SECTION 2 - CONTROLS, INSTRUMENTS AND OPERATION

2ï4

5

The plunger moves the charge flake back and

compresses it against the bale to be formed in the

bale chamber. Both bale chamber side doors (6) and

top door (5) are hinged and can move under the

action of two density cylinders (8). This is to modify

the outlet section of the bale chamber and thus to

control the density of the bales produced. An

electronic system measures the load on the plunger

when pushing material rearwards. The electronic

system will control the hydraulic bale density system

until the load measured is the same as the density

value pre-set by the operator. That value must be

chosen in relation to the nature and to the moisture

content of the crop to be baled, as well as the bale

density required.

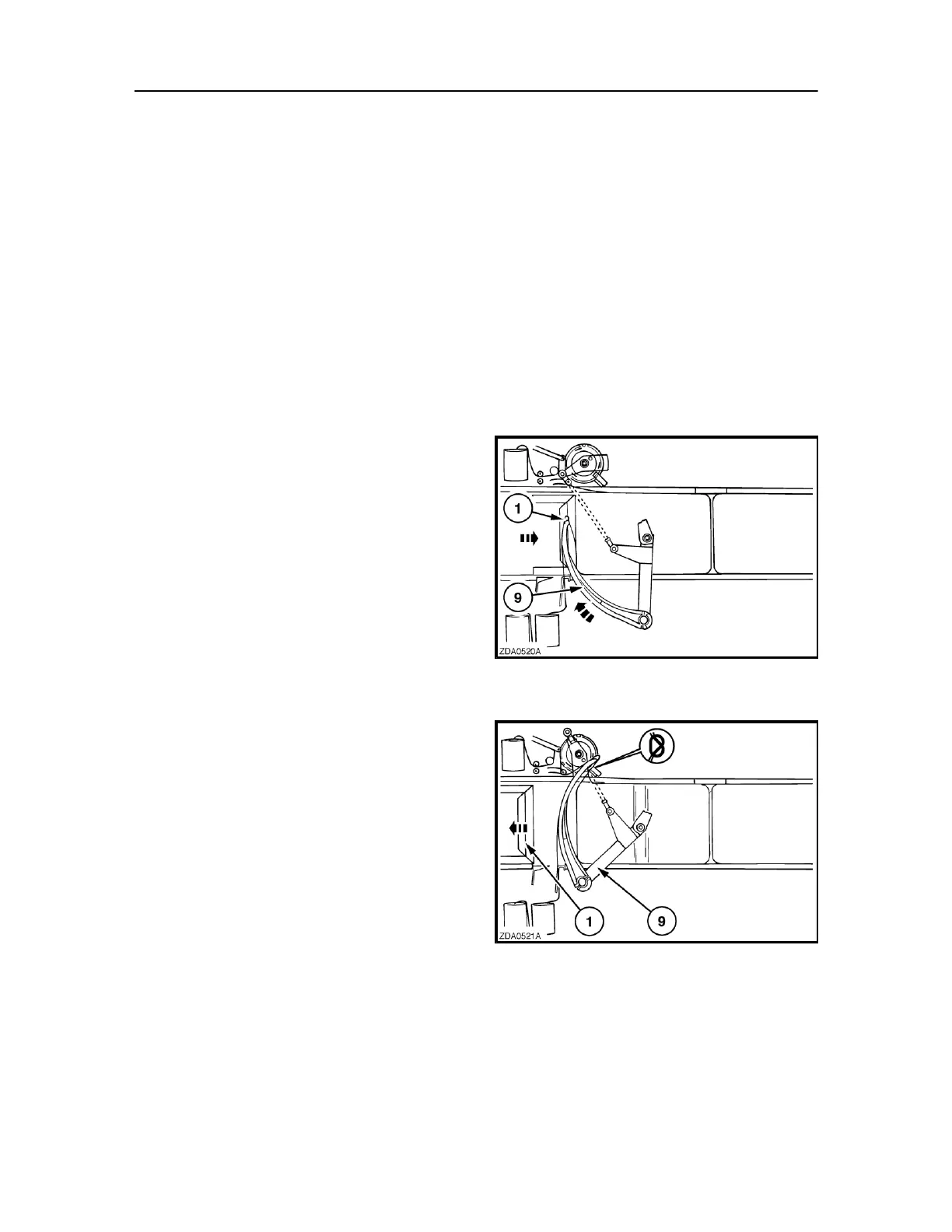

While the bale travels rearward in the bale chamber,

it activates bale length metering wheel (4). When the

desired bale length is reached, a mechanism will trip

knotters (3) and needles (9), which are timed with

baler plunger (1).

