INTRODUCTION

STC®disassemblyaction

NOTICE:Donotusethedisconnecttooltopryonthe

parts.Pryingcanresultindamage.Insertthetoolstraight

intotheconnection.Theproperconnectionanddiscon-

nectionofSTC®partsisoutlinedlaterinthissection.

1.Releasepressurefromthehydraulicsystempriorto

disconnectingcomponents.

2.Someuidmaystillbeinthesystem.Minimizeuid

lossbydrainingtheuidfromsystemcomponents

priortodisconnection.

3.Priortodisconnection,cleantheareaaroundthet-

tingswithacleancloth,Orusinganairguntoblowdirt

anddebrisfromthereleasesleevearea.

4.Tohelpavoidthereleasesleevefromtearing,create

an(forthereleasesleeve)insertiongapbymovingthe

sleeveinthereleasedirection.Thiscanbedoneeither

byhandorbyusingasingleprongofthereleasetool.

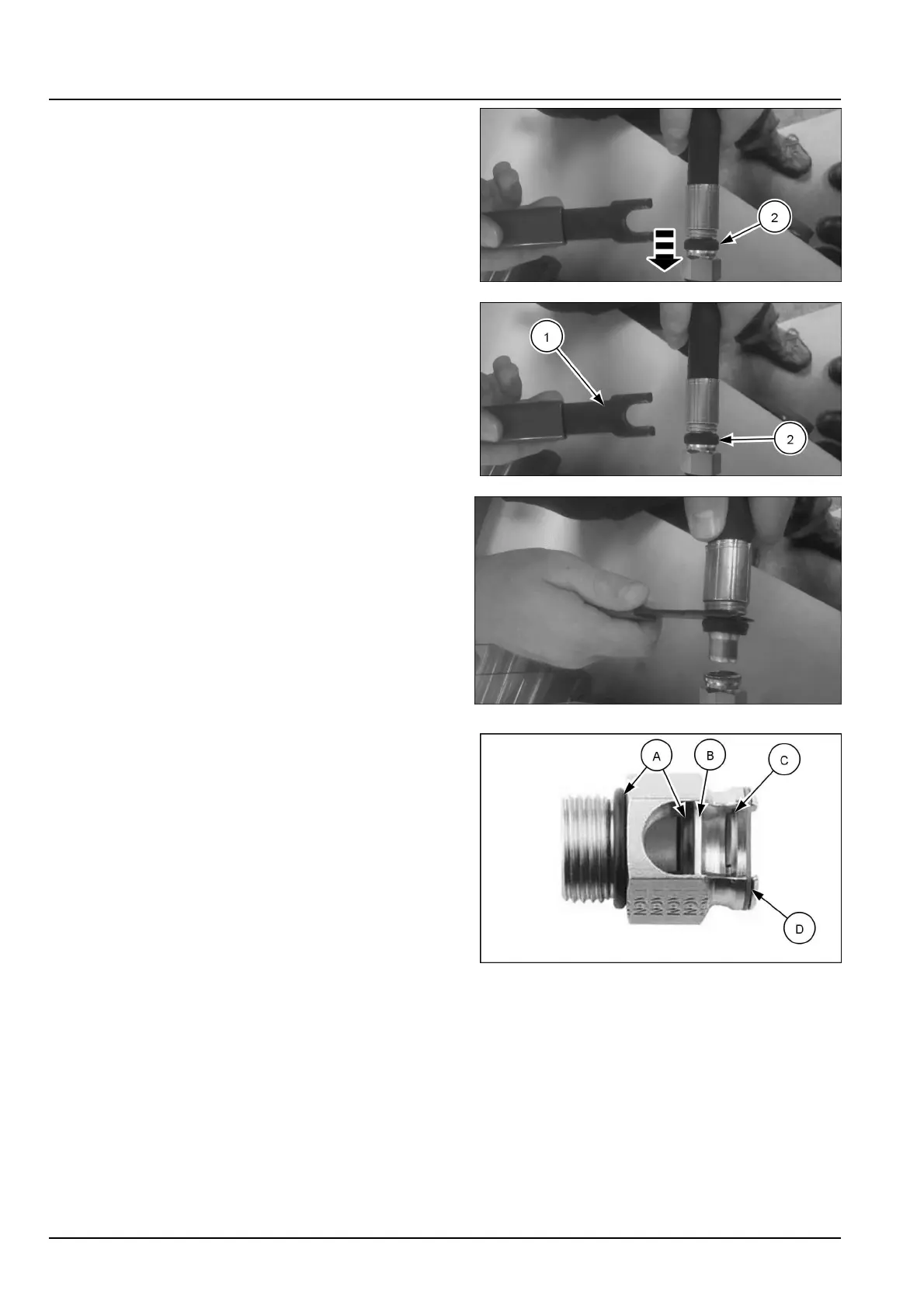

5.AstheSTC®tool(1)isinsertedbehindtherelease

sleeve(2),thesteelinsertpushesthelatchingring

forwardintoagrooveinthefemalehalfI.D.,allowing

thetwohalvestobepulledapart.Thethicknessof

thetoolmovesthesleeveforwardfarenoughtomake

thedisconnection,sopryingsidewayswiththetoolis

unnecessary

RAIL17TLB0465AA10

RAIL17TLB0465AA11

RAIL17TLB0467AA12

Sealreplacementinstructionsinspection

•

InspectmatingSTC®ttingstoensuretheyarein

goodcondition,cleanandfreeofcontaminants,nicks,

scratches,atspots,etc.

•

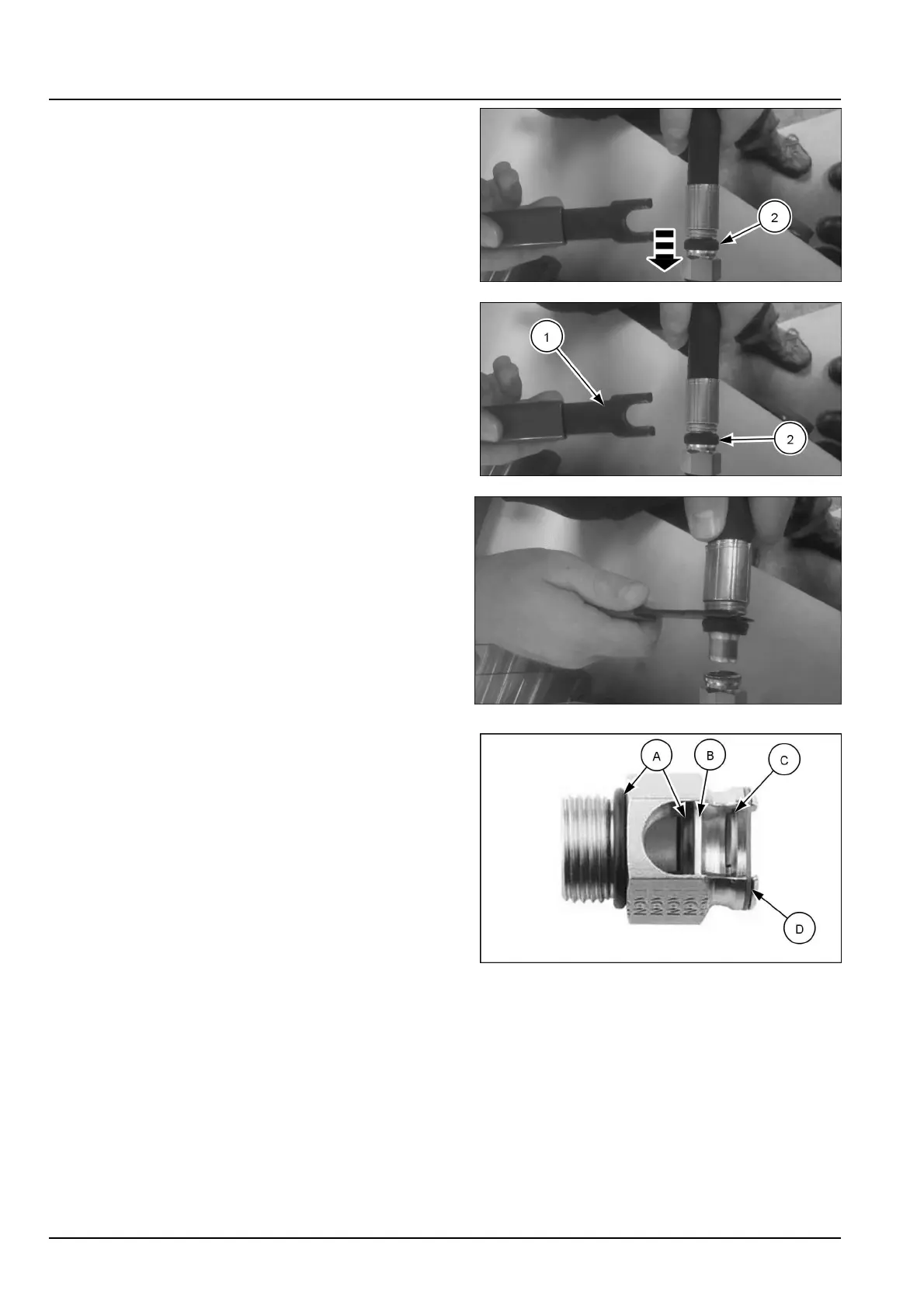

ChecktheLatchRing(C)toensurethatitisinproper

positioninthefemaleSTC®connectorpriortoinstalla-

tionorconnection.

•

ChecktheO-Ring(A)toensureitisnotcutorotherwise

damagedpriortoinstallationorconnection.

•

ChecktheBack-UpRing(B)toensureitisnotdam-

aged.VerifythatitisatthefrontoftheO-Ringgroove

priortoconnectionthetting.

RAIL17TLB0016AA13

•

IfanydamageisdetectedoneitheroftheO-Ring,

Back-UpRingorLatchRing,replacethembyfollowing

theseprocedures:

1.CarefullyremoveO-Ring(A)andBack-UpRing(B)

withanO-Ringpickwithoutdamagingtheinterior

surfacesofthetting.

2.Inspecttheinteriorsurfacesandgroovesofthet-

tingandensurethattheyarefreeofforeignmaterial

ornicks,scratches,dents,etc.

3.Ifundamaged,cleanthettingandinstallthe

Back-UpRing(B)atthefrontoftheO-Ringgroove.

4819455820/10/2017

66

Loading...

Loading...