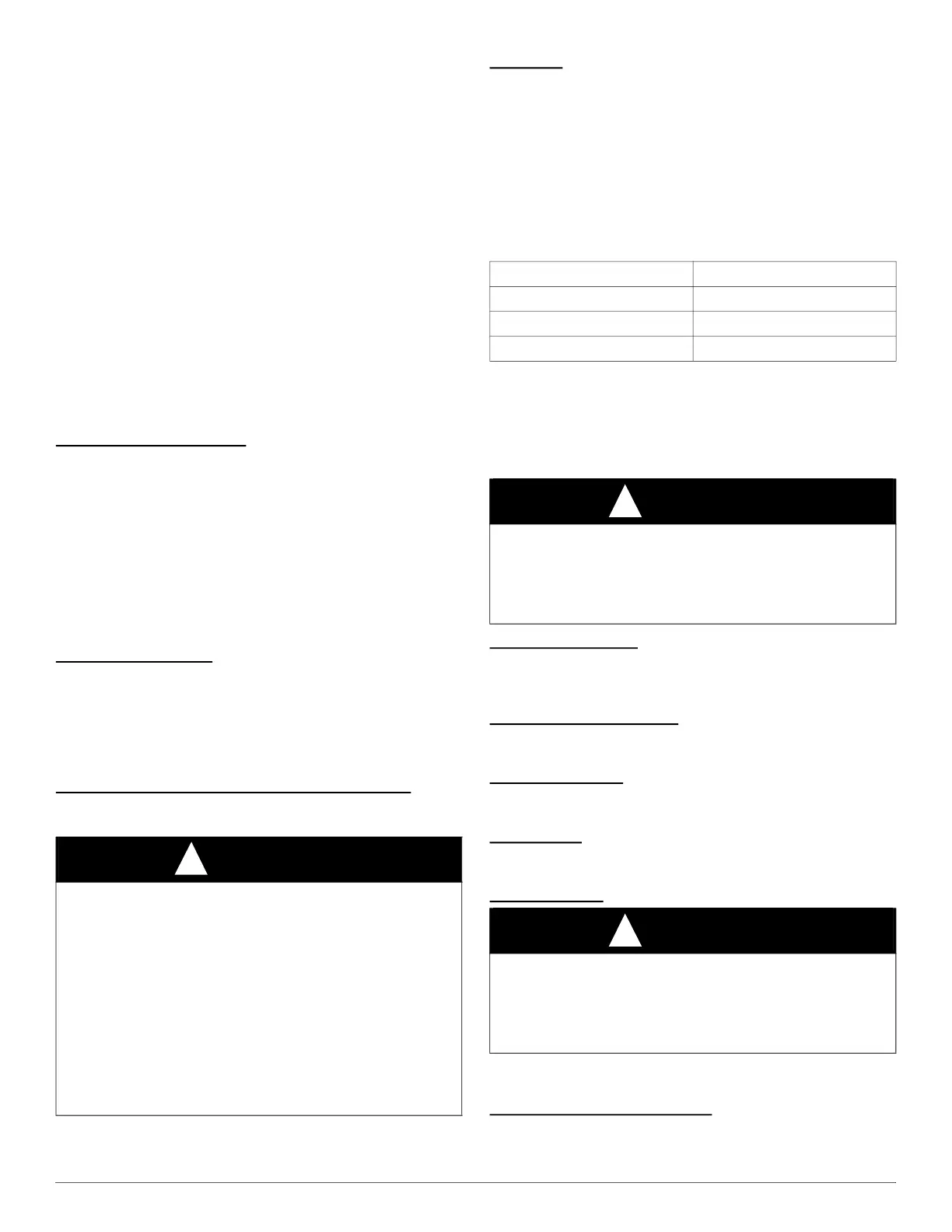

Table 1 indicates the correct indoor filter size for your unit.

When installing the new filter(s), note the direction of the airflow arrows

on the filter frame.

If you have difficulty locating your air filter(s) or have questions

concerning proper filter maintenance, contact your dealer for

instructions. When replacing filters, always use the same size and type of

filter that was supplied originally by the installer.

Fans and Fan Motor

Periodically check the condition of fan wheels and housings and

fan-motor shaft bearings. Contact your dealer for the required annual

maintenance.

Indoor and Outdoor Coils

Cleaning of the coils should only be done by qualified service personnel.

Contact your dealer for the required annual maintenance.

Condensate Drain

The drain pan and condensate drain line should be checked and cleaned

at the same time the cooling coils are checked by your dealer.

Compressor

All compressors are hermetically sealed and do not require periodic

maintenance.

Condenser Fan

The fan must be kept free of all obstructions to ensure proper cooling.

Contact your dealer for any required service.

Electrical Controls and Wiring

Electrical controls are difficult to check without proper instrumentation.

If there are any discrepancies in the operating cycle, contact your local

dealer and request service.

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, CUT

HAZARD

Failure to follow this warning could result in personal injury, death or

property damage.

1. TURN OFF ELECTRICAL POWER TO YOUR UNIT

BEFORE SERVICING OR PERFORMING MAINTENANCE

AND INSTALL A LOCK-OUT TAG.

2. When removing access panels or performing maintenance

functions inside your unit, be aware of sharp sheet metal parts

and screws. Although special care is taken to reduce sharp

edges to a minimum, be extremely careful when handling parts

or reaching into the unit.

Table 1 – Indoor Air Filter Data

Unit Size Filter Size

024 20x20x1 (508x508x25 mm)

030-036 24x30x1 (610x762x25 mm)

042-060 24x36x1 (610x914x25 mm)

WARNING

!

FIRE AND UNIT OPERATION HAZARD

Failure to follow this warning could result in personal injury, death or

property damage.

Never operate your unit without filters in place. An accumulation of

dust and lint on internal parts of your unit can cause loss of efficiency.

WARNING

!

PERSONAL INJURY AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury, death or

property damage.

Do not poke sticks, screwdrivers, or any other object into revolving fan

blades.

Loading...

Loading...