6

At each side of the machine, twine balls are provided.

Twine will be fed to the tucker twine arms, located

above the bale chamber, and to needles (9), located

underneath the bale chamber.

During the compression stroke of plunger (1), needles

(9) will raise towards knotters (3), bringing along the

lower twine (Fig. 6).

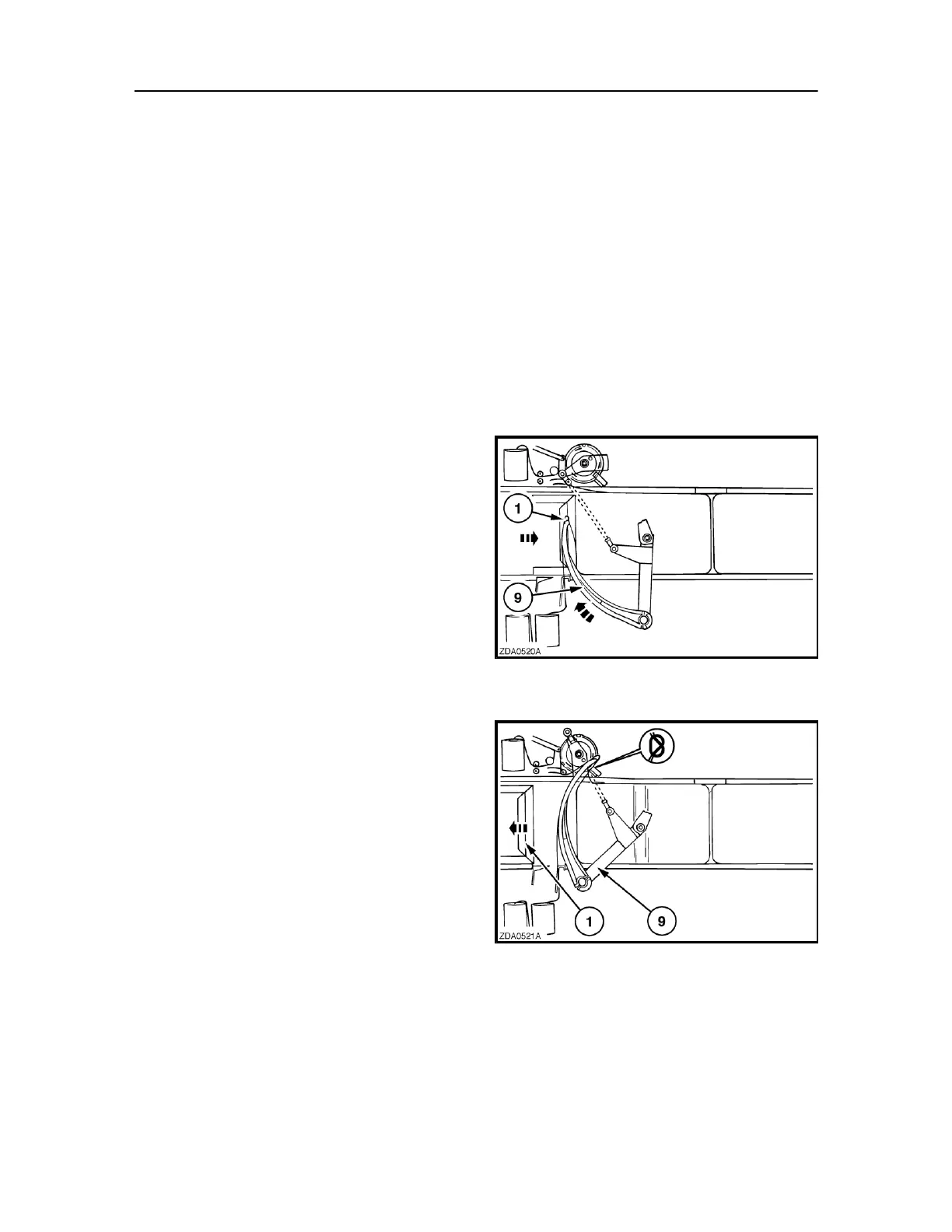

When the needles reach the knotters they will also

pick-up the upper twines. Both twines are laid in the

knotter (Fig. 7), tied together and the ends are cut to

finish the bale (Fig. 8).

7

Loading...

Loading...