30

4. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

NOTE: Pressure test the gas supply system after the gas supply

piping is connected to the gas valve. The supply piping must be

disconnected from the gas valve during the testing of the piping

systems when test pressure is in excess of 0.5 psig (3450 Pa). Pres-

sure test the gas supply piping system at pressures equal to or less

than 0.5 psig (3450 Pa). The unit heating section must be isolated

from the gas piping system by closing the external main manual

shutoff valve and slightly opening the ground-joint union.

Check for gas leaks at the field-installed and factory-installed

gas lines after all piping connections have been completed. Use

soap-and-water solution (or method specified by local codes

and/or regulations).

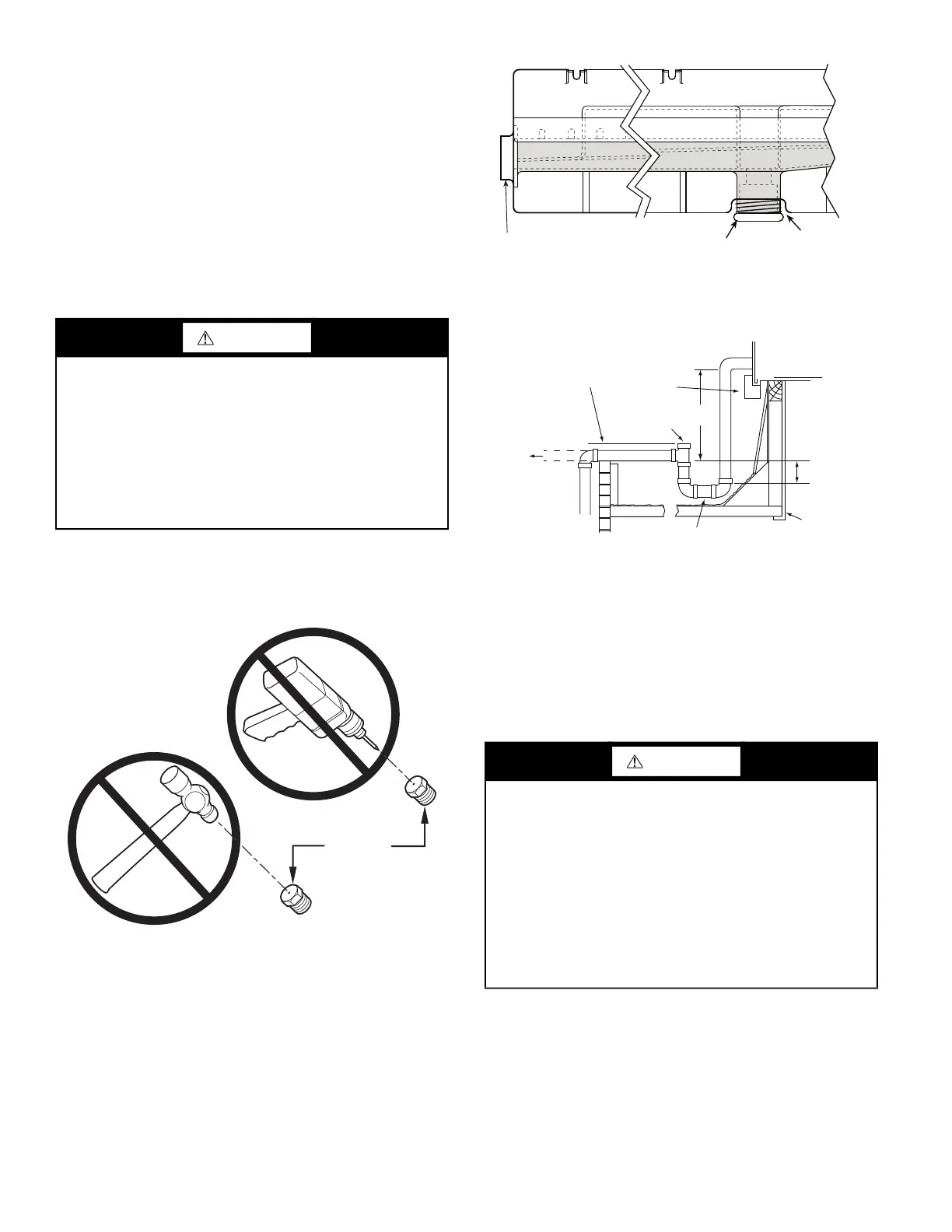

NOTE: If orifice hole appears damaged or it is suspected to have

been re-drilled, check orifice hole with a numbered drill bit of cor-

rect size. Never re-drill an orifice (see Fig. 43). A burr-free and

squarely aligned orifice hole is essential for proper flame charac-

teristics.

Fig. 43 — Orifice Hole

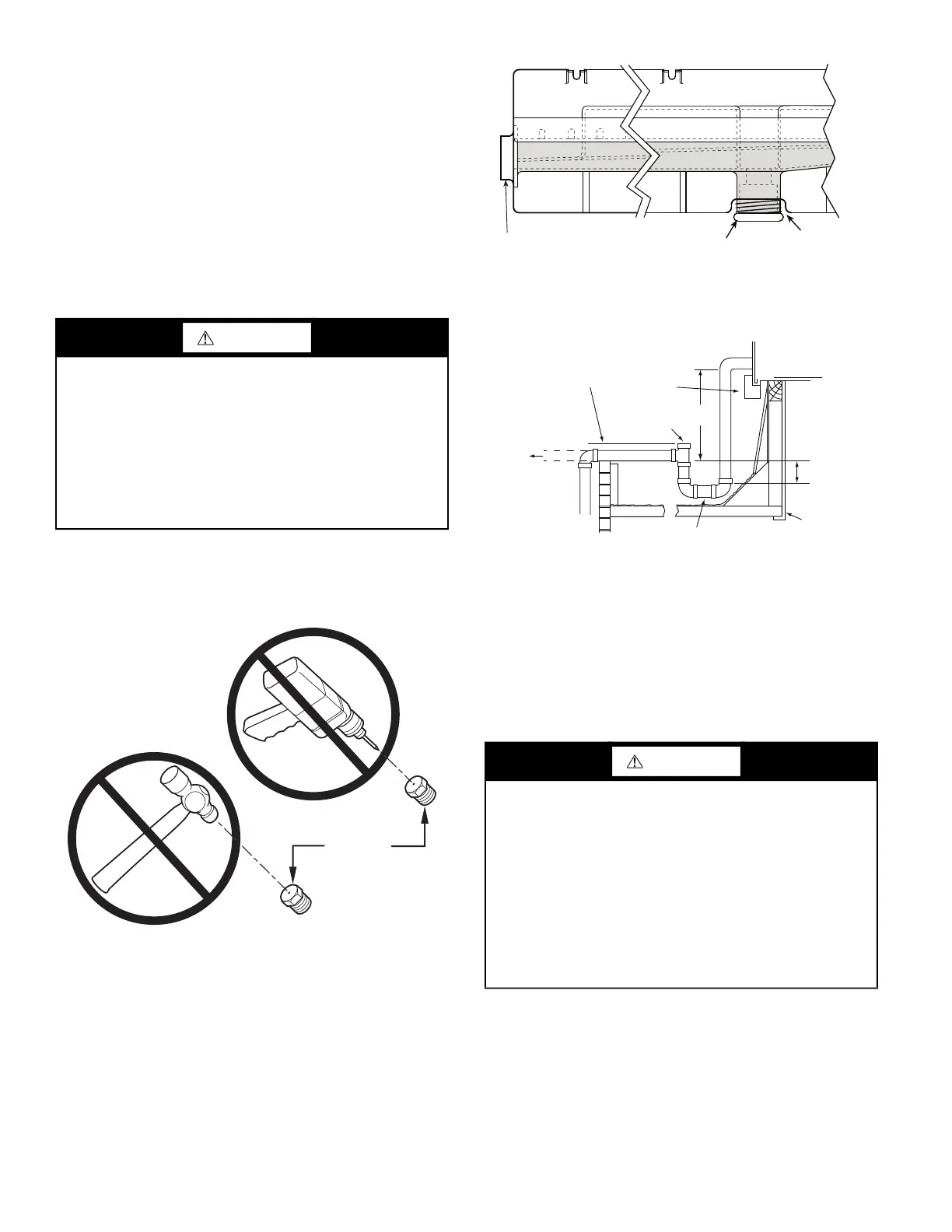

Step 11 — Install External Condensate Trap and

Line

The unit has one

3

/

4

-in. condensate drain connection on the end of

the condensate pan and an alternate connection on the bottom. See

Fig. 44. Unit airflow configuration does not determine which

drain connection to use. Either drain connection can be used with

vertical or horizontal applications.

To use the alternate bottom drain connection, remove the red drain

plug from the bottom connection (use a

1

/

2

-in. square socket drive

extension) and install it in the side drain connection.

The piping for the condensate drain and external trap can be com-

pleted after the unit is in place. See Fig. 44 and 45.

Fig. 44 — Condensate Drain Pan (Side View)

NOTE: If the alternate bottom drain is not used, check the drain

plug for tightness prior to setting the unit on the roof curb.

Fig. 45 — Condensate Drain Piping Details

All units must have an external trap for condensate drainage. In-

stall a trap at least 4-in. (102 mm) deep and protect against freeze-

up. If drain line is installed downstream from the external trap,

pitch the line away from the unit at 1-in. per 10 ft (25 mm in 3 m)

of run. Do not use a pipe size smaller than the unit connection

(

3

/

4

-in.).

Step 12 — Make Electrical Connections

NOTE: Field-supplied wiring shall conform with the limitations

of minimum 63°F (33°C) rise.

FIELD POWER SUPPLY (SIZES 07-14)

If equipped with optional powered convenience outlet: The power

source leads to the convenience outlet’s transformer primary are

not factory connected. Installer must connect these leads accord-

ing to required operation of the convenience outlet. If an always-

energized convenience outlet operation is desired, connect the

source leads to the line side of the unit-mounted disconnect.

(Check with local codes to ensure this method is acceptable in

WARNING

Failure to follow this warning could result in personal injury,

death and/or property damage.

• Connect gas pipe to unit using a backup wrench to

avoid damaging gas controls.

• Never purge a gas line into a combustion chamber.

• Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections.

• Use proper length of pipe to avoid stress on gas control

manifold.

BURNER

ORIFICE

WARNING

Failure to follow this warning could result in personal injury or

death.

Do not use gas piping as an electrical ground.

Unit cabinet must have an uninterrupted, unbroken electrical

ground to minimize the possibility of personal injury if an

electrical fault should occur. This ground may consist of elec-

trical wire connected to unit ground lug in control compart-

ment, or conduit approved for electrical ground when installed

in accordance with NEC (National Electrical Code); ANSI/

NFPA 70, latest edition (in Canada, Canadian Electrical Code

CSA [Canadian Standards Association] C22.1), and local elec-

trical codes.

DRAIN

(FACTORY-INSTALLED)

PLUG

CONDENSATE PAN (SIDE VIEW)

STANDARD

SIDE DRAIN

ALTERNATE

BOTTOM DRAIN

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4-in. (102 mm) trap is recommended.

MINIMUM PITCH

1˝ (25 mm) PER

10´ (3 m) OF LINE

BASE RAIL

OPEN

VENT

TO ROOF

DRAIN

DRAIN PLUG

ROOF

CURB

SEE NOTE

3˝ (76 mm)

MIN

Loading...

Loading